Predictable Core Production

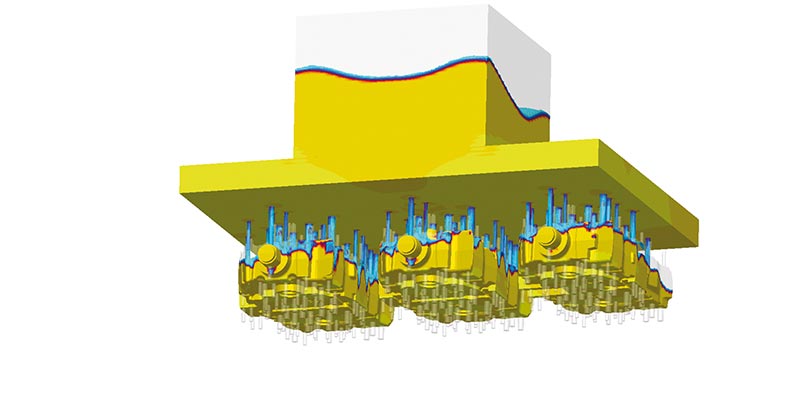

Sand core quality and profitability are driven by the core box design, the productivity of the process, reproducible manufacturing conditions for core shooting/blowing and curing, and the resulting core properties.

MAGMA C+M is capable of autonomously establishing robust process conditions and optimized solutions for sand core production including the shooting, gassing and curing of organic and inorganic binders for cold and heated core boxes. The integrated tools to statistically set up virtual Designs of Experiments and automatically assess results support toolmakers and coremakers in determining optimal design and process conditions, for example regarding:

