CONTRIBUTION

AUGUST 2018

Reduce Sand Burn-On Through an Optimized Gate Design

During the casting and solidification process, the mold material is subject to increased thermal loads. Sand burn-on defects can occur at sand edges in particular, where the molding sand and the melt have prolonged contact due to the sand mold geometry. These defects are caused by a reaction between the melt and the mold material (sintering). In addition to the thermal load, the sand quality and the mold material surface (coatings) are other major influencing factors.

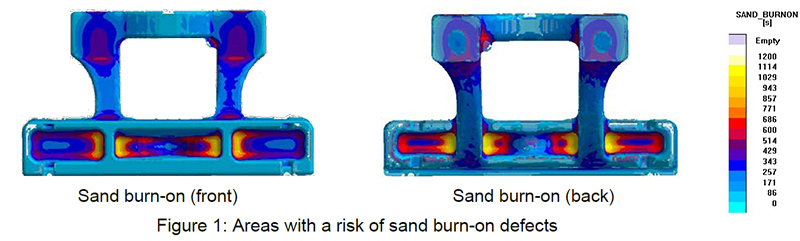

During the production of a gray cast iron bearing bracket, sand burn-on defects occurred in some casting sections, leading to major finishing operations. The simulation clearly reveals the critical areas in the front and back views. Figure 1 shows the time during which the sand surface is above a critical (sintering) temperature.

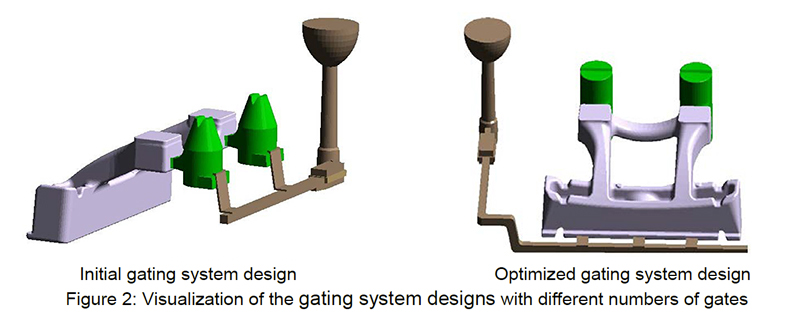

The aim of this project was to achieve a more uniform and overall reduced thermal load for the mold material by optimizing the gate design. For this purpose, the position of the gates was moved from the feeders to the opposite side. In addition, one more gate was introduced to obtain a more uniform distribution both of the melt and of the temperatures in the casting.

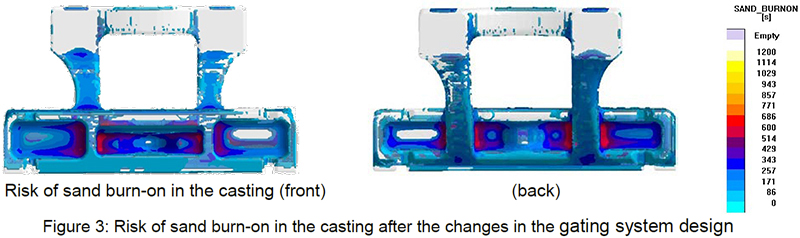

Thanks to the optimized gating system design, the risk of sand burn-on defects in the critical areas could be considerably reduced (see Figure 3).

If you are interested in learning more about the many different options to evaluate simulation results as well as about the possibilities for evaluating casting processes prior to production, book the seminar “Evaluation of Simulation Results” (with the focus on sand casting or high pressure die casting) as an in-house seminar on-site in your company.

This event introduces you to the different simulation results and quality criteria in sand casting/ high pressure die casting and shows you how to evaluate the results and implement them in practice. At the same time, the importance of simulation results for the casting quality as well as their significance for ensuring robust processes is illustrated. Based on practice-related examples, we will guide you through the wide spectrum of available quality criteria and demonstrate how to make efficient use of influencing parameters and correlations from virtual designs of experiments in your company.

Therefore, this interdisciplinary event is primarily aimed at managers and design, quality or purchasing executives, who do not use the software for their work on a daily basis, yet need simulation results for decision-making.  |