Optimized Production of High Quality Steel Castings

The quality and profitability of steel castings are driven by the design of the pattern, the productivity of the process, reproducible manufacturing conditions and the properties of the cast material after casting and heat treatment.

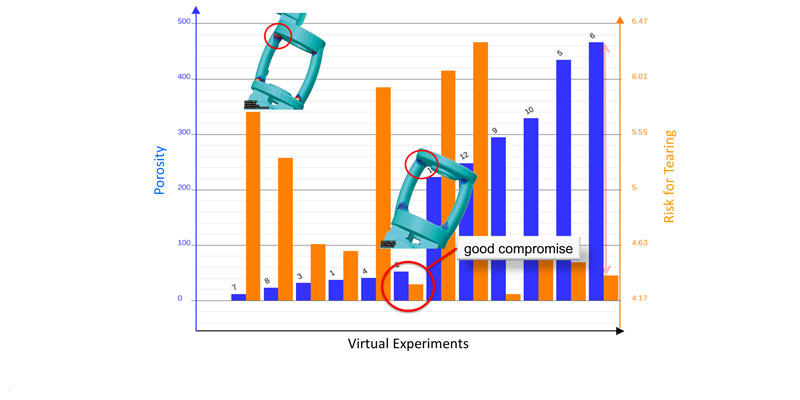

MAGMASOFT® is capable of autonomously establishing robust process conditions and optimized solutions for the pouring, solidification and heat treatment of steel alloys. The integrated tools to statistically set up virtual Designs of Experiments and automatically assess results support foundrymen in determining optimal design and process conditions, for example regarding:

