Targeted Heat Treatment

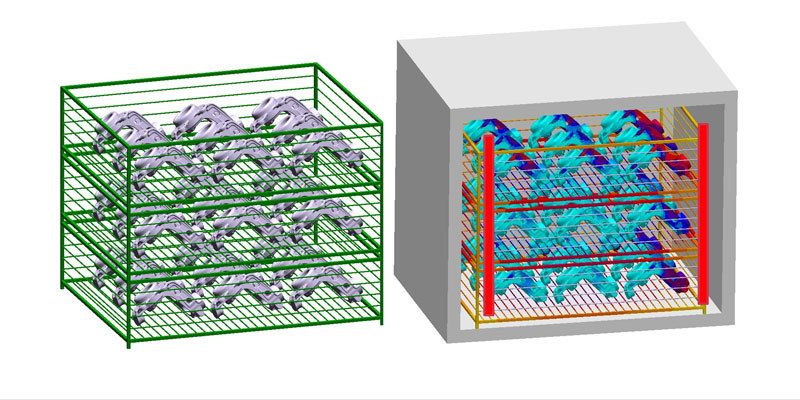

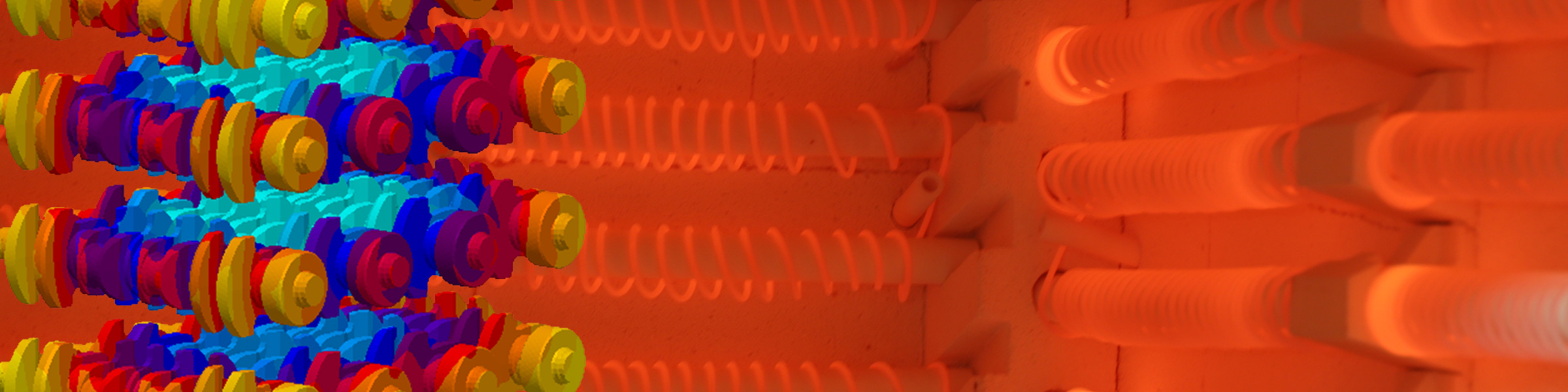

Following the casting process, many castings undergo a heat treatment with the aim of achieving the desired microstructure as well as the required mechanical properties. In the heat treatment module of MAGMASOFT®, the temperature distribution in the casting during each heat treatment step is calculated based on the following parameters:

- Furnace temperatures

- Process times

- Process temperatures

- Quenching media and temperatures

The virtual optimization of heat treatment processes allows:

- Reduction of process times in the furnace

- Assessment of the heat treatment demand to realize the required microstructure, residual stress distribution or mechanical properties

- Analysis of the influence of process variations on microstructures and material properties

