MAGMASOFT® autonomous engineering

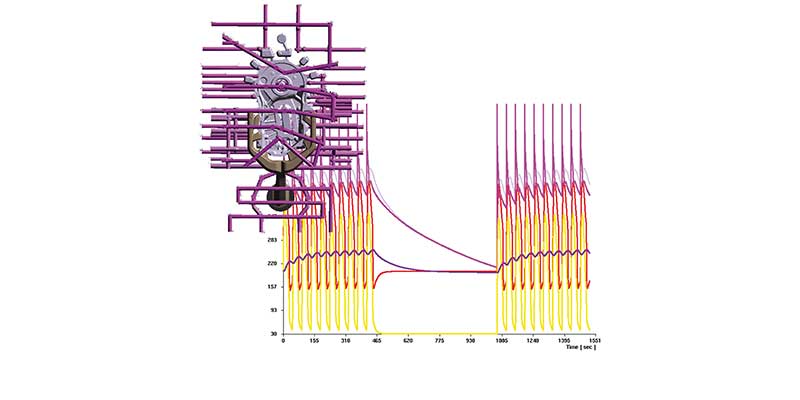

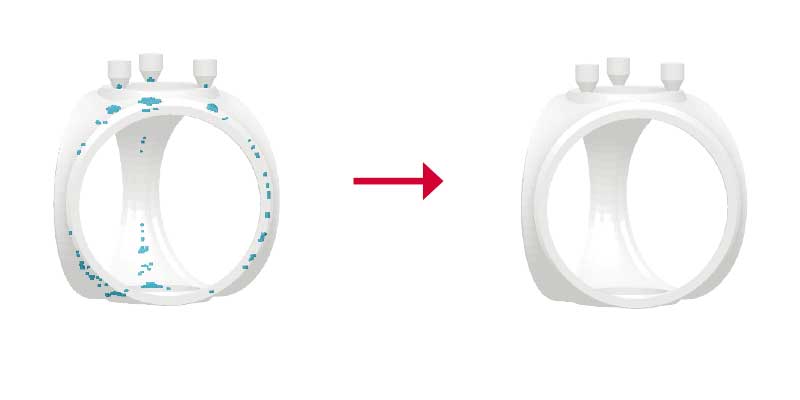

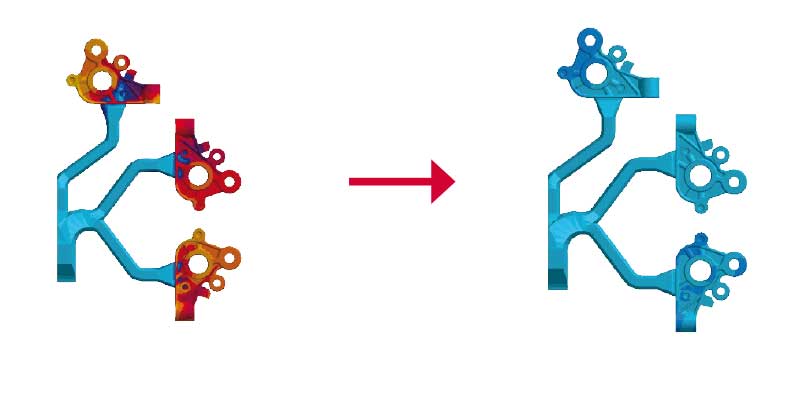

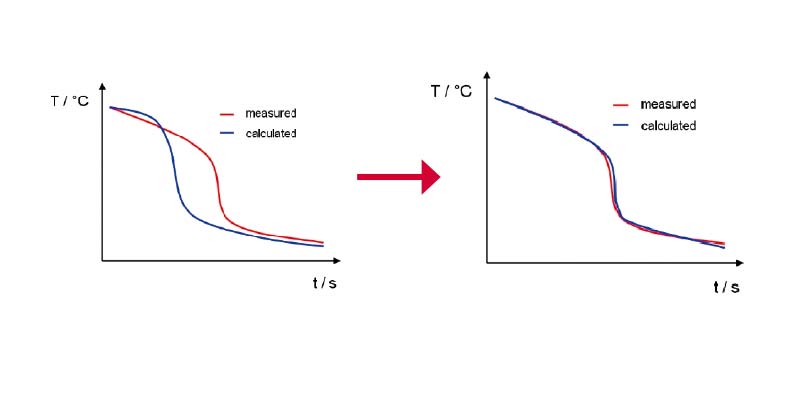

MAGMASOFT® is the comprehensive and effective optimization tool for improving metalcasting quality, optimizing process conditions and reducing production costs. Consequently utilizing the methodology of virtual Design of Experiments and Autonomous Optimization, robust process parameters and optimized casting layouts can be established for all cast materials and processes including heat treatment and melt metallurgy – efficiently and comprehensively at the same time.

