New Markets for Casting

During recent years, the market for wind power has grown by orders of magnitude and has created a completely new sector for casting applications. Many of the components cast in this area today did not exist at all ten years ago or were created to substitute welded or forged parts. Due to the continuing demand for continuously growing wind turbine sizes, many of the existing cast components have to be completely redesigned to meet the required specifications for performance and weight.

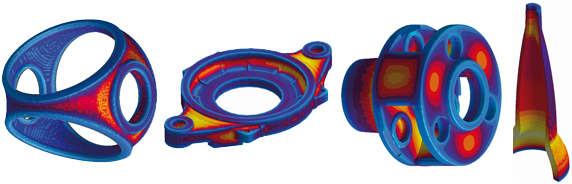

Since most of the parts are ductile iron components, metallurgy and robust process conditions are crucial for reliable component behavior. Hence, casting simulation today is a mandatory tool to guarantee the required properties and process during the component design stage.