Reduction of surface defects through optimized gating design

For thin-walled castings, it is challenging to ensure a mold filling that is as smooth as possible with low turbulence, yet still filling the cavity with sufficient speed. This is the only way to avoid flow-related defects and cold laps. This requires a gating that controls both the flow rate of the melt as well as the temperature loss during mold filling.

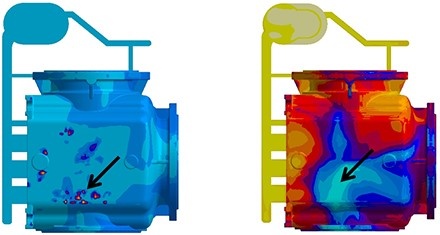

The following example shows air entrapment in conjunction with cold laps in the upper area of the castings during the production of a pump housing manufactured using GJL-200. The simulation of the actual condition showed air entrapments and a relatively cold melt (below liquidus temperature) in the critical areas (see Figure 1).

Principally, air trapped in the melt can vent through the mold material into the upper area of a casting. To achieve this, the permeability of the mold material as well as the local differences in pressure are factors in the simulation. However, this requires that there is the necessary time for the venting. In other words: The melting temperature must be high enough when reaching these areas. Otherwise, the immediate solidification prevents the entrapped air from venting fast enough through the mold material.

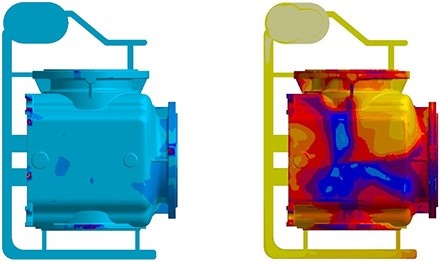

The casting design was optimized systematically by differently arranging the runner and the gates and varying them with an exchange of geometry. As a result, the flow of the melt was stabilized and the air entrapment in the upper area of the casting was reduced significantly.

Moreover, the temperature loss during mold filling was successfully minimized, thus significantly reducing the risk of cold lap (see Fig. 2). The combination of both effects resulted in sound castings with a clean surface.

Are you interested in discovering more about the influences of various manufacturing parameters and a simulation-based, methodical design of casting systems and manufacturing conditions? Then attend the workshop "Coaching Optimization" at MAGMAacademy. Please contact academy@magmasoft.de for a workshop in English language.

We look forward to receiving your application under jobs@magmasoft.de!

If you are applying by post, please send your application to the following address:

MAGMA GmbH

Kackertstr. 16-18

52072 Aachen

Germany