MAGMA představuje MAGMASOFT ® 6.1: Efektivní a udržitelné slévárenské procesy

Německá společnost MAGMA představuje novou verzi svého softwaru MAGMASOFT ® 6.1 pro simulaci slévárenských procesů. Nové funkce a vylepšení umožňují optimalizaci nízkotlakého lití a zjednodušují návrh tlakově litých odlitků. Speciálně vyvinutý modul je zaměřen na procesy rheocasting a thixomolding. Široká škála možností pro oblast výroby jader a kontinuálního lití umožňuje uživatelům navrhovat procesní sekvence přesně a efektivně.

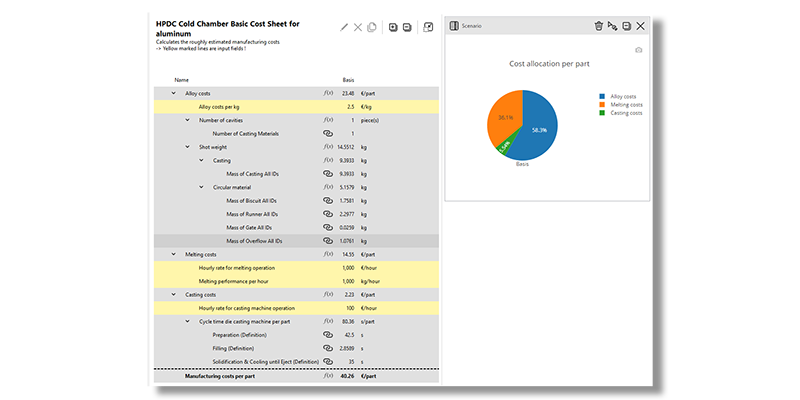

Nová, plně integrovaná perspektiva ECONOMICS umožňuje uživatelům kvantitativně vyhodnotit náklady a emise CO₂ na základě definovaných údajů, a podpořit tak udržitelnost a efektivnost slévárenských procesů.

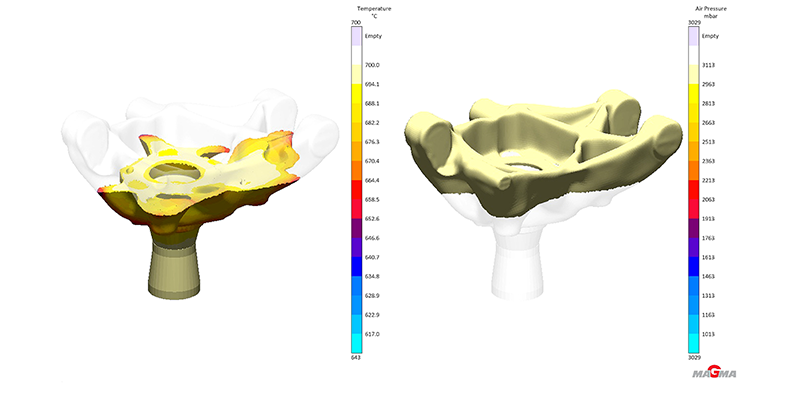

LPDC: Optimalizace se software MAGMASOFT® 6.1

Pokročilá technologie solveru a dokonalejší generování sítí umožňují efektivnější zobrazení složitých procesů odlévání. Nová funkce 'Heat-up Phase' umožňuje předehřev trvalých forem pomocí elektrických topných patron s PI regulací a regulací teploty Variotherm. Additional results and criteria support the analysis of both filling and solidification processes.

For counter-pressure casting, a dedicated extension is now available, taking into account both the optimization and the influence of process parameters, such as counter-pressure and pressure difference, on feeding and mechanical properties.

MAGMA ECONOMICS: Sustainable Production

MAGMA ECONOMICS is a new, fully integrated perspective of MAGMASOFT® that uses the capabilities of "Autonomous Engineering" for optimization and virtual design of experiments. ECONOMICS allows users to quantitatively evaluate costs and CO₂ emissions directly in the software and along the entire casting process – based on existing data. With customizable templates for common materials and processes, MAGMA ECONOMICS can compare scenarios without requiring additional simulation time, supporting informed decisions that simultaneously consider technical, economic and ecological goals.

