PŘÍNOSY MAGMA CC 5.5

Co je nového v MAGMA CC?

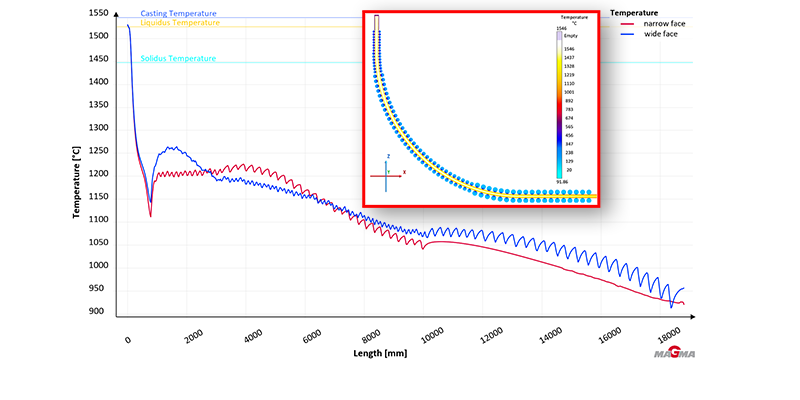

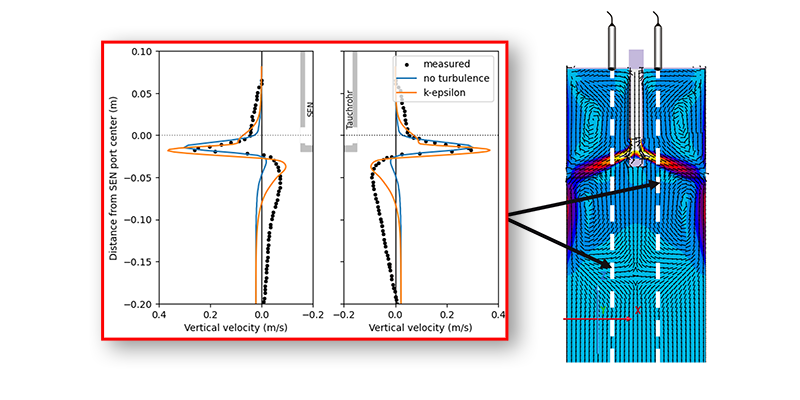

MAGMA CC nabízí významné inovace a vylepšení v oblasti simulace procesů kontinuálního lití. Variabilní řízení rychlosti lití umožňuje flexibilní mapování cyklů „stop & go“, včetně pauz, zpětných zdvihů a cyklických pohybů v procesu tažení. Pokročilý model turbulence přesně popisuje proudění toku taveniny, zejména v dvoufázové oblasti, a usnadňuje analýzu dynamiky proudění při kontinuálním lití.