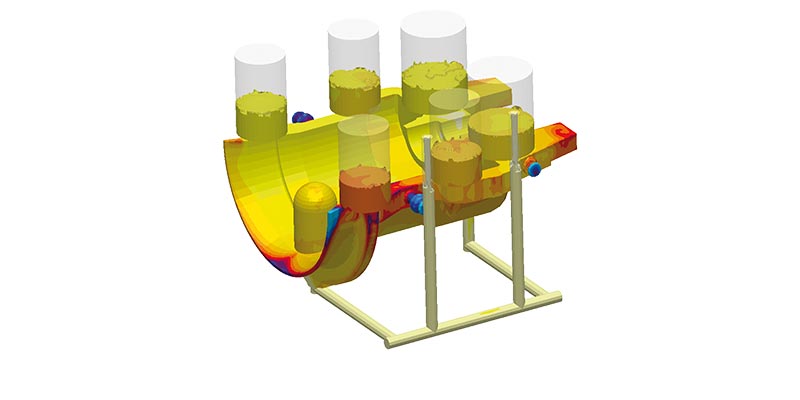

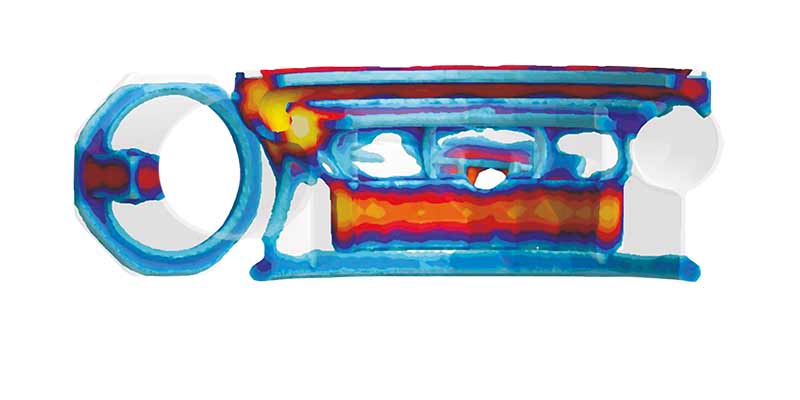

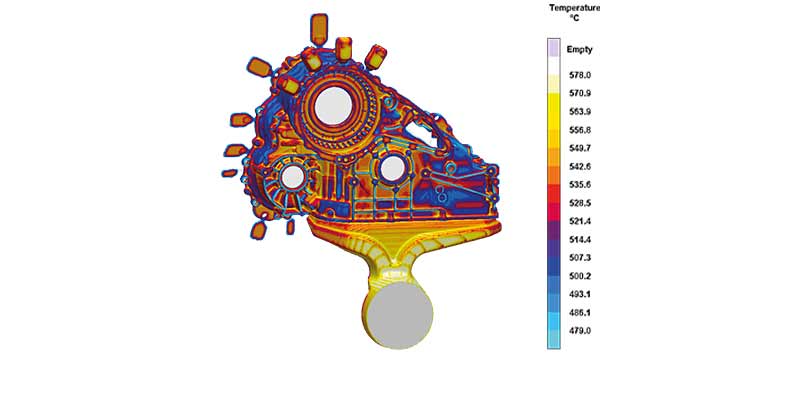

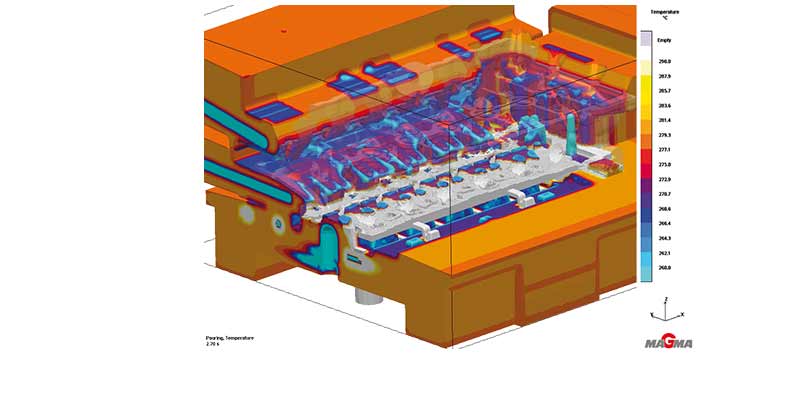

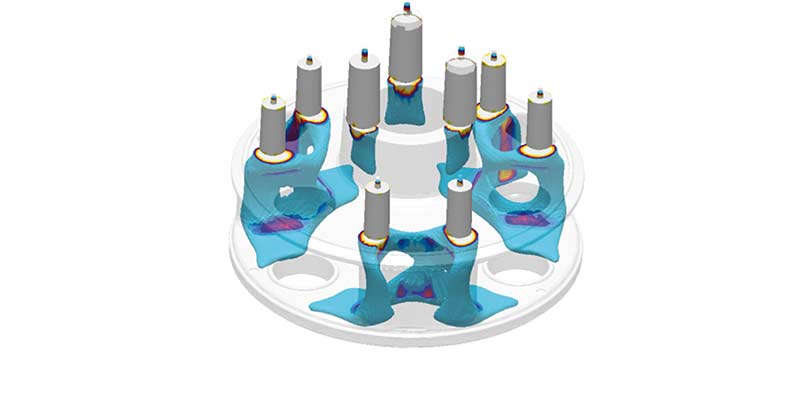

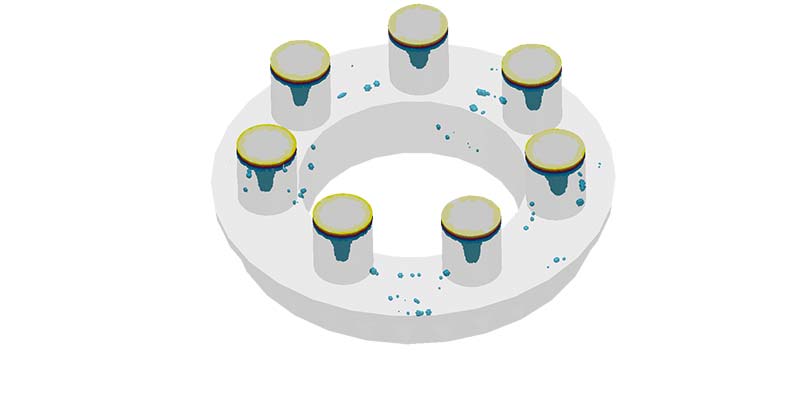

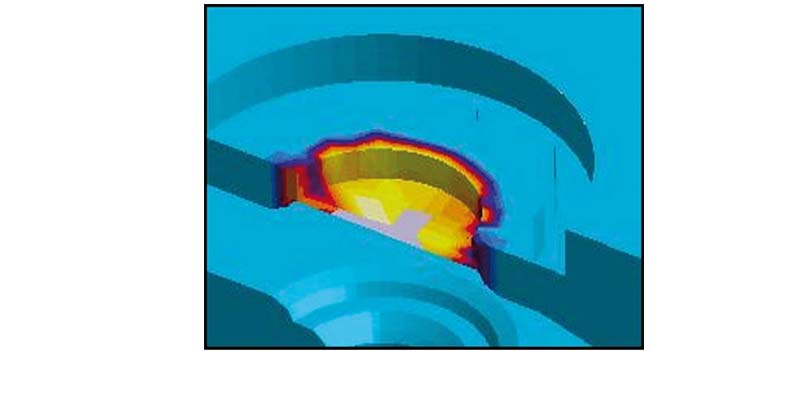

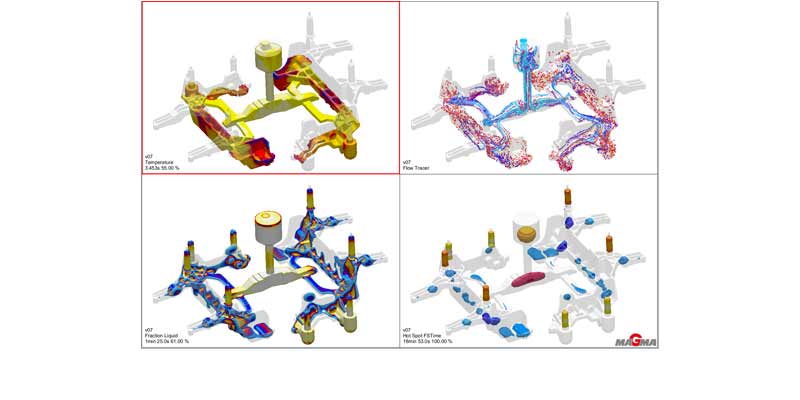

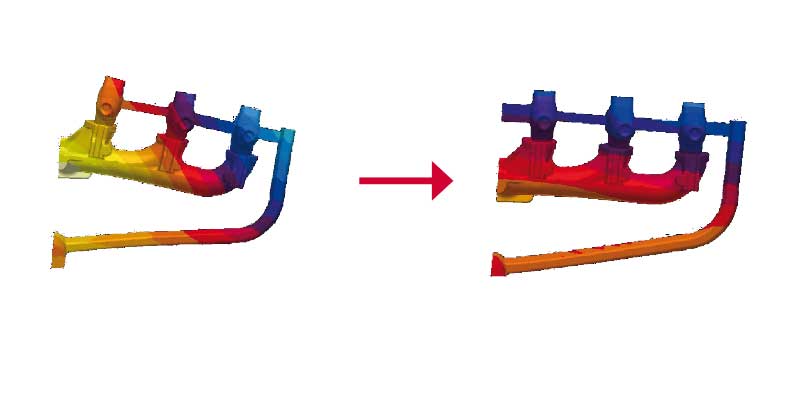

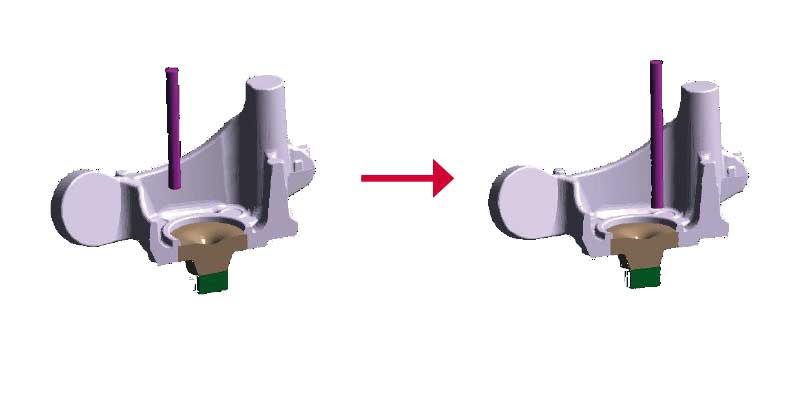

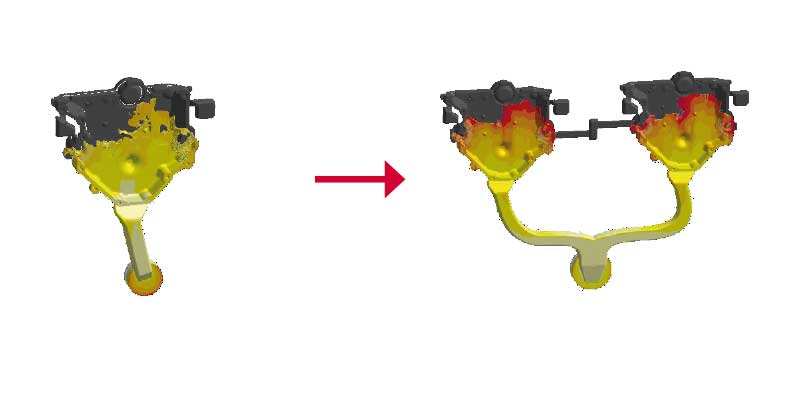

By means of Autonomous Engineering™, simulations with MAGMASOFT® can be used in an automated virtual test plan to pursue different quality