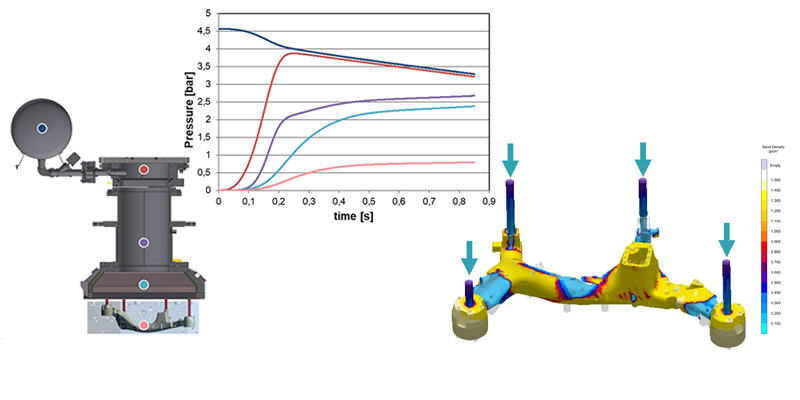

Core Production: Extended Simulation Capabilities

MAGMA C+M (core production) automatically calculates the pressure applied to the shooting nozzles based on the machine parameters, enabling a realistic mapping of the overall system of machine, core box and shooting process. The calculated pressure curves integrate seamlessly into simulations and virtual design of experiments. The simulation time for gassing processes using inorganic binders has been significantly reduced. MAGMA C+M is now even more closely linked to the current machine configuration and provides robust, practical information for the real situation in the core-making shop.