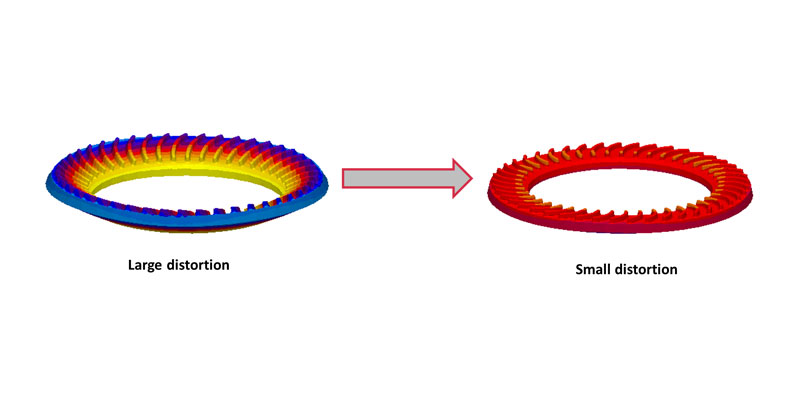

- Minimization of the distortion of castings during the heat treatment process

- Reduction of costs for extensive experiments and development times

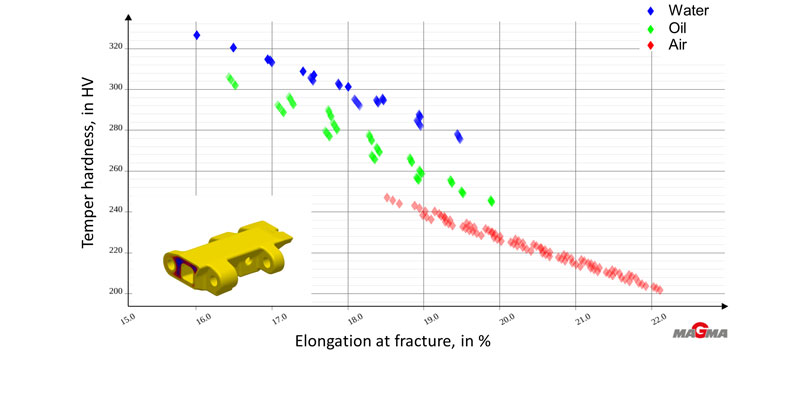

Virtual experiments allow the systematic variation of tempering temperatures and times of steel castings, to find an optimal compromise between strength and ductility.

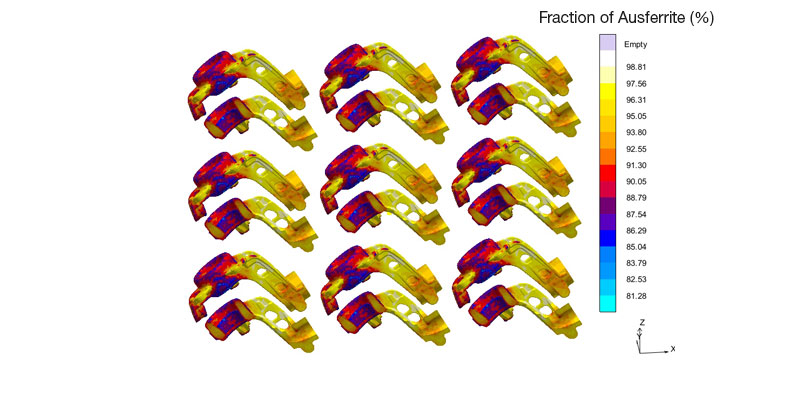

The calculation of the relief of residual stresses from the casting process, for example for stress relief annealing of iron castings, can be carried out. In cast iron, in addition to conventional stress relief annealing and pearlitization, the optimization of the complex production process to produce austempered ductile iron (ADI) is possible.

