Economical and High-Quality Die Casting Through Intelligent, Efficient Temperature Control

he optimization of cycle times, mold service life, microstructures and distortion of the castings under the required specifications for component quality and process economy is daily practice. In this context, the layout and case-specific optimization of mold temperature control are of outstanding importance. For this task, product and process developers today have modern mold manufacturing processes and virtual optimization tools at their disposal which, when used from the idea to the series production of a component, enable high added value.

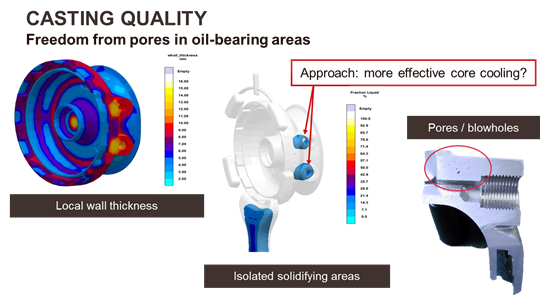

A hydraulic component serves as an example here, which by design involves material accumulations and thus risks of solidification porosity: a classic in aluminum die casting! It was examined with which additional cooling measures in the mold these risks can be minimized. This involved the comprehensive testing of the small given degrees of freedom.

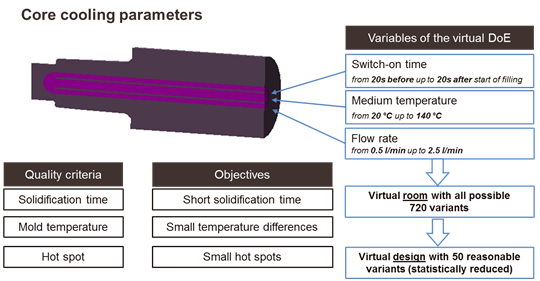

In the approach chosen here, it was possible to increase the cooling of the contour cores in the hydraulic connections without negative effects in other areas. With the aid of the simulation, practically all conceivable cooling variants were calculated in a very short time and evaluated in terms of their effects on the casting and the process in a "virtual test plan".

The statistical evaluation capabilities of virtual DoE make it possible to determine at a glance how sensitive the casting and process are to the different cooling parameters and to determine the best compromise depending on the weighting of the objectives.

Further potential for efficient temperature control in die casting is provided by three-dimensional, contour-matched temperature control systems such as can be produced by generic AM processes. They have been state of the art in polymer injection molding for years and are slowly gaining attention in die casting.

Conclusion: Temperature control systems close to the component and "thermally nimble" molds make casting processes controllable, more robust and more cost-effective in the sense of a Foundry 4.0 approach.

If you want to learn more about the enormous potential of intelligent temperature control of die casting molds, then attend the FORUM "Process and Component Optimization through Efficient Mold Temperature Control" (May 19-20, 2021) initiated by voestalpine High Performance Metals and MAGMA, held in German language.

General information

- Venue: Exhibition Dusseldorf

- Date: 12 - 16 June 2023

- Opening times: Daily 10:00 - 18:00 Friday: 10:00 - 16:00

MAGMAacademy Contact

Dipl.-Ing. Tristan Kotthoff

Malaika Heidenreich

Phone: +49 241 88901-699

Mail: academy@magmasoft.de