Martinrea Honsel uses MAGMASOFT® from quotation to start

Casting Process Simulation as a Strategic Tool

Many liters of molten aluminum flow into the shot chamber of the living-room sized die casting machine. The plunger pushes the melt into the runner in order to shoot it into the mold within a few milliseconds. After a short cooling period in which the melt solidifies, the die opens, and the gripping arm lifts an entire engine block out of the machine.

The die casting machine operates in one of the many buildings on the premises of Martinrea Honsel Germany GmbH in Meschede. The light metal foundry, with 580 million Euro in sales, is one of the large automotive suppliers in Germany. It produces engine blocks, transmission components, cylinder heads and other light metal parts for virtually all important automotive manufacturers - Audi, BMW, Jaguar, Mercedes, Volvo, etc. In addition to Germany, Martinrea Honsel has production sites in Brazil, Mexico and Spain.

Process Control through Casting Process Simulation

Martinrea Honsel, formerly Honsel AG, has become successful as a jobbing foundry that has mastered its production processes in such a way that they can be smoothly synchronized with the target industries and at the same time deliver products of the high quality that automotive manufacturers demand from their suppliers. However, Martinrea Honsel is more than just a mere production service provider. Often, their foundry engineers also engage in the development of cast parts.

One of the major tools for process control and the achievement of high quality standards at Martinrea Honsel is casting simulation. The foundry has been using the software MAGMASOFT® from the market and technology leader MAGMA, located in Aachen, Germany, since 1999. Casting process simulation reveals what happens from the time when the melt enters the die until the finished casting is removed. This allows for the analysis and elimination of potential error sources in the process. Simulation, however, is not just used for optimal design of the casting process but also in the development of the cast part itself.

Early Simulation offers Degrees of Freedom

"Even more than customers who have a finished design that should be cast, we prefer those who come to us with just a basic concept," explains Hans-Jürgen Spychala, manager of die casting design. "Then, we can deploy casting process simulation up-front at the design stage and construct the geometry in such a way that it can be produced easily and economically." The casting and the die including the runners, ingates, overflows and other necessary parts of the casting system, as well as the process control parameters, can then be developed to perfectly fit together.

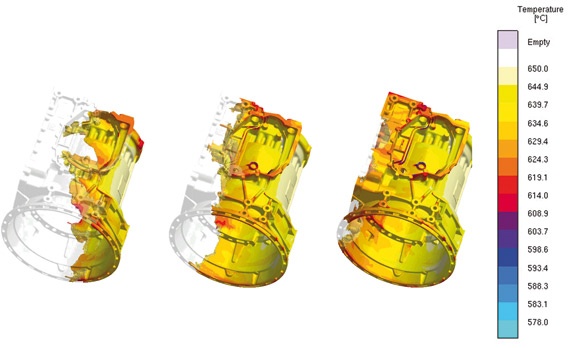

Engineers use filling simulation to analyze the turbulent entry of the melt into the die. It shows when and/or where air or gas entrapment occurs in the melt that could lead to oxidation and porosity, or if solidifying melt block the flow too quickly so that the mold cannot be filled completely. Solidification simulation illustrates how the casting solidifies, where porosity – small defects in the casting – may form due to shrinkage effects and how the microstructure of the casting develops.

To evaluate the simulation results, mold filling and solidification are displayed as color-coded graphics or movies, each indicating the course of a parameter such as temperature or flow velocities. This allows trained users to interpret the results intuitively.

Porosity and microstructure have a significant impact on the quality of a casting, which are reflected in its mechanical properties, durability and workability, such as weldability. With casting process simulation, the development team of Martinrea Honsel can recognize – even without a single “real casting experiment” – whether or not a casting can be produced with the given die and with the desired properties.

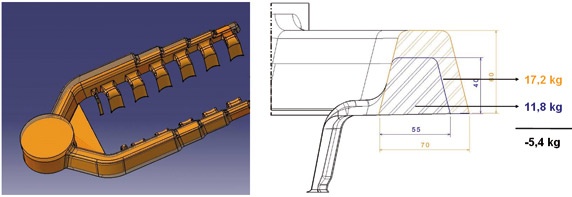

If casting process simulation is used up-front in casting design, the engineers have certain degrees of freedom to optimize the process and the casting with regard to an optimal final product. Strongly varying wall thicknesses or material accumulations, for example, that could lead to lower casting quality can still be corrected in the design. Moreover, simulation can point out constructional alternatives, such as whether a fastening hole can be cast directly into the part instead of being drilled afterwards.

Simulate Optimal Processes - From Design to Start of Production

If a customer consults Martinrea Honsel with a finished casting design, casting process simulation helps to quickly and safely determine the correct process control parameters: the casting injection pressure, shot curve, ingate cross-sections and velocities, venting of mold cavities, pouring temperature and other parameters that define the filling processes, can be examined and decided upon using simulation.

In addition, casting process simulation provides critical design information for patternmaking and the entire production layout. Again, different approaches can be tried and checked by the software in order to gradually approach the ideal overall casting system.

"A casting process is simulated between 5 and 12 times in a typical project, starting with quotation and patternmaking to production start", explains Hans-Jürgen Spychala.

Customers demand Standard Software for Casting Process Simulation

Since 1999, Martinrea Honsel has been using casting process simulation internally, relying on MAGMASOFT® from MAGMA GmbH, Aachen, Germany. In the 1980s, company founder Dr. Erwin Flender and MAGMA employees developed and advanced simulation methods at the University of Technology, RWTH Aachen. With the establishment of MAGMA, they were the first ones to bring casting process simulation for productive practice to market maturity. To date, MAGMA has secured and constantly expanded its position as technology leader with the highest investments in research and development.

"There were and are a series of properties that justify the position of MAGMASOFT® – quality of simulation, speed, automatic meshing, ease of use, etc. However even more important for the decision to use MAGMA was that our customers were already using it and that it constitutes more or less a standard for casting process simulation – at least in the automotive industry," recalls Hans-Jürgen Spychala. "If somebody supplies a MAGMASOFT® simulation result, it is widely accepted as reliable.

In-House Simulation Creates and Multiplies Expertise

Even before 1999, simulation was used at Martinrea Honsel. Until then however, the foundry used simulation as an engineering service. The increasing relevance of methods for process control led to the strategic decision to implement the software throughout the enterprise. "We wanted to run the projects in-house with our own people in order to learn from each simulation, to accumulate and reuse the expertise," explained the design manager in justifying the company's decision. “It is important who prepares and analyzes a simulation project. With external simulations, you never know who conducts them and whether they have the right skills and experience."

Potential for Optimization of Casting Process Simulation

Though it has been many years since the 'pre-simulation' times, they are still remembered: "A project used to take about half a year or longer from start of sampling to die release. Today this time has been halved." With simulation, complex casting experiments that used to be conducted to determine the right combination of parameters and casting layout have now become a task for the software, which accelerates the process enormously and makes it cheaper. That's why it often turns out that after first sampling, the casting nearly corresponds to the specifications and the parts can be used for bench testing.

"Apart from that, we could make the entire production more economical through simulation: process cycle times could be shortened and scrap could be reduced," adds Hans-Jürgen Spychala. Some changes also occurred in casting simulation communication: "Simulation results now serve as a basis for discussion for a team comprising quality assurance, production and engineering. Previously, such discussions lacked a solid basis."

Simulation Gets Strategic

Today, casting process simulation belongs to the most important strategic tools at Martinrea Honsel and has become indispensable in daily business. Not only because customers want it, but also because the competitive situation and the necessity for an economic production with reliable quality demand it.

To the website of Martinrea Honsel Germany GmbH