Flow-optimized design of casting runs

A robust die casting process is the result of various parameters that are coordinated with each other. An important component here is the fluidically optimized design of the runner and gating system in order to create a robust process for error-minimized castings.

When designing the runner system, various requirements have to be considered: At the same time, air inclusions due to flow shadows should be avoided and the melt should be transported to the gate as swirl-free as possible in the runs.

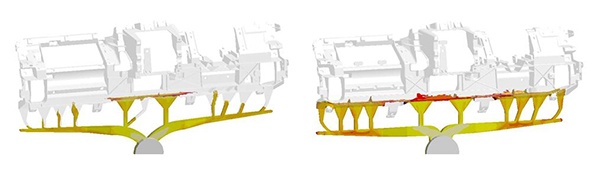

The simulation results allow the evaluation of the flow course. Differently calculated quality criteria allow a quantitative evaluation of error potentials which arise due to a non-optimized flow of the melt in the runner and in the component cavity.

The pictures in the following example show for the runner system of a structural part how the melt is present at the individual gate segments at the same time after changing the position of individual runner segments. This largely prevents the melt from advancing from individual gates into the cavity.

Expand your knowledge about the die casting process in our seminar "Simulation and die casting - Basics, process design, casting system calculation". You will get a complete overview of the individual components of the process, from the determination of the machine size to the gate design. Using concrete examples, the basic flow behaviour for different runner systems will be discussed and the basics for the design of runner systems for robust die casting processes will be imparted.

In the subsequent advanced seminar "Methodical Die Casting", MAGMA experts explain the methodical approach to process analysis. Using concrete industrial examples, they will discuss with you how tool and process design in die casting can also be systematically and sustainably improved in your company.

If you are interested in the seminars, we will be happy to submit a suitable offer. Please call us at +49 241 88 901 99 or send an e-mail to academy@magmasoft.de.

General information

- Venue: Exhibition Dusseldorf

- Date: 12 - 16 June 2023

- Opening times: Daily 10:00 - 18:00 Friday: 10:00 - 16:00

MAGMAacademy Contact

Dipl.-Ing. Tristan Kotthoff

Malaika Heidenreich

Phone: +49 241 88901-699

Mail: academy@magmasoft.de