MAGMASOFT® as a Management Tool Focus on Profitability and Quality

Today, casting process simulation offers a virtual test bed for carrying out casting trials with nearly unlimited degrees of freedom and without any significant economic or production risks. During the development of the “E-Traction” electric motor housing for the VW Golf, Volkswagen AG decided to systematically use MAGMASOFT® for the design and an early-stage confirmation of a highly robust product and production process.

The Volkswagen AG team, consisting of experts from development, design, production and tooling, applied MAGMASOFT® in the “classical” way, using the simulation of filling and solidification to analyze the effectiveness of different changes made step by step. Due to the stringent technical requirements for the casting and the extremely limited time available, the aim was to virtually assess all relevant risks and to demonstrably minimize and, ideally, eliminate them prior to the design freeze of the casting and die.

From Classical Optimization to Virtual Design of Experiments

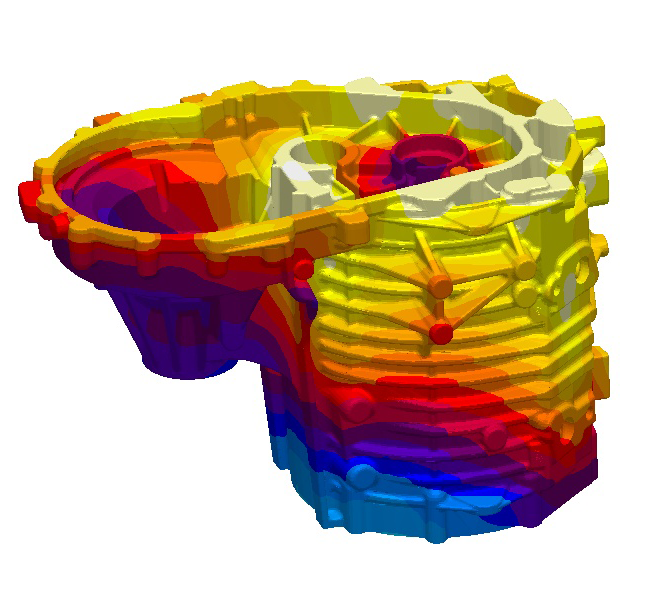

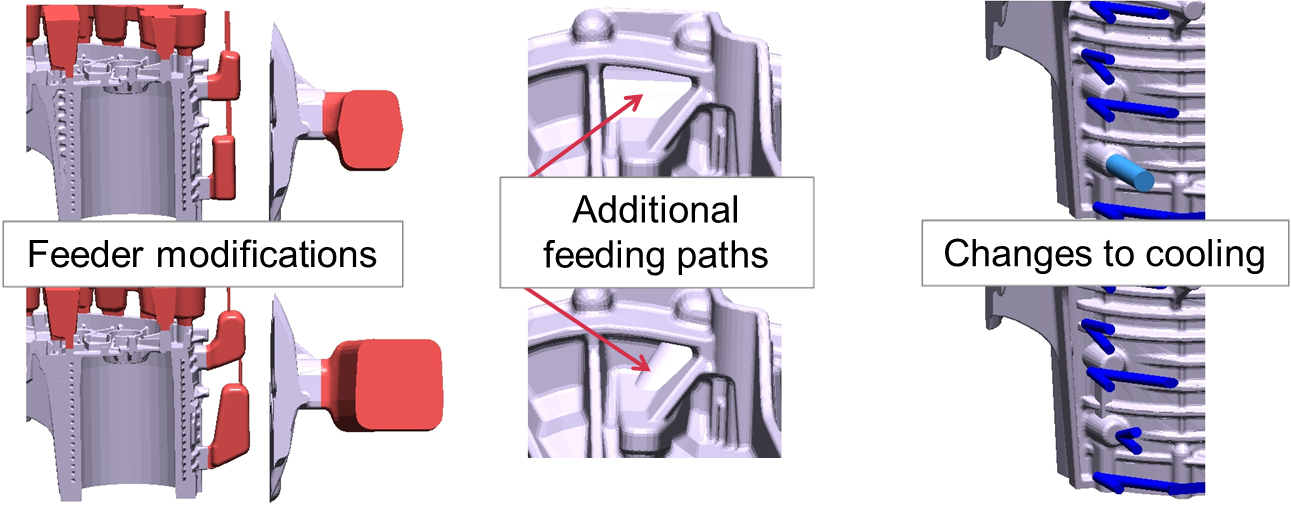

Based on the solidification path of the electric motor housing, the engineers at Volkswagen iteratively used

MAGMASOFT® to make changes to optimize the casting layout. For this purpose, the team systematically analyzed measures for improved filling through gating system modifications, as well as investigated changes to the feeder sizes and positions for optimized solidification. In addition, the influence of integrating additional feed paths into the casting geometry and improving the temperature control in the die on the casting quality was evaluated.

Changes leading to improvements were adopted for the next iteration, whereas ineffective changes were discarded. In 19 steps, the engineers arrived at a version complying with the high quality criteria, which was then used as a basis for cutting the tooling and was successfully put into production.