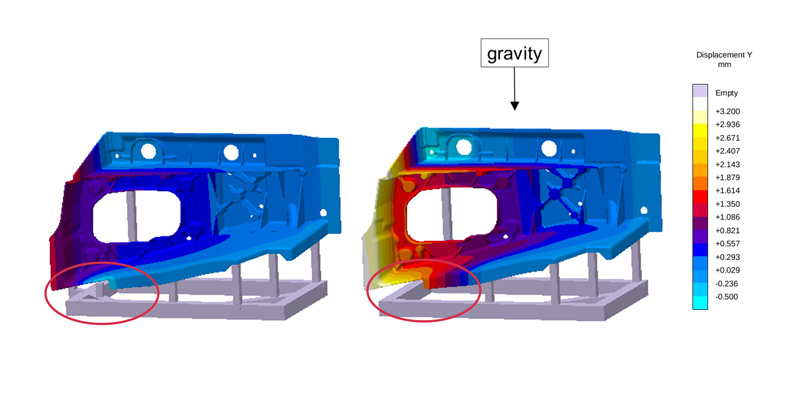

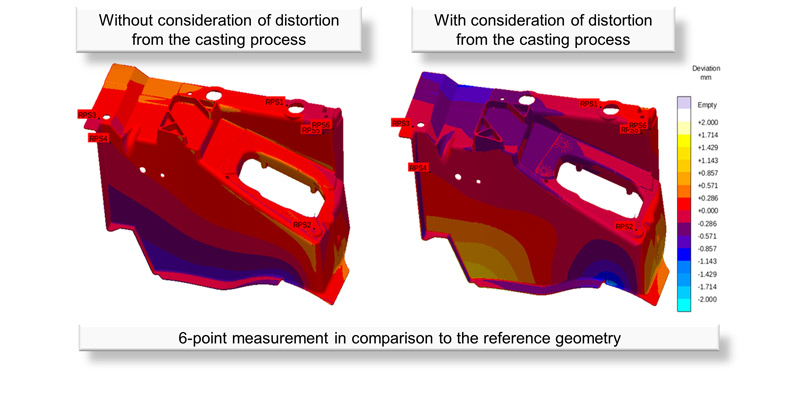

For structural components made of aluminum, among others, the design of heat treatment supports can be optimized with the help of residual stress calculations during heat treatment.

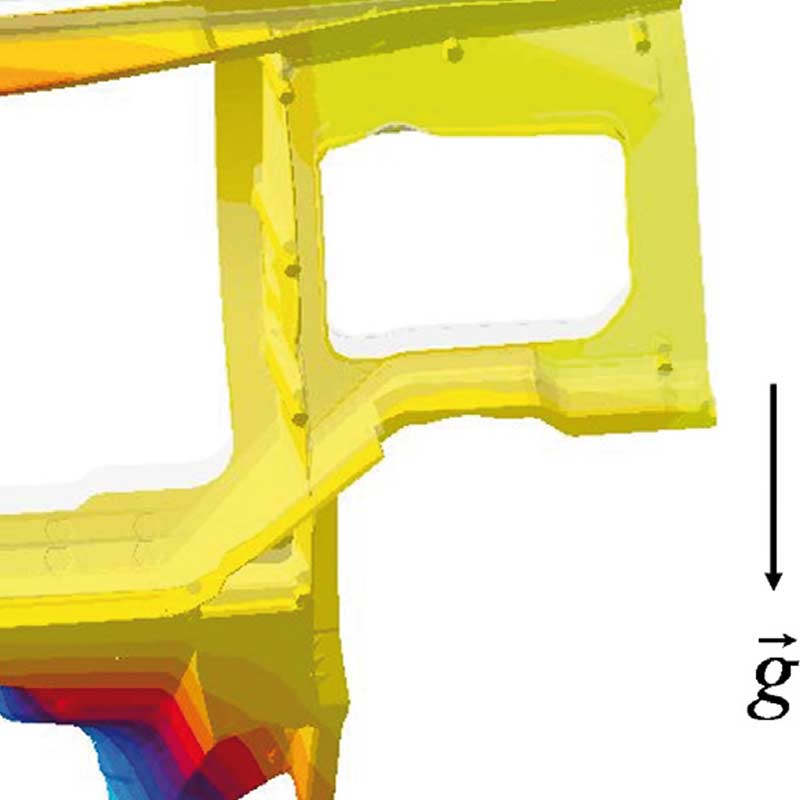

The risk of crack formation due to high temperature gradients during the quenching of castings can be minimized through corresponding process and design optimization.

Case Study Heat Treatment

Casting Distortions During Solution Treatment

Aluminum castings are often heat-treated to increase mechanical properties and simultaneously decrease thermal stresses induced by the casting process.