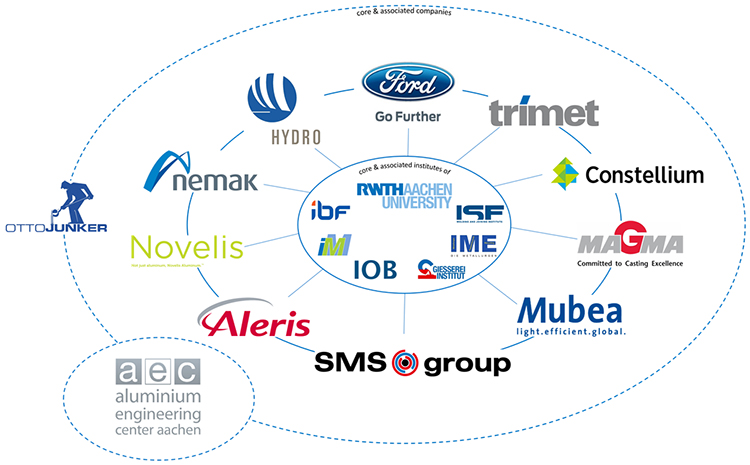

Since 2013, a group of ten industrial partners, including MAGMA, and four institutes from the RWTH Aachen University made a commitment to join forces in the open-innovation cluster AMAP, which stands for "Advanced Metals and Processes".

The objectives of the AMAP cluster are research, development, education and training in the areas of the metal production, processing of metals and the manufacturing of products using metallic materials. The cluster implements the novel idea of bringing both industry and university researchers from diverse areas together at a single location in Aachen, to perform joint research and development activities.

Current projects in the areas of rolling, forging, casting, melt cleanliness and recycling have been defined. Starting from January 2013, approximately 30 engineers and researchers from the various partners work jointly on these topics within the cluster in shared office facilities in Aachen. The cooperation is initially focused on aluminum-based materials.

MAGMA was involved since the beginning in the AMAP P6 project “Hot Distortion of Sand Cores during Casting”. The objectives of this project were to gain a fundamental understanding of the distortion of sand cores and the most important factors which influence this distortion; casting process simulation was used to predict core distortion in order to optimize the dimensional accuracy of cast components and minimize unavoidable distortion in the construction phase of core boxes in advance.

Partners of this project were the companies Nemak and MAGMA together with the Foundry Institute of the RWTH Aachen University.

Currently MAGMA is partner in two running AMPA projects.

AMAP P9: Property Prediction after Heat Treatment

The project goals in this project are the prediction of local mechanical properties after heat treatment for aluminum shape castings. The project focuses on the property changes after solution heat treatment and during artificial ageing.

Partners involved are the companies Nemak and MAGMA together with the Institute of Physical Metallurgy and Metal Physics of the RWTH Aachen University.

AMAP P10: Hollow structural Al-castings in HPDC

The overall motivation of this three-year project is the substitution of welded sheet components (e.g. ‘torque box’) by a hollow HPDC Al-SC exhibiting an increased stiffness and function integration at a lower unit weight in comparison to the conventional steel approach.Within this project MAGMA will develop models to for the simulation of the production of salt cores in HPDC and afterwards will focus on the behavior of the salt cores during the casting process. Therefore needed quality criteria will be developed.

More information about AMAP and all projects are available here: http://www.amap.de/