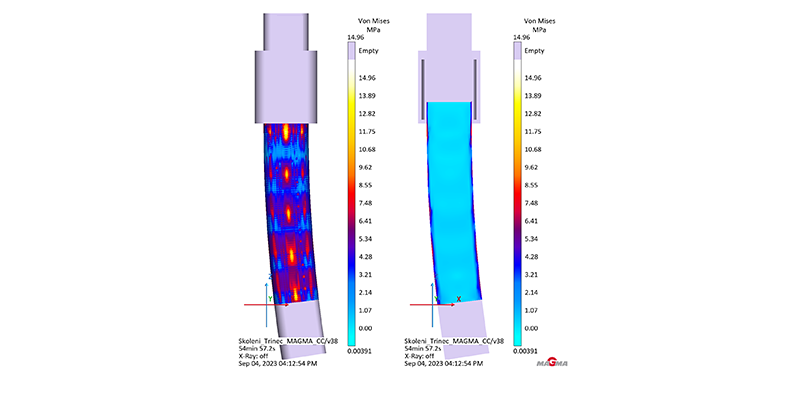

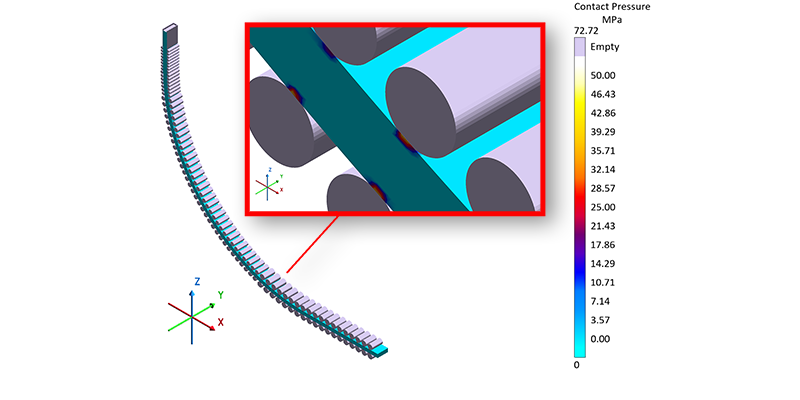

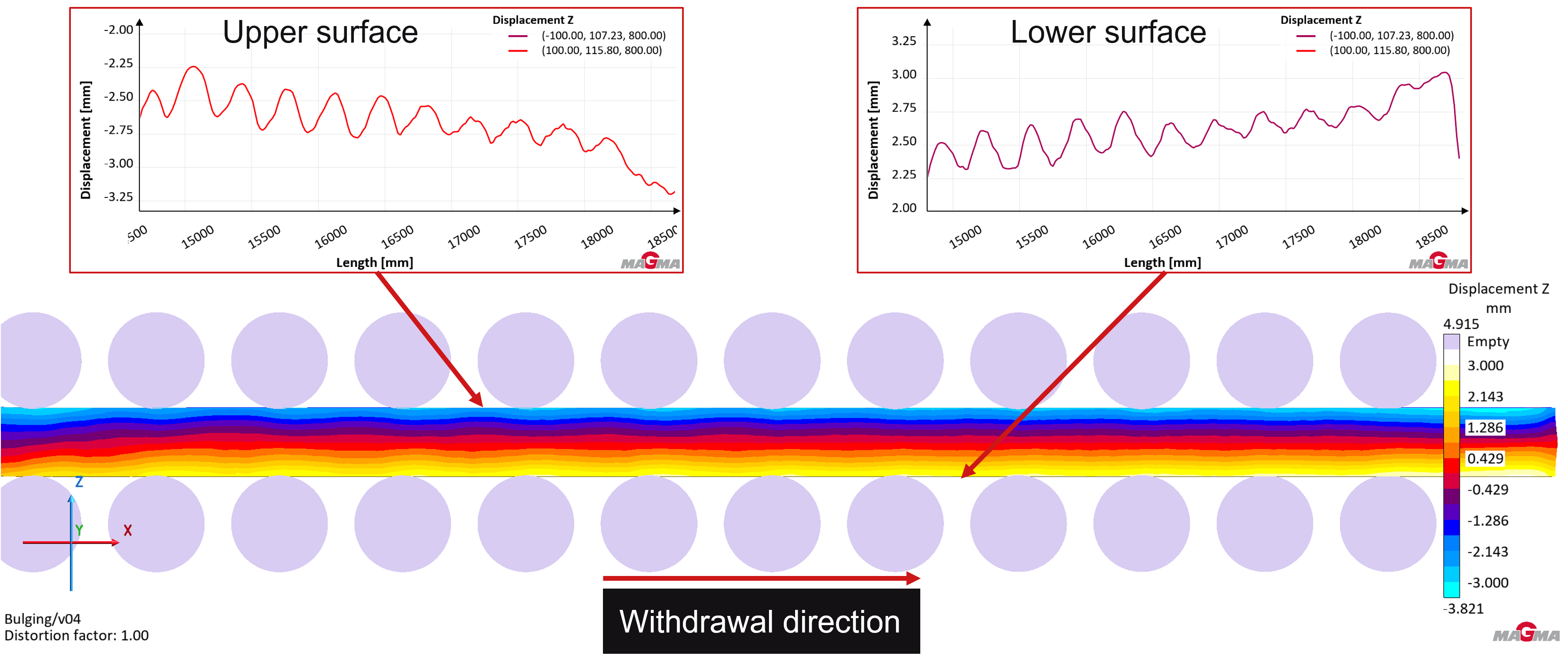

Podrobně lze zkoumat mechanické vlivy, například vlivy způsobené vodicími válci nebo formou. Chyby způsobené polohou válců lze analyzovat a posoudit jejich vliv na deformaci předlitku. To umožňuje určit potenciální příčiny tvarových odchylek předlitku a jejich vliv na jeho kvalitu.

Funkce pro zobrazování částic (tracer particles) navíc umožňuje provádět analýzu distribuce taveniny přes mezipánev do různých předlitků (bram nebo ingotů). Rozšířené funkce MAGMA CC tak poskytují nové kvantitativní informace o kvalitě předlitku v závislosti na procesu kontinuálního lití a pomáhají uživatelům při efektivním vyhodnocování výsledků.

Hlavní přínosy:

- "Stop & go" control: flexibilní změna rychlosti lití, včetně pauz a zpětných zdvihů

- Detailní pohled: rychlé vytvoření výsledků simulace 1D profilu pro celou délku předlitku

- Kvantitativní vyhodnocení vměstků: počítání částic pro posouzení pohybu vměstků v různých předlitcích v průběhu kontinuálního lití

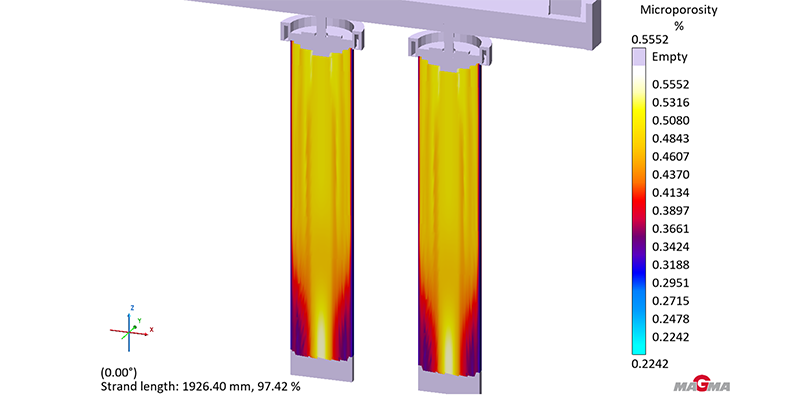