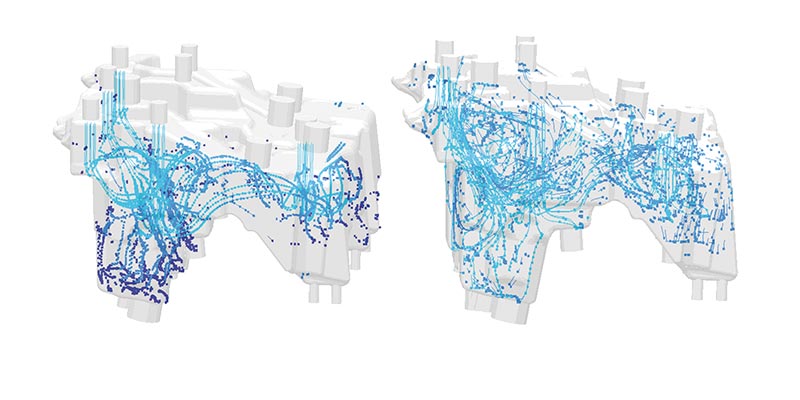

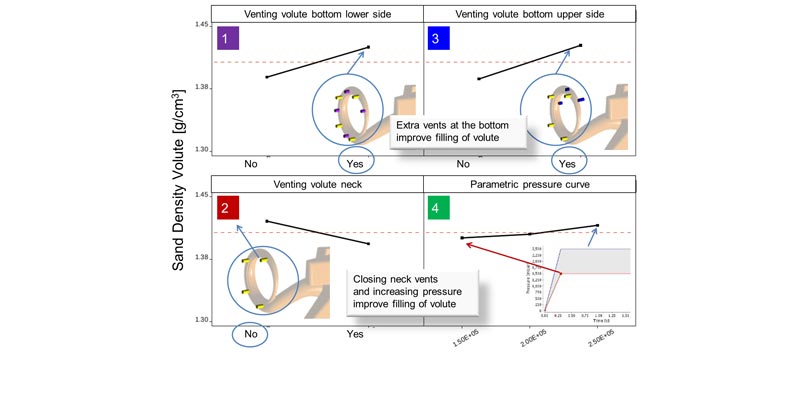

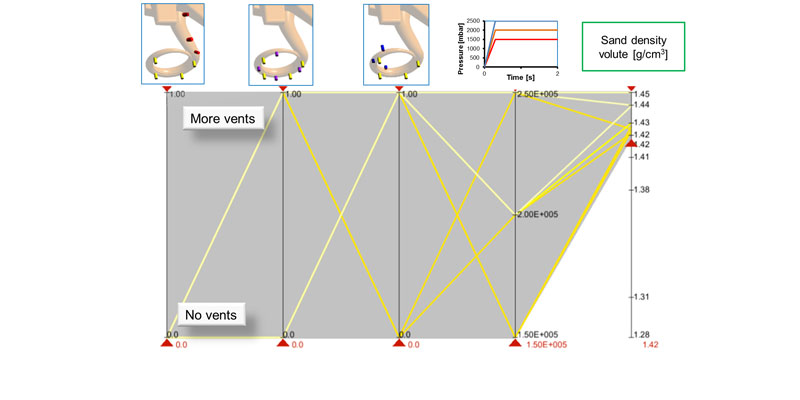

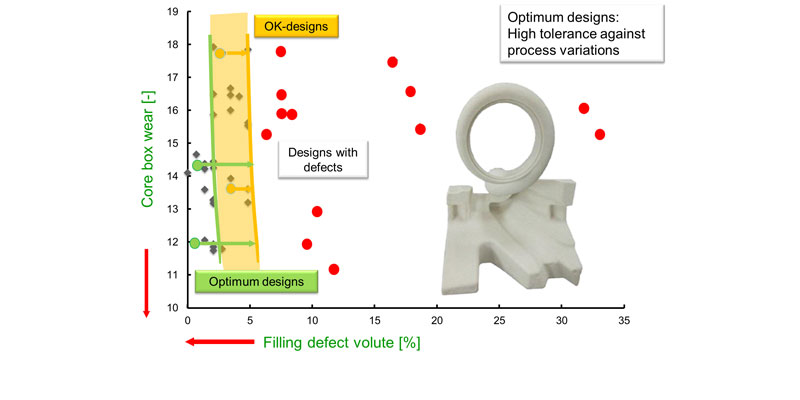

- Robust lay-outs and reduced core box wear through optimized blow tube and vent configurations

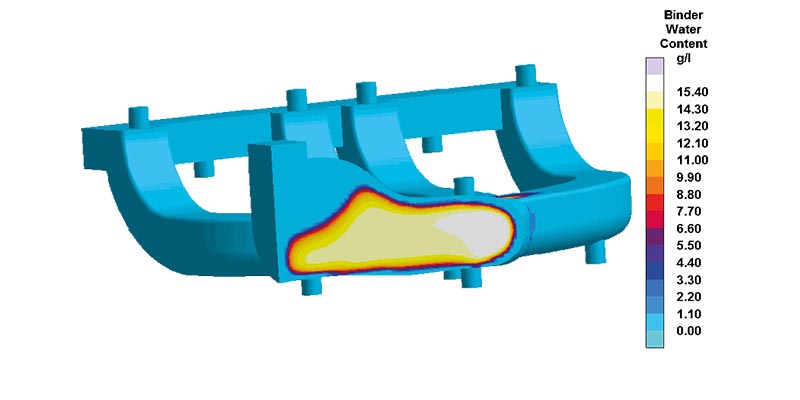

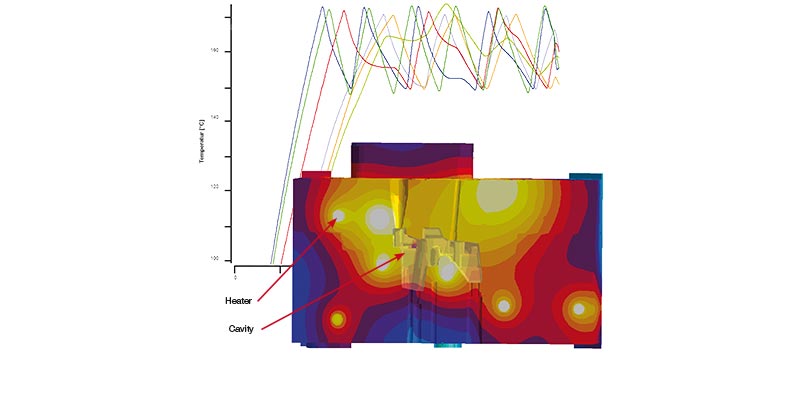

- Proven set-up of core box thermal control, determination of required curing times

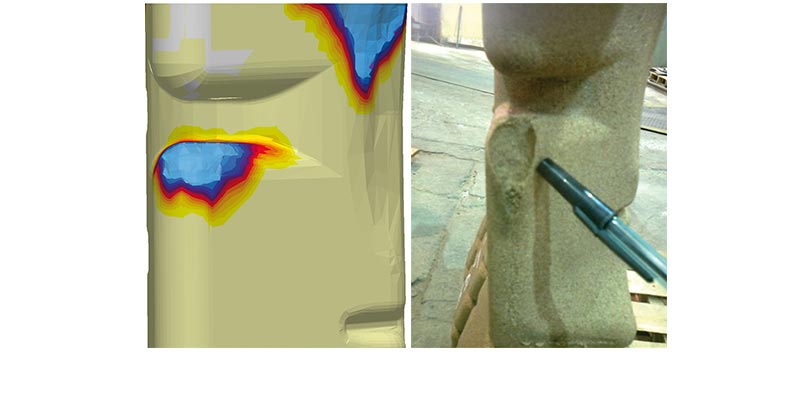

- Practice-oriented determination of robust process parameters for reproducible core shooting and gassing