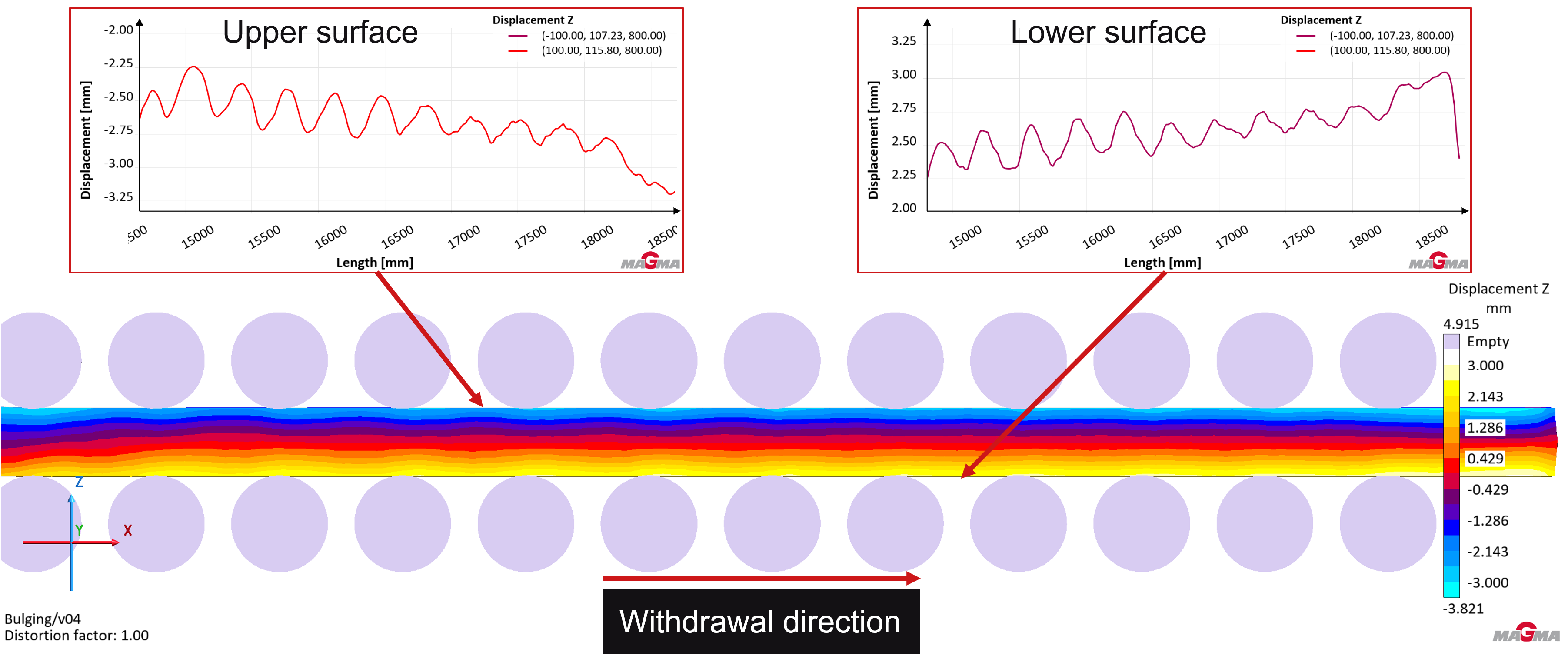

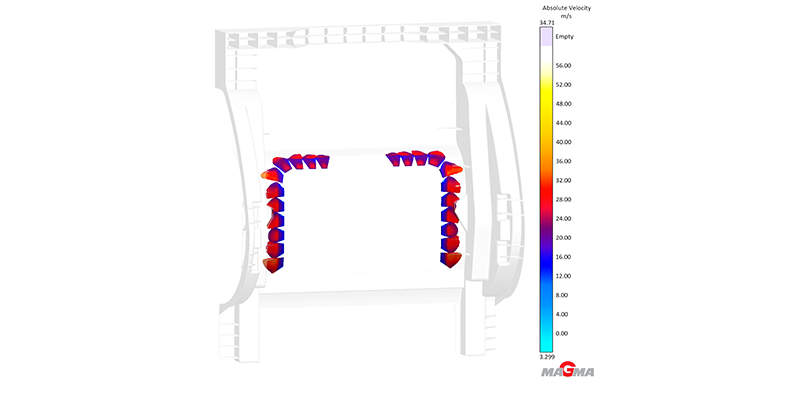

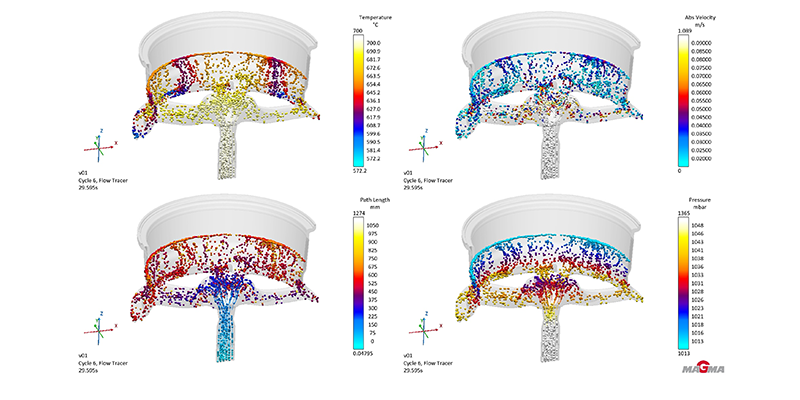

Optimization in continuous casting: MAGMA CC

The variable control of the pouring velocity in MAGMA CC (continuous casting) allows a flexible mapping of "stop & go" cycles. Mechanical influences of guide rollers on the strand deformation are also taken into account. The tracking of tracer particles makes it possible to analyze how melt is distributed across different strands via launders. The extended capabilities of MAGMA CC provide new quantitative information on process-dependent strand quality and support users in the efficient evaluation of results.

