MAGMA CC – More Simulation for Continuous Casting

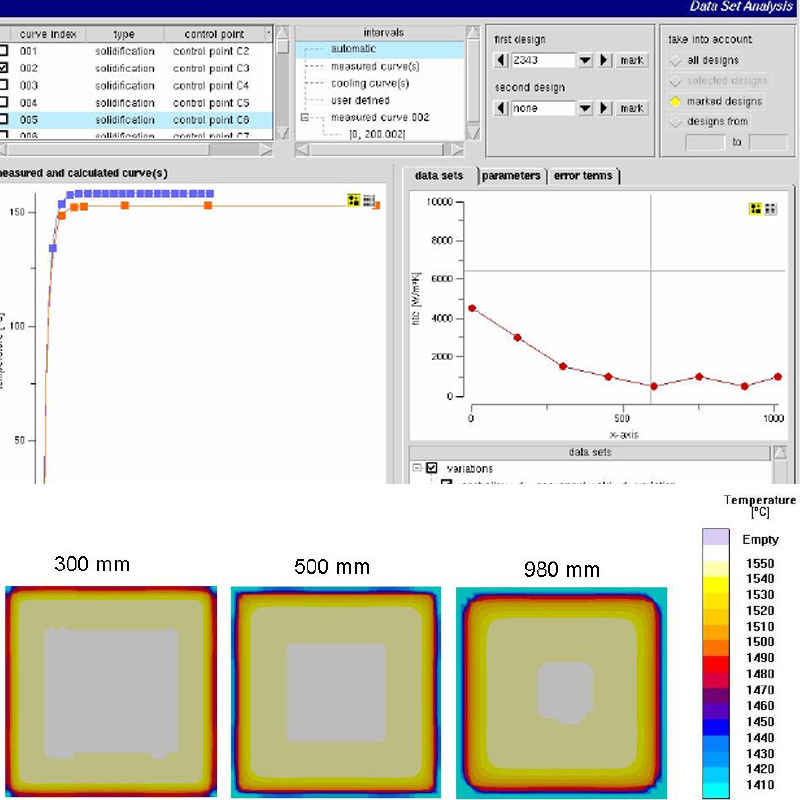

The continuous casting process is of crucial importance for the manufacture of semi-finished products. Liquid metal is introduced into a short, intensively cooled mold, from a tundish or launder. At the same rate, metal is withdrawn from the mold, where the presence of a stable solidified shell at the end of the mold needs to be assured. In the start-up phase, a starting ingot is positioned in the mold, and after reaching the desired filling level, the starting ingot is removed and the metal inflow adjusted accordingly.

The primary cooling in the mold is of decisive importance for the formation of a stable solidified shell. Further cooling of the strand takes place in the so-called secondary cooling zone. For process design and optimization, MAGMA CC, is a fully integrated and practically relevant turn-key solution providing meaningful information for the simulation based optimization of vertical and horizontal continuous casting processes.

Publication in Area of Continuous Casting

Autonomous Mathematical Optimization of Continuous Casting Processes

Editors:

Wilfried Schäfer, Götz Hartmann, Erik Hepp, MAGMA GmbH, Aachen, Germany

Dieter G. Senk, Sonja Stratemeier, IEHK RWTH Aachen University, Germany

The publication introduces a numerical simulation based optimization strategy, following rigorous thermodynamic and thermo mechanical models as well as a strictly methodic approach.