and cost objectives simultaneously. Broad knowledge and tangible hands-on instructions/measures are generated considering design and process conditions for mold filling, solidification and cooling. The range of results comprises residual stresses and distortion, microstructure formation and local properties.

A modular software design covers the complete process chain of cast components. The software can be applied for optimized process robustness and part quality from conceptual to final component design, during the tooling layout and prototyping, all the way through to the production and heat treatment processes.

MAGMASOFT® offers the following main benefits:

- Supports all cast materials and all aspects of casting manufacture including melting and metallurgy, pattern and coremaking, cleaning and repair

- Offers a virtual test field for the reduction of metalcasting defects with high degrees of freedom without production risk

- Establishes optimized operating points for quality, yield and cost

- Identifies optimal process conditions for robust process windows early and reliably

- Allows faster decision making to establish saving time for all parties involved

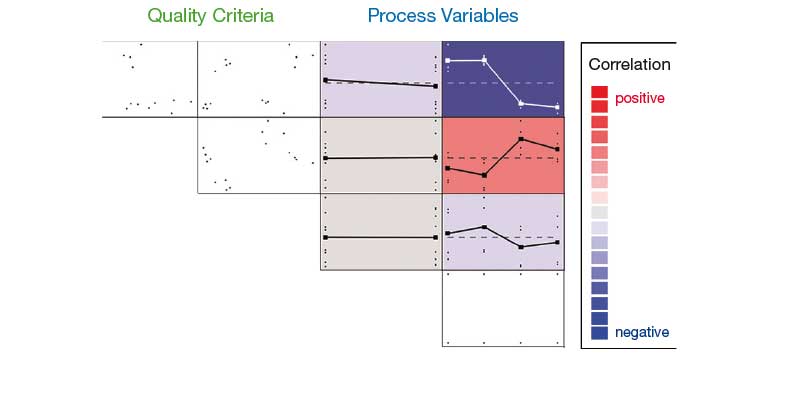

- Empowers quality management by generating systematic understanding how process variability affects quality

- Improves communication and confidence within your company and in cooperation with customers

- Offers reliable and early information to designers for robust product and process development

MAGMASOFT® standard has a modular structure and contains the following functionalities for a comprehensive simulation:

- A common graphical user interface for all modules

- A project management perspective for handling of simulation and optimization projects