Methodological Preparation and Statistical Evaluation

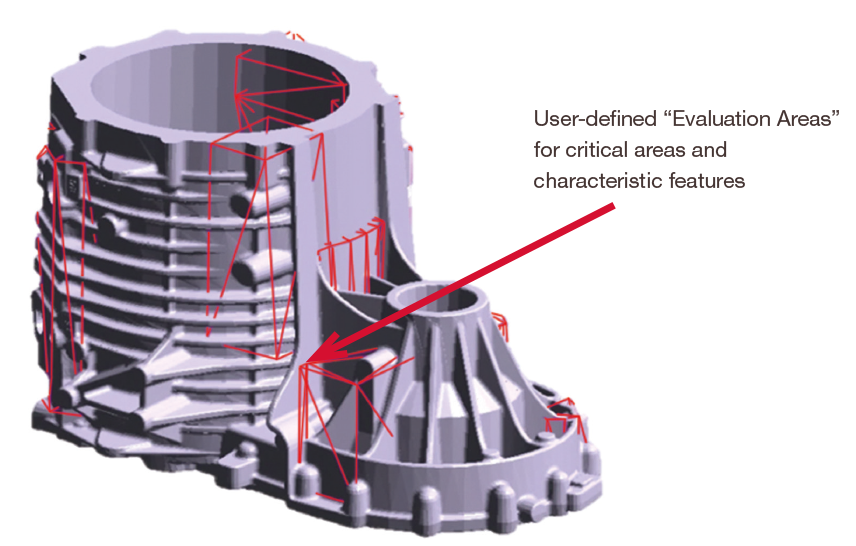

The use of evaluation areas, which can be defined in the casting by the user in MAGMASOFT®, helps to focus on critical functional areas in the casting or tooling. This methodological approach ensures a consistent evaluation of potential areas of risk over the complete duration of the project, from the first conceptual design to the approved process setup. By continuously visualizing and pursuing different quality criteria for all critical areas of the casting, it is possible to easily evaluate the effect of a given change on the project success.

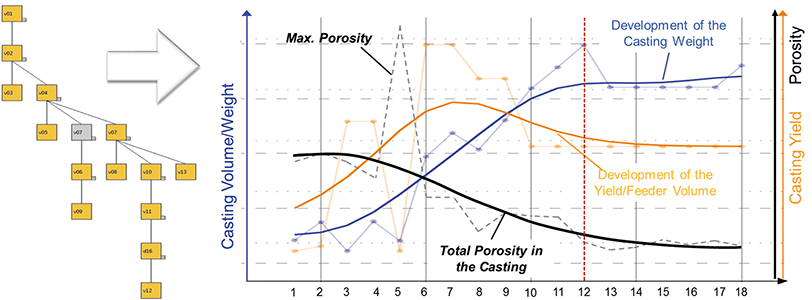

During the development of a complex casting such as the “E-Traction” housing, one can easily lose track of where one stands when performing a classical iterative simulation analysis. When adopting a step-to-step approach, it is natural to focus solely on individual, critical areas or issues. Thus, it is not easy to say how the selected modifications affect other areas of the casting. In retrospect, it is often not possible to find concrete answers to questions such as: “Which insights were gained from version 2?” or “What were the real results of the changes made in version 8 and which effect did they have on the costs?” Revisiting such questions after the fact often tends to be a tedious task. In the present case, the engineers at Volkswagen AG used MAGMASOFT® to be able to evaluate and follow the effectiveness and profitability of the improvements achieved through the numerous changes throughout the complete project.

The MAGMASOFT® Assessment Perspective allows the user-defined combination of results from individual simulation runs, virtual designs of experiments or autonomous optimizations. These results may come from one or several development projects, and they can be compared based on different criteria in a straightforward manner. Thanks to the use of statistical methods, the quantitative comparison of all imported project alternatives yields robust results without any subjective influence. With this tool, solutions and suitable options can be quickly and easily identified and evaluated. These possibilities are particularly useful not only for identifying relevant quality criteria, but also as a basis for economic decisions in project management.

This allowed an early and continuous visualization of the progress of the “E-Traction” motor housing project, leading to an optimal compromise between quality, material usage and profitability. The expected change in production costs due to the reduced feeder volume and improved yield, resulting from cooling modifications in the die, could be clearly seen starting from version 12 (figure below).

Successful Project Management

Using the capabilities of MAGMASOFT® as a project management tool thus enables efficient and fast actions. Knowledge gained from the virtual evaluation of the casting process forms a firm basis for secure decision-making and effective early-stage optimization measures.

The methodological implementation of Autonomous Engineering with MAGMASOFT®, combined with the consequent use of the MAGMA APPROACH in the development process, provides Volkswagen AG with systematic information about correlations between production parameters and quality criteria for a casting. Thanks to this “frontloading”, risks can be identified in time or even be prevented. The digital casting process is synonymous with economic quality – right from the start.