Co je nového v MAGMAlpdc včetně CPC & MAGMAwheel?

Co je nového v MAGMAlpdc & MAGMAwheel?

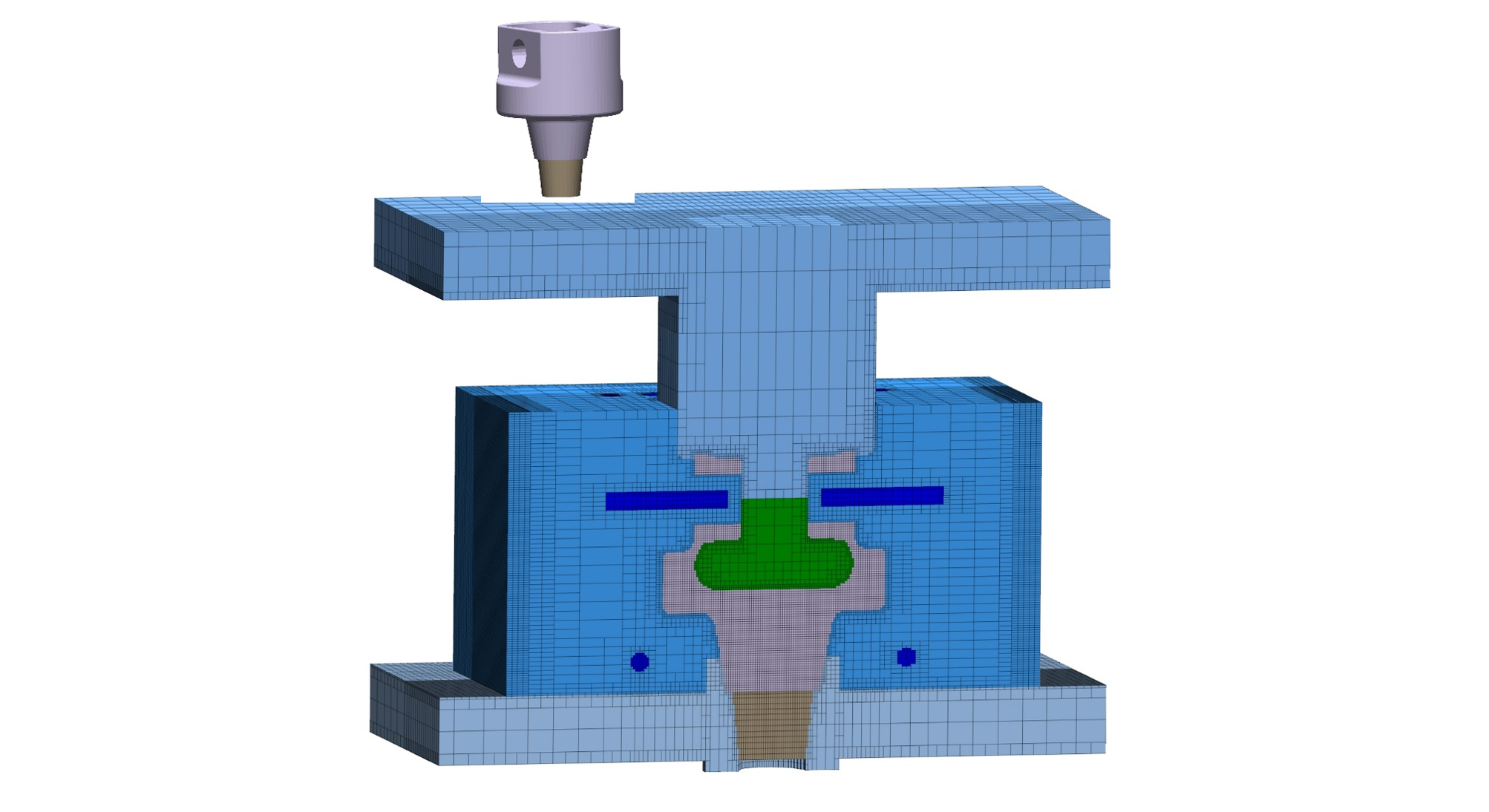

MAGMASOFT® 6.1 přináší uživatelům rozsáhlé změny v oblasti simulace procesů nízkotlakého lití. Integrovaný nový solver a optimalizace generování sítí pomocí kompozitních a TAG sítí (True Adaptive Geometry Meshes), které se již osvědčily při výrobě jader, vysokotlakém lití a lití do trvalých forem, umožňují přesnější a efektivnější zobrazení složitých slévárenskýchch procesů.

Nová funkce 'Heat-up Phase' umožňuje předehřev trvalých forem pomocí elektrických topných patron s PI regulací a regulací teploty Variotherm.

Nové výsledky „Tracer“ poskytují navíc detailnější analýzu teploty, rychlosti, tlaku a délky dráhy taveniny. Výsledky „Air“ rovněž usnadňují identifikaci a vyhodnocení zahlceného vzduchu v odlitku.

