Erosion of Core Boxes

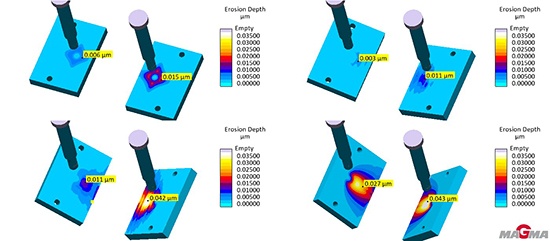

Up to MAGMA C+M version 5.5.0, the erosion of core boxes was calculated as the dimensionless 'Mold Erosion' result. The sand velocity, the sand fraction, the impact angle and the duration of impact were considered, and as a result, a qualitative analysis of the local erosion in the core box was calculated. In MAGMA C+M version 5.5.1, the 'Mold Erosion' result has been replaced by the 'Erosion Depth' result, which shows the erosion depth in micrometers after a shot.

The erosion or material loss of the core box occurs due to the abrasion of the material, which is caused by continuous impact of sand grains under high speed on the core box surface. The extent to which erosion develops mainly depends on the following factors: impact conditions (sand velocity and impact angle), sand properties (density, sand grain shape and sand grain size) and material properties of the mold material (ductility, hardness and density).

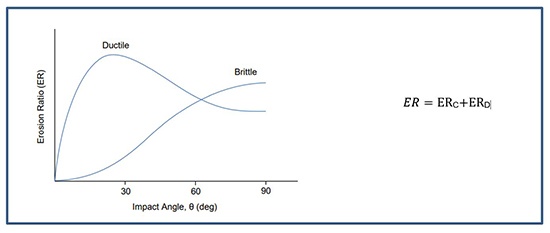

Furthermore, the erosion properties of a ductile material are different from those of a brittle material.

For ductile materials, erosion increases up to the impact angle of about 30°, where the maximum is reached, and then decreases up to the 90° angle.

For brittle materials, erosion increases continuously up to the 90° impact angle, where the maximum is reached.

The 'Erosion Depth' result focuses on the mechanical erosion. Two mechanisms are considered: cutting ( C) and deformation ( D).

Wear by cutting completely displaces or removes a piece of mold material by impact of a sand particle at an angle on the mold surface. Plastic deformation of the mold surface occurs when the kinetic energy of the sand particle is sufficiently high. This process is repeated for subsequent particle impacts until a piece of material is removed from the surface.

Deformation wear is a removal of the mold surface material caused by repeated vertical impact of sand grains on the mold surface. This causes plastic deformation, hardening and cracking of the mold surface until a piece of the material breaks off.

Application in Simulation

A prerequisite for the calculation of the 'Erosion Depth' result in a core shooting simulation is the selection of the mold material with the defined 'C+M Mold Erosion Properties' and the sand material with the defined 'Sharpness Factor'.

In the MAGMA database, there is a default dataset 'X38CrMoV5_Corebox' for steel tools in which the 'C+M Mold Erosion Properties' are defined. If you use other core box materials, please contact our support team.

To all sand datasets, the parameter 'Sharpness Factor' required in each case was added:

- Round sand grains ('Fully-rounded')

- Semi-rounded sand grains (default, 'Semi-rounded')

- Angular sand grains ('Sharp')

Influence of Material and Impact Angle

For an example with the sand H31, which has a "fully rounded" sand grain shape, you can see that the erosion depth for a steel or aluminum mold material increases based on the impact angle. Moreover, you can see that, for an impact angle of 15° to 45°, the erosion depth is about three times higher for the Al mold material used compared to the steel material.

General information

- Venue: Exhibition Dusseldorf

- Date: 12 - 16 June 2023

- Opening times: Daily 10:00 - 18:00 Friday: 10:00 - 16:00

MAGMAacademy Contact

Dipl.-Ing. Tristan Kotthoff

Malaika Heidenreich

Phone: +49 241 88901-699

Mail: academy@magmasoft.de