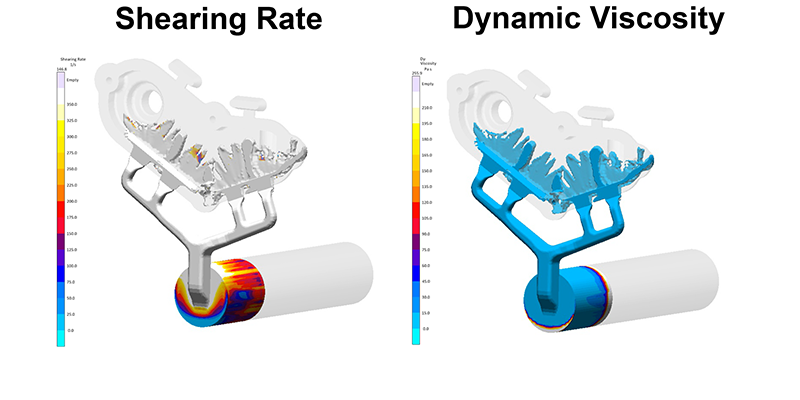

MAGMAsemisolid: Innovation in Lightweight Design

The new process module MAGMAsemisolid uses a special viscosity model to take into account the specific conditions and thixotropic rheology of semi-liquid metallic melts in rheocasting and thixomolding processes. As a fully integrated, powerful tool, it helps to create process transparency and make optimum use of the potential of these manufacturing technologies.

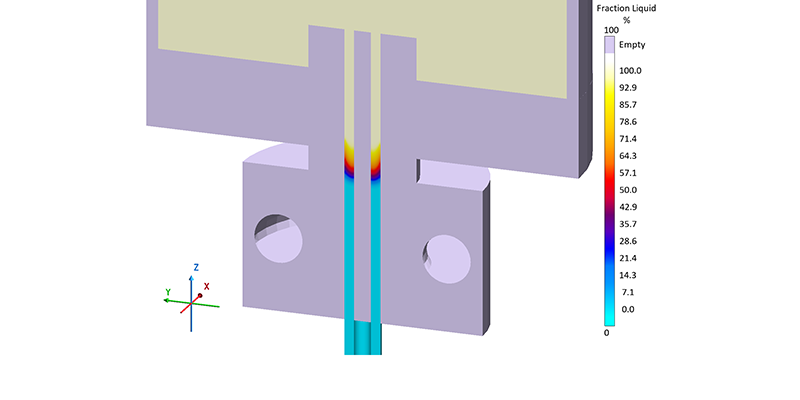

MAGMAhpdc: Optimized Component Design in High Pressure Die Casting

MAGMAhpdc facilitates the early design of castings, even before the machine or casting system has been determined. The new "Virtual Gate" function allows positioning multiple inlets directly on the casting, while flexible casting conditions enable a quick initial assessment of the die filling process.

Additional Innovations for Increased Efficiency in All Casting Processes

MAGMASOFT® 6.1 provides advanced tools for the simulation, analysis and optimization of casting processes. The most important innovations include:

- Expanded material databases: New products have been added to the FOSECO Pro module, which now features Çukurova feeder datasets for the first time.

- New measurement mode for MAGMAstress: Distance, flatness and roundness are measured directly during the evaluation, facilitating the evaluation of casting distortions.

- 'Tracer count': Particles in the melt are counted in predefined areas.

- 'Channel Assistant': Cooling channels are automatically generated from existing voids in the mold geometry.

- Automatic export for MAGMAinteract®: Project results and STL geometries are automatically exported as MAGMAinteract® files, which reduces manual effort.

With these enhancements, MAGMA underlines its commitment to casting excellence: MAGMASOFT® 6.1 significantly expands the capabilities of casting process simulation and supports customers in optimizing their manufacturing processes in a targeted manner – with greater efficiency, precision and sustainability.

Tisková služba

Pro získání základních informací nebo obrazových materiálů prosím kontaktujte MAGMA:

PR a marketing

press@magmasoft.de

Telefon: +49 241 88901 0