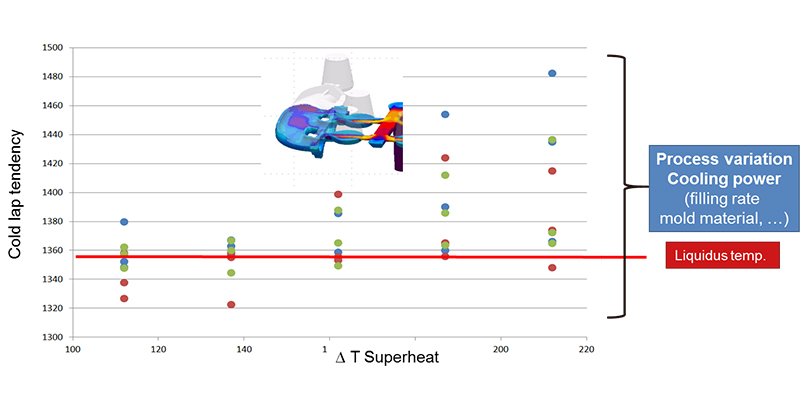

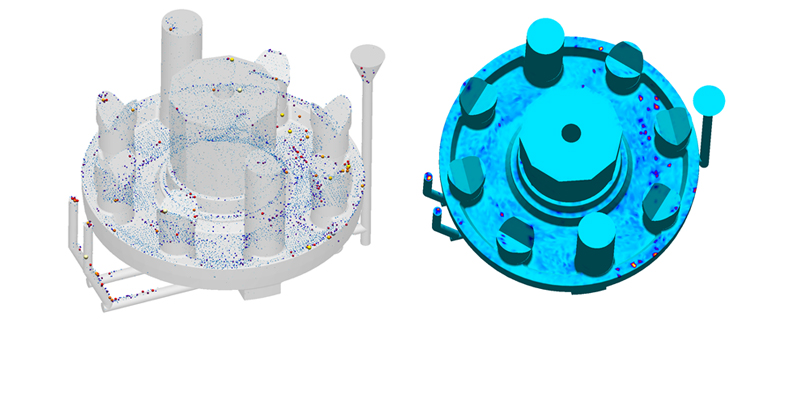

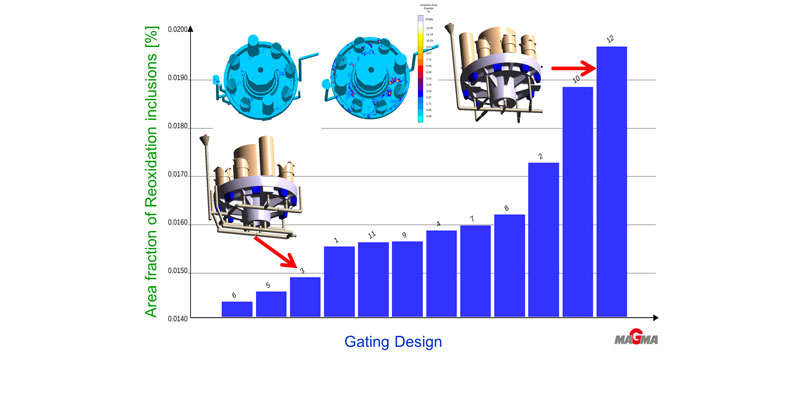

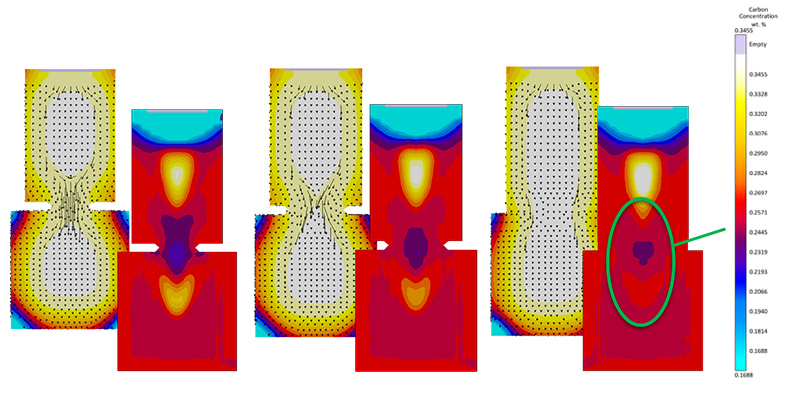

- optimization of gating/rigging for improved steel cleanliness and surface quality