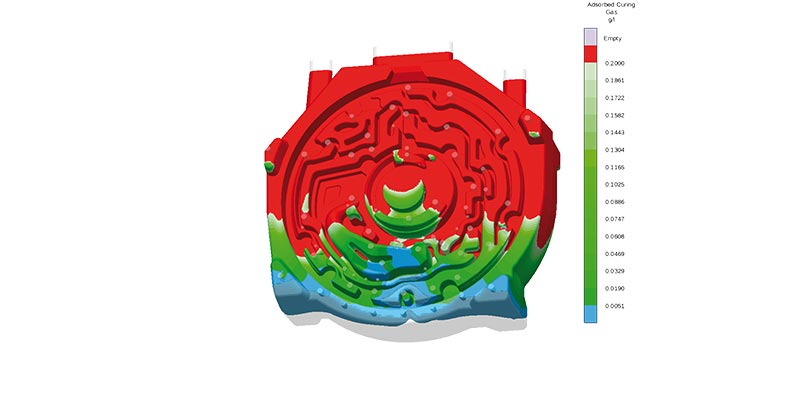

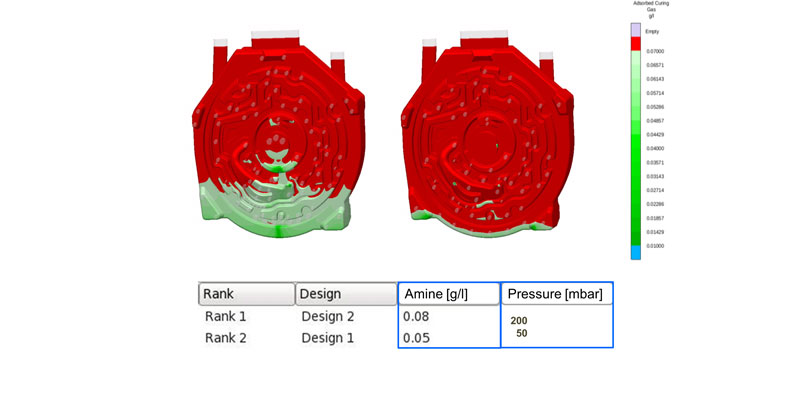

- Reduction of binder content and amine consumption

- Avoiding extensive trials and core box modifications on the shop floor

MAGMA C+M’s unique integrated methodology of virtual experimentation and autonomous optimization lets the software automatically run through various core box design and parameter combinations. MAGMA C+M helps identify a set of process conditions best meeting the specified requirements. This is done quickly and comprehensively, matching different objectives considering all driving forces decisive for core quality.

