Aluminum DC Casting Process With MAGMA CC

The direct chill (DC) casting process is integral to the manufacturing of semi-finished products. In this process, liquid metal is introduced into a short, intensely cooled mold from a launder. Simultaneously, metal is withdrawn from the mold, requiring the establishment of a stable solidified shell at the mold's exit. MAGMA CC, a fully integrated turn-key solution, plays a crucial role in simulating and optimizing both vertical and horizontal DC casting processes.

Key features:

- Robust solutions for aluminum production with DC and CC casting processes

- Design process conditions for optimized flow and solidification, enhancing product quality

- Integrated simulation of casting stresses, including cracks and hot tears, for comprehensive process evaluation

- Integrated process chain for casting with subsequent forging and rolling processes

Process Simulation Capabilities Include:

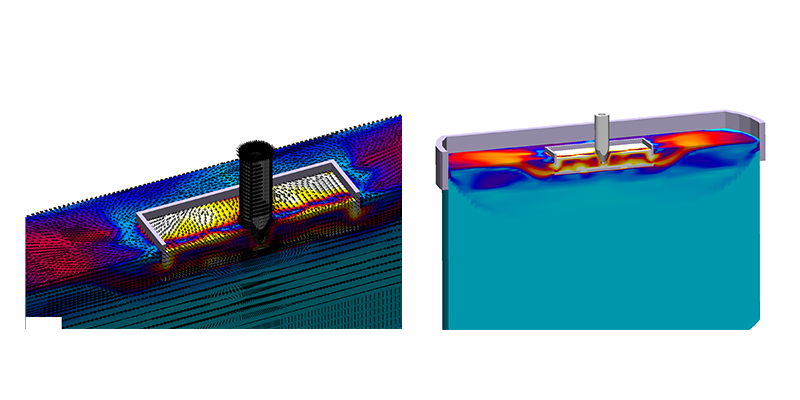

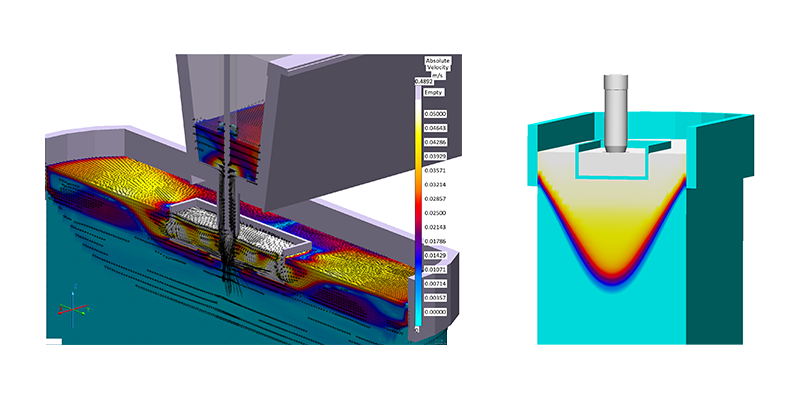

- Realistic representation of the entire DC casting process, assessing flow conditions during start-up and strand withdrawal

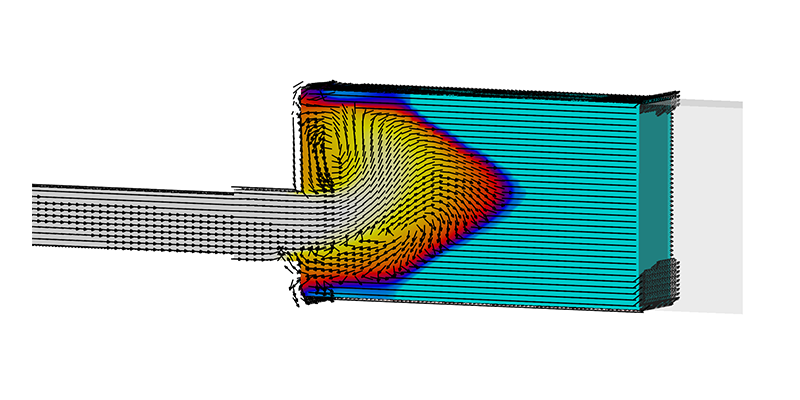

- Consideration of forced and natural convection in the liquid metal and in the mushy zone

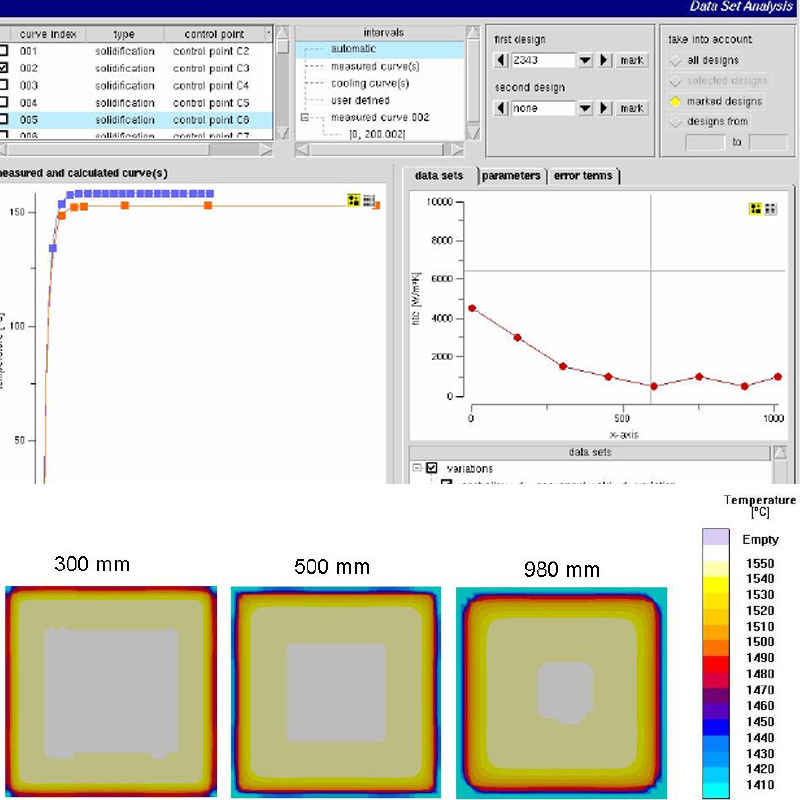

- Determination of the stationary temperature distribution in strand and mold, allowing the evaluation of influencing parameters

- Accurate prediction of the sump profile and assessment of optimal process parameters for improved energy efficiency

- Calculation of the solidification front to prevent bleedout and evaluation of thermal gradient and cooling rate

- Assistance in achieving high productivity as well as cost and energy efficiency

- Reduced porosity, shrinkage, and optimization of launder and distribution design

- Virtual design and optimization of the direct chill casting process

Publication in Area of Continuous Casting

Autonomous Mathematical Optimization of Continuous Casting Processes

Editors:

Wilfried Schäfer, Götz Hartmann, Erik Hepp, MAGMA GmbH, Aachen, Germany

Dieter G. Senk, Sonja Stratemeier, IEHK RWTH Aachen University, Germany

The publication introduces a numerical simulation based optimization strategy, following rigorous thermodynamic and thermo mechanical models as well as a strictly methodic approach.