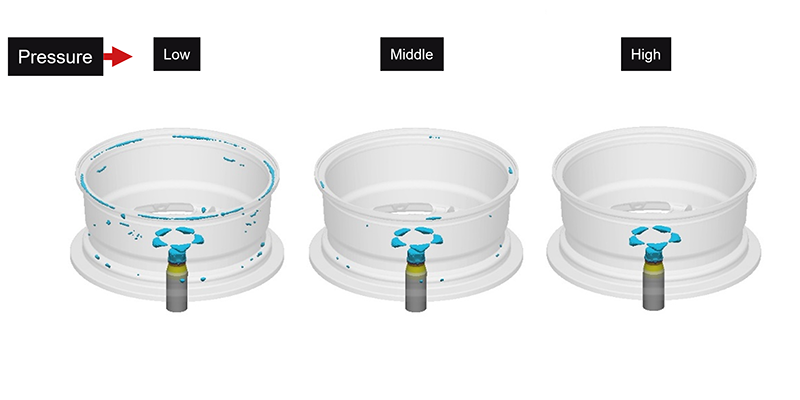

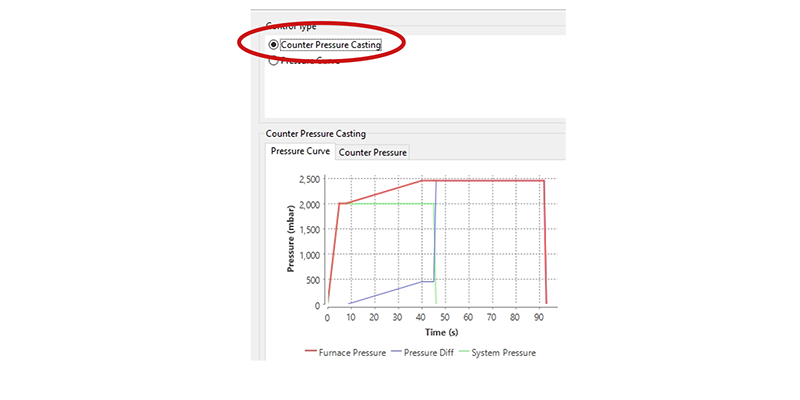

Pro odlévání s protitlakem (CPC) je nyní k dispozici vylepšení, které poskytne přesnou definici a simulaci procesních parametrů, jako je protitlak a rozdíl tlaků. Což zlepší podrobnou analýzu vlivu na dosazování i mechanické vlastnosti.

Hlavní přínosy:

- Nové technologie solveru: Pro přesné a efektivní mapování složitých procesů odlévání jsou použity solvery, které se již osvědčily při vysokotlakém odlévání, lití do trvalých forem i při výrobě pískových jader.

- Rozšířená tvorba sítí: integrace kompozitních sítí a sítí TAG (True Adaptive Geometry) pro přesné zobrazení geometrie a slévárenských procesů

- Fáze ohřevu: ohřev trvalých forem pomocí elektrických topných patron s PI regulací a regulací teploty Variotherm

- Výsledky „Tracer“: detailní analýza teploty, rychlosti, tlaku taveniny, ale i délky dráhy

- Identifikace zahlceného vzduchu: Nové výsledky „air“ zlepšují vyhodnocení zahlceného vzduchu v odlitku.

- Speciální rozšíření CPC: specifická definice procesních parametrů a simulace odlévání s protitlakem

- MAGMAlpdc a MAGMAwheel: inovace zohledňující povrchové napětí, vliv tlaku na dosazování, proudění v teplotně regulovaných kanálech a elektrických tepelných systémech

- Rozšířené možnosti predikce: analýza turbulence, zahlcený vzduch, porezita související s dosazováním a lokální tepelné toky

Nejnovější publikace

MAGMASOFT® 6.1 – Efektivní optimalizace procesů a profitabilita

Díky novým funkcím a mnoha vylepšením nabízí MAGMASOFT® 6.1 rozsáhlou podporu optimalizace procesu nízkotlakého lití a usnadňuje navrhování tlakově litých odlitků. Speciálně vyvinutý procesní modul pro rheocasting a thixomolding nabízí uživatelům řadu nových možností v oblasti výroby jader a kontinuálního lití.

Nová funkce ECONOMICS umožňuje kvantitativní vyhodnocení a optimalizaci nákladů i emisí CO₂ pro všechny simulační projekty, což přispívá ke zvýšení profitability i udržitelnosti všech aplikací.

Systémové požadavky

MAGMASOFT® je vhodný pro všechny stávající operační systémy, jako je Linux, Windows MAGMASOFT® lze použít na počítačích se dvěma či více procesory nebo na masivně paralelních počítačích, clusterech.