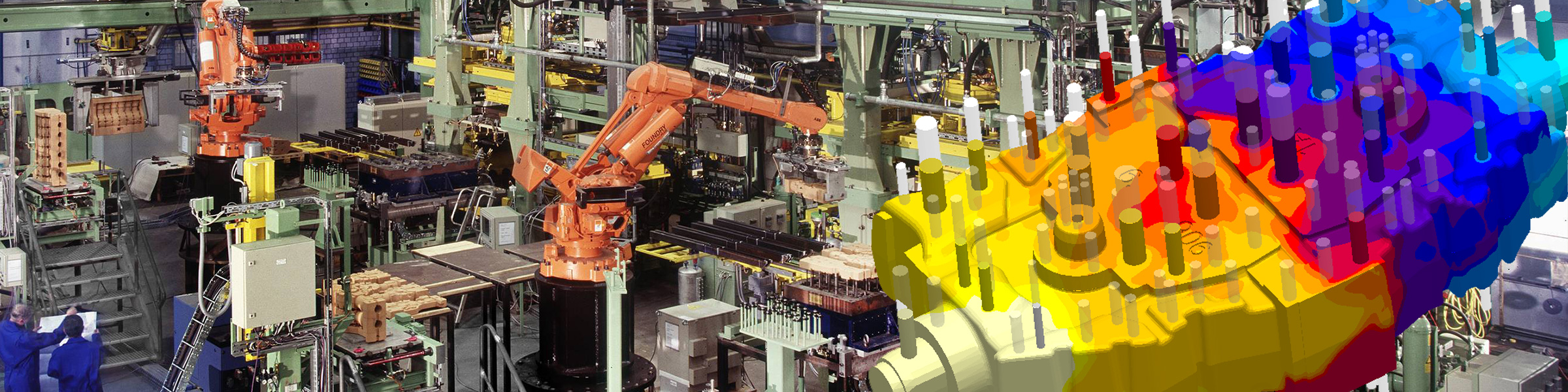

This makes MAGMA C+M key for toolmakers and coremakers to lay out optimal core designs, achieve reliable production processes, minimize quality risks, determine stable process windows and realize the full potential of the core material and production process without economic risks.

Core and Mold Reference

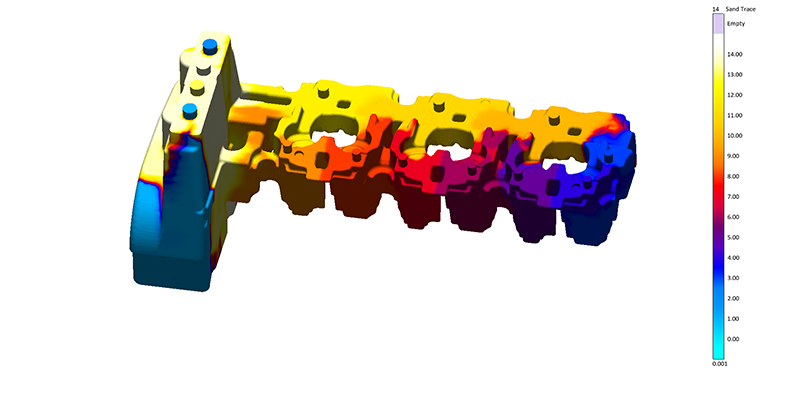

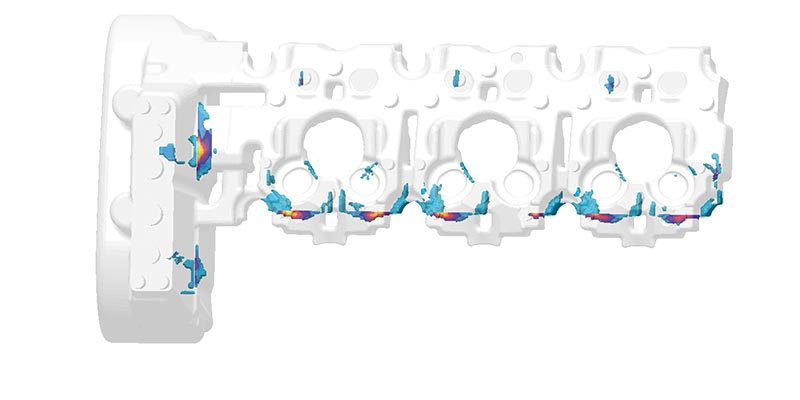

Optimization of the Shooting and Curing Process for a Complex Core

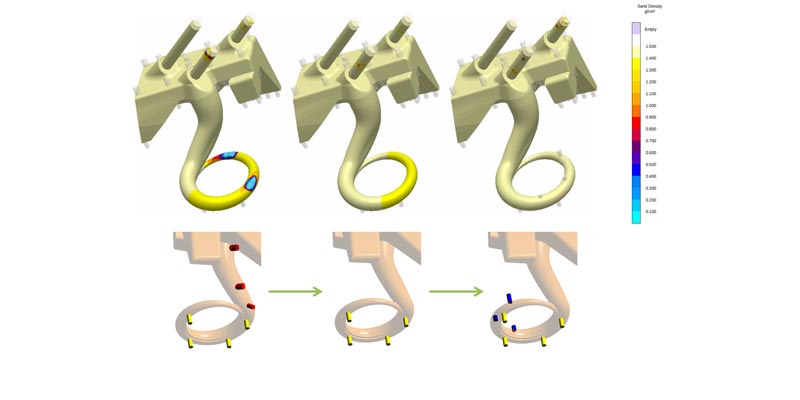

Usiminas recently introduced the new core making simulation software MAGMA C+M as part of their strategy to establish robust designs and processes for their core production line. The first project the software was applied to was already in progress at that time. Therefore, the main goal was to optimize the process conditions for the existing tooling lay-out.