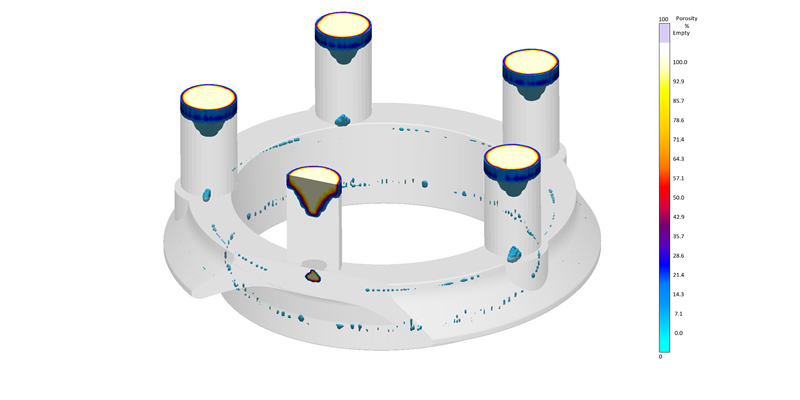

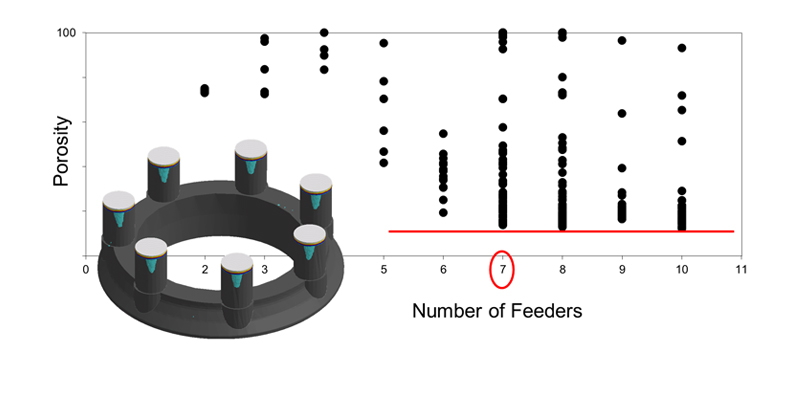

- elimination of shrinkage and porosity maintaining high yield levels

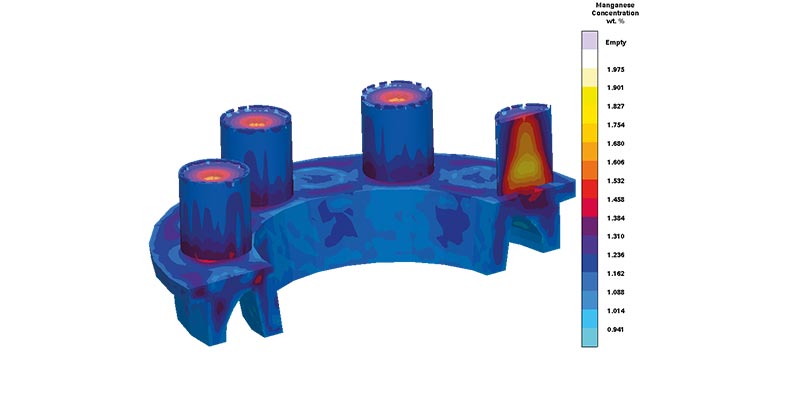

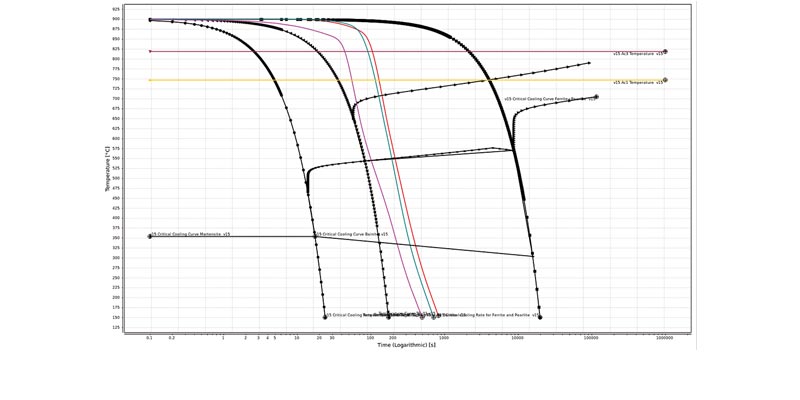

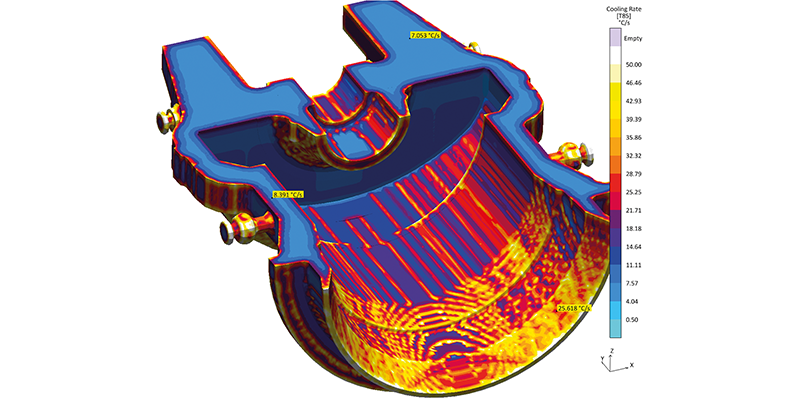

- prevention of critical phases during metal cooling including convection and segregation effects

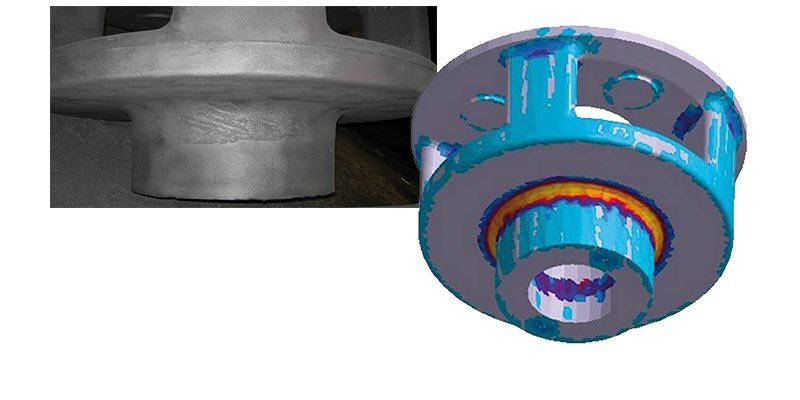

- casting design features such as minimized risk of hot tearing and dimensional tolerances

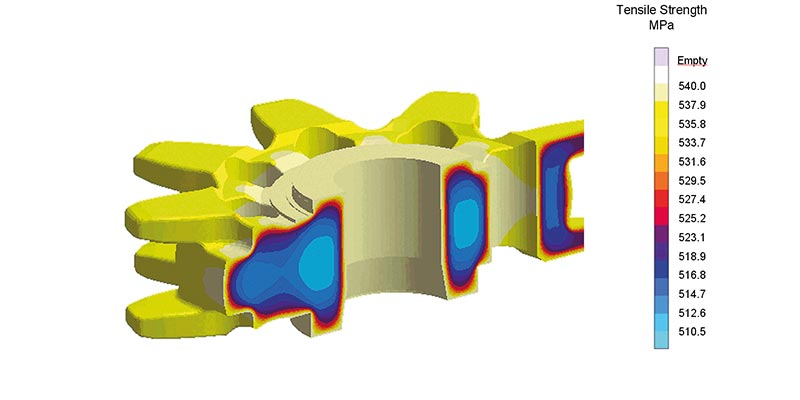

