Systematic Rigging System Design by Using Virtual Design of Experiments

The interaction between casting, HPDC machine and tool design has a considerable influence on the robustness of the manufacturing conditions and, thus, on the quality of the series production component.

There is a wide range of different quality requirements for the part. To be able to assess all requirements prior to tooling, casting process simulation and the methodology of virtual DoE and autonomous optimization based on it provide crucial support. Both ways allow you to review and evaluate different concepts or alternatives at an early stage. Experimentation on the screen helps with decision-making and supports robust manufacturing conditions.

For the conception and design of casting systems in high pressure die casting, many machine, tool and casting-related influencing parameters need to be considered at an early stage. The virtual design of experiments in MAGMASOFT® allows for an independent variation of these variables.

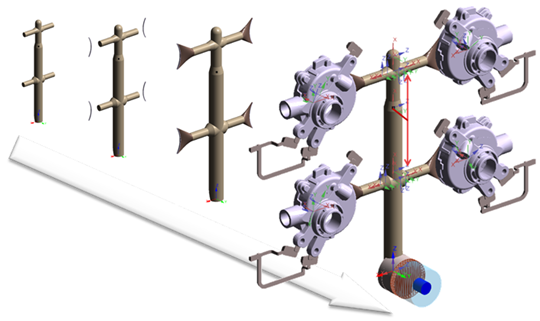

The example below uses a four-cavity tool to show you how to lay out the rigging system in order to achieve a uniform filling of all four cavities. This requires the parametric modeling of the cross-sections of the runner geometry in MAGMASOFT® (see Figure 1). The cross-sectional ratios of the individual parts of the runner can be linked via dependencies. Thus, only the position of the cross-sectional reduction in the main runner needs to be varied for the virtual experiments.

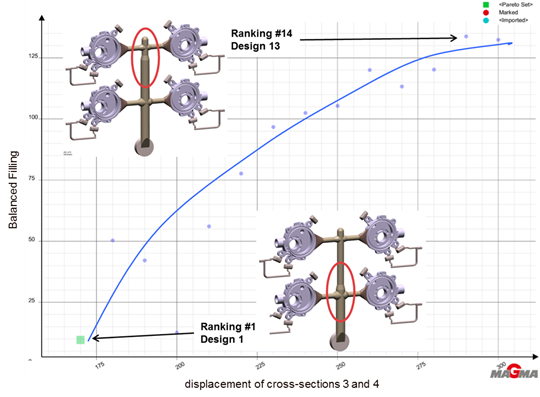

The quality criterion used in MAGMASOFT® for the quantitative evaluation of balanced die filling is called 'Balanced Filling'. The virtual design of experiments is carried out based on a constant shot curve with beginning of acceleration to the 2nd phase starting at 'Chamber full', that is, the waypoint of the acceleration is automatically adjusted to the volume deviations of the shot. The result of the first analyses is shown in Figure 2. The evaluation of the calculated designs shows a clear dependence of the uniform filling of all four cavities on the displacement of the runner sections. The influence of a variable shot curve as well as the interaction of geometry change and shot conditions can be further investigated in another design of experiments (DoE).

If you would like to be able to better evaluate simulation results, we invite you to attend the seminar Evaluation of Simulation Results With MAGMASOFT® with a focus on sand casting/high pressure die casting, which is available as in-house seminar upon request. For more information, please feel free to contact Malaika Heidenreich at +49 241 88901 699 or send an e-mail to academy@magmasoft.de.

This interdisciplinary event is primarily aimed at executives and people in charge from design, quality and purchasing departments who do not use the software for their work on a daily basis, but need simulation results for decision-making.

MAGMAacademy Contact

Dipl.-Ing. Tristan Weidehaus

Malaika Heidenreich

Phone: +49 241 88901-699

Mail: academy@magmasoft.de