- Mikroporezita: predikce mikroporezity pomocí optimalizovaného kritéria

- Nový model turbulence: přesný popis proudění toku taveniny v mezipánvi, v ponorných vstupních tryskách a zejména v dvoufázové oblasti

- Vliv vodicích válců: analýza mechanického vlivu vodicích válců na deformaci a kvalitu předlitku, zejména v případě nesprávné polohy válců

Nejnovější publikace

MAGMASOFT® 6.1 – Efektivní optimalizace procesů a profitabilita

Díky novým funkcím a mnoha vylepšením nabízí MAGMASOFT® 6.1 rozsáhlou podporu optimalizace procesu nízkotlakého lití a usnadňuje navrhování tlakově litých odlitků. Speciálně vyvinutý procesní modul pro rheocasting a thixomolding nabízí uživatelům řadu nových možností v oblasti výroby jader a kontinuálního lití.

Nová funkce ECONOMICS umožňuje kvantitativní vyhodnocení a optimalizaci nákladů i emisí CO₂ pro všechny simulační projekty, což přispívá ke zvýšení profitability i udržitelnosti všech aplikací.

Systémové požadavky

MAGMASOFT® je vhodný pro všechny stávající operační systémy, jako je Linux, Windows MAGMASOFT® lze použít na počítačích se dvěma či více procesory nebo na masivně paralelních počítačích, clusterech.