Robust and Optimized Virtual Process Chain for Investment Casting

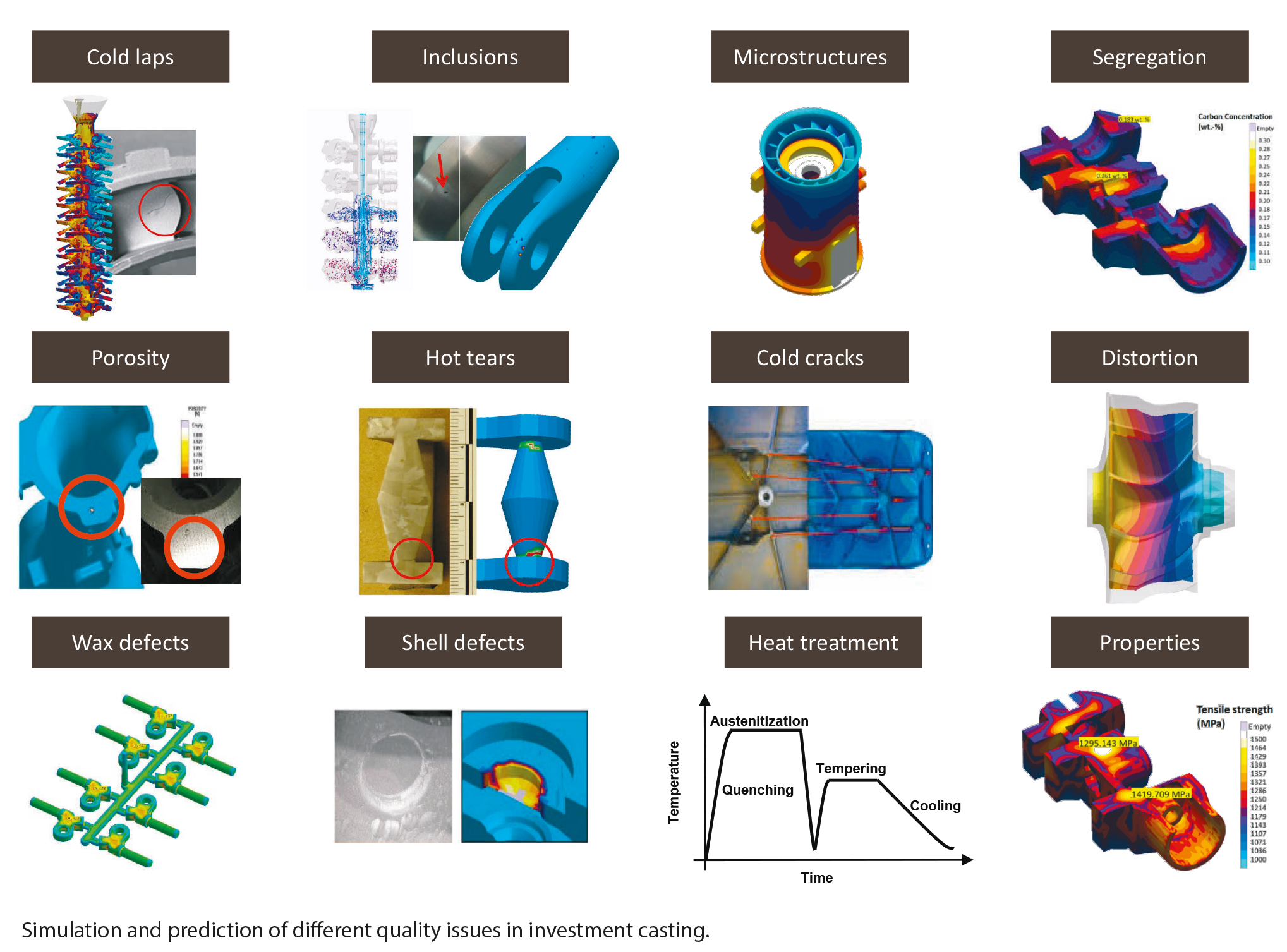

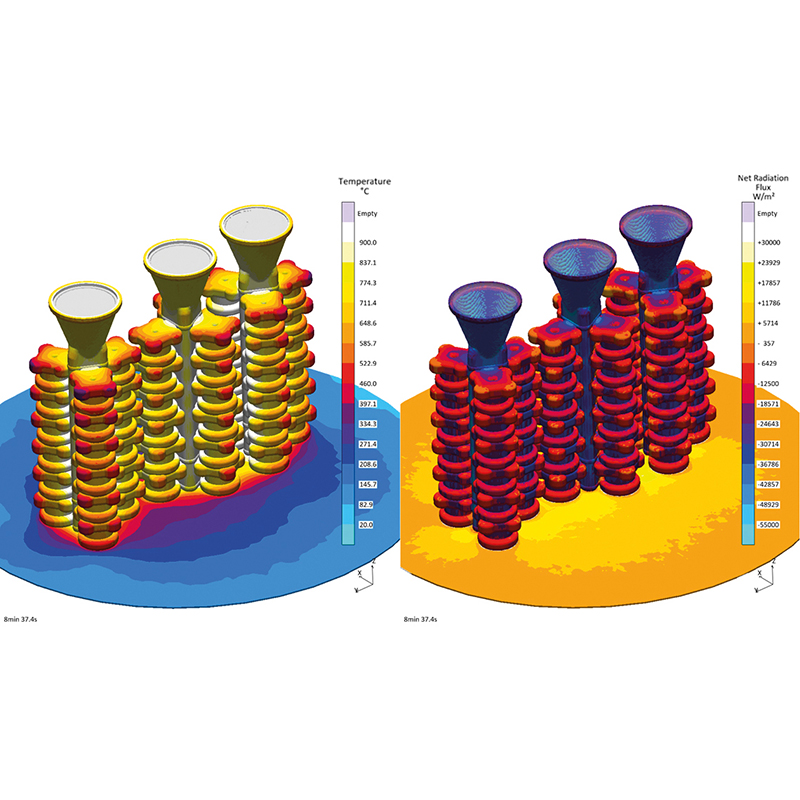

Investment casting has benefited many industries as an economical route to cast near-net-shape metal parts with high geometric complexity and dimensional accuracy. Nonetheless, the manufacturing costs and lead-times during production can quickly limit the competitiveness of investment casting as the preferred manufacturing route. Process simulation is the state-of-the-art tool for eliminating casting trials and improving casting quality, which significantly reduces production costs and time. It allows engineers to assess the technical feasibility of new components and to find the best compromise between casting quality and the production costs before creating costly physical prototypes. Using real industrial applications as examples, this paper will provide an overview of new developments and demonstrate current capabilities of the simulation software MAGMASOFT® in addressing the entire process chain of investment casting virtually. In particular, it will discuss the benefits of Autonomous Engineering to the investment casting process, a new methodology for systematically investigating process windows by means of virtual Design of Experiments or autonomous optimization.

When downloading the PDF, please leave your contact data (you will receive the download link by e-mail) and thus agree to the processing and storage of it by MAGMA casting technology GmbH in Aachen. It will not be passed on to third parties. For further information how we process your personal data, please follow this link Privacy Policy.

The complete publication is available in the linked PDF

Robust and Optimized Virtual Process Chain for Investment Casting