The quality, cost-effectiveness and competitiveness of cast components is driven by the design of the casting, the productivity and reproducibility of the process, as well as the properties of the cast part after all relevant manufacturing steps.

As your independent partner and a provider of engineering services with decades of technological casting competence, MAGMA Engineering supports you in all key factors of your competitiveness - knowledge and competence - time and efficiency - costs and cost-effectiveness.

MAGMA Engineering is an interdisciplinary and international team of experts with over 25 years of experience in solving complex casting-related problems.

MAGMA Engineering stands for state of the art casting process simulation, for innovative and robust products and processes, as well as competent expertise in the areas of development, design, process optimization in metal casting.

MAGMA Engineering supports you using casting process simulation

- over the entire range of cast materials

- for prototyping and small series production or mass-production applications

- over the entire value chain of a cast product – from the initial product idea to the continuous optimization of series production

- across the entire organization– from design and development through purchasing to supply management

How can we assist or support you?

- Carrying out virtual feasibility studies and process window evaluations

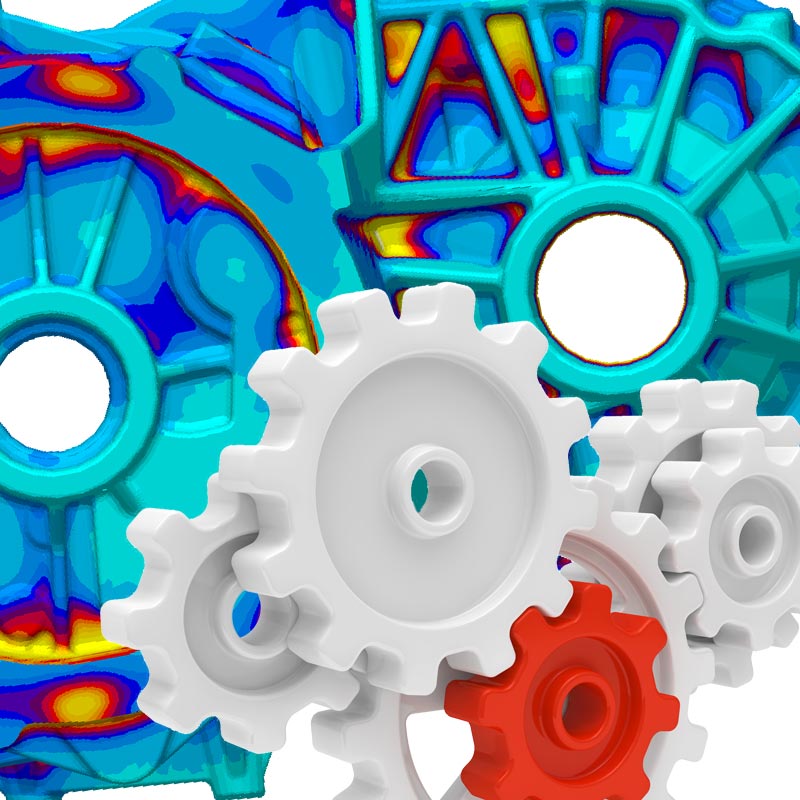

- Optimization of casting designs regarding the material and process capabilities to realize lightweight construction

- Casting layout conception targeted at robust production processes

- Design of tooling and process technology, for instance thermal regulation to reduce return material, energy consumption and scrap with a maximum tool lifetime

- Validation of required specifications through quantitative prediction of casting and tooling properties

- Analysis of local residual stresses and the distortion of castings and tooling over the entire process chain

- Reduction of development and response times through virtual sampling of cast components

- Trouble-shooting in the run-up to SOP and series production

- Systematic analysis of casting defects and the process to evaluate root causes

- Fast feasibility checks and the evaluation of constructive changes and potential alternatives

- Optimization of tooling and process settings over the entire value chain, from melting through casting to heat treatment

- Reduction of molding material consumption, optimization of shake-out times, minimization of cleaning costs, part machining and repair welding

- Accompanying of research and cooperation projects

- Supporting communication between design, production and quality to achieve project milestones and goals faster and more reliably

- Promotion of fair, profitable and long-term relationships between casting buyer and metalcaster

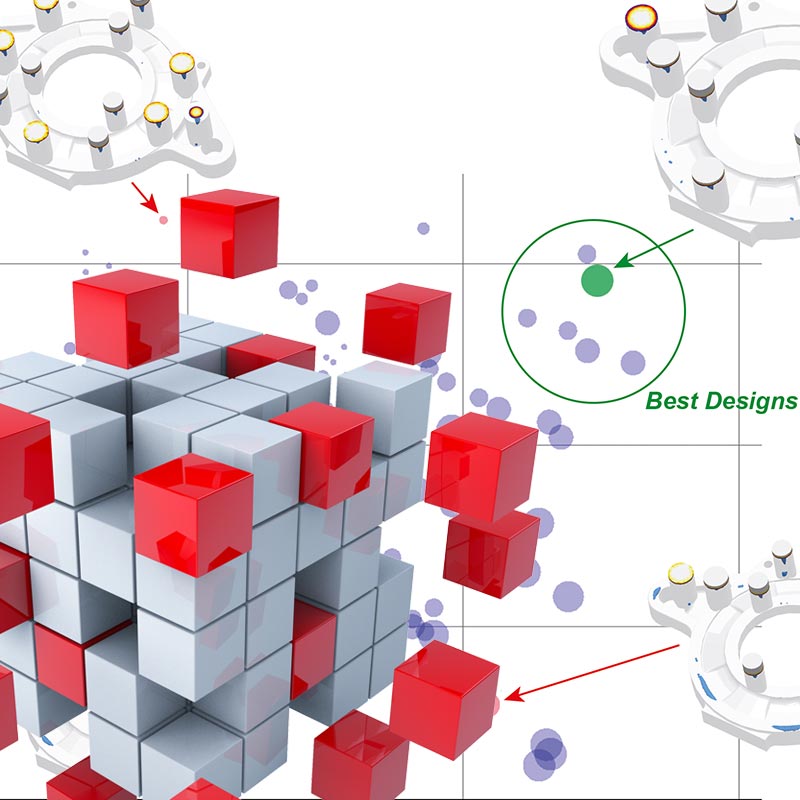

- Performance of methodological product or process studies on correlations between production parameters and quality characteristics

- Generation of systematic knowledge about the casting process as a basis for innovative improvements

Our experts use the full range of the MAGMASOFT® product portfolio to provide simulation solutions fit to your needs, overcome capacity bottlenecks, extend your process expertise, or independently secure results. Even if you are simply looking for new impulses, we are there for you. Our experts compile and document step-by-step improvements and potential solutions - from a simple solidification simulation, to a full factorial design of experiments (DoE) or an autonomous optimization of your casting process. MAGMA Engineering supports you in designing robust products and processes within the scope of your degrees of freedom.

ISO 9001 certified

MAGMA is your certified partner for the implementation of development services according to ISO 9001.

MAGMAengineering Contact

MAGMA Giessereitechnologie GmbH

Kackertstr. 16-18

52072 Aachen

Germany

Phone: +49 241 88901 0

Fax: +49 241 88901 119

Reliable Castings and Robust Quality for Designers and Supply Chain Experts

The design process of cast components is driven by more than just functionality. Meeting other key criteria such as cost-effectiveness, resource efficiency, castability, process robustness and quality in a minimum of time presents fundamental challenges during the stages of component conception and design.