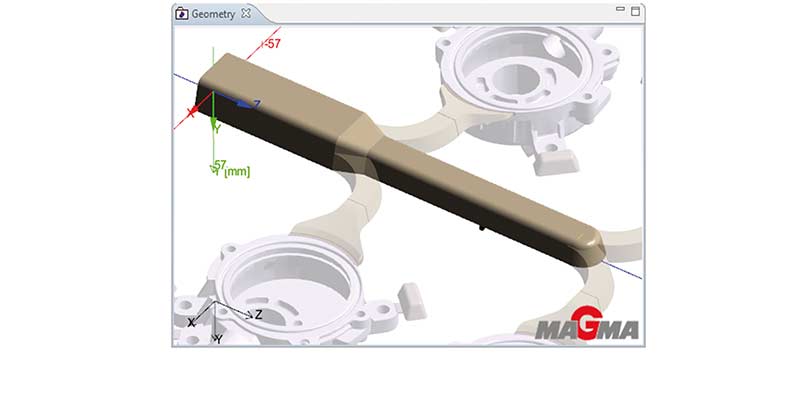

- Parametric Solid Modeling of geometries using a CAD kernel as well as import and export of CAD data

- Automatic meshing of geometries for the simulation

- Comprehensive process mapping with direct access to all materials, process steps and the corresponding simulation settings

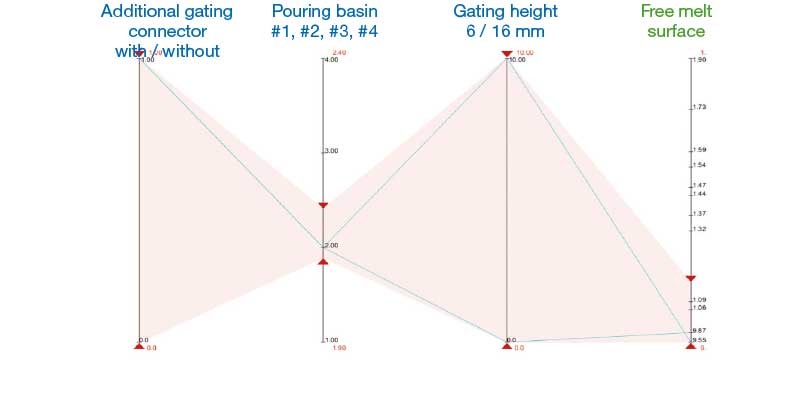

- Definition of virtual designs and parameters for optimization runs

- Simulation programs for the calculation of mold filling, solidification, cooling and serial casting applications

- Interactive and automatic result evaluation: Several perspectives can be opened and edited at the same time

- Result perspective for comprehensive visualization and evaluation of simulation results

- Easy quantitative assessment of virtual Design of Experiments or optimization runs

- Database module to manage thermo-physical and other relevant process data required for simulation

MAGMASOFT® is modularly expandable

MAGMASOFT® can easily be linked to additional modules for specific processes, materials or quality aspects.

MAGMAiron, MAGMAsteel, MAGMAnonferrous

Material-specific modules allow the prediction of microstructures and properties and consider alloys and metallurgy.

MAGMAhpdc, MAGMAlpdc, MAGMApermanent mold, MAGMAwheel, MAGMAinvestment casting

Process modules allow the consideration of specific process requirements and to control the manufacturing process.

MAGMAc+m (core and mold), MAGMAdielife

Products and functionalities for the prediction of core shooting, gassing, and purging and the assessment of die life aid in making the best use of available knowledge.

MAGMA HT thermal, MAGMAstress, MAGMAlink, MAGMAdielife

Modules for simulating stresses of the component after casting, heat treatment, or machining and the exchange of information based on simulation results, assures the design of cast parts for their performance.

Latest Publication

MAGMASOFT® 6.1 – Efficient Optimization of Processes and Profitability

With new functionalities and extensive enhancements, MAGMASOFT® 6.1 offers comprehensive support for optimizing low pressure die casting processes and facilitates the design of die-cast parts. A specially developed process module for rheocasting and thixomolding processes adds numerous new options for users in core production and continuous casting.

In addition, the newly introduced ECONOMICS Perspective enables, for the first time, a quantitative evaluation and optimization of both costs and CO₂ emissions for all simulation projects, improving both the profitability and the sustainability of all applications.

System Requirements

MAGMASOFT® is available for all suitable current operating systems such as Linux and Windows. MAGMASOFT® can be used on multi-processor computers or massively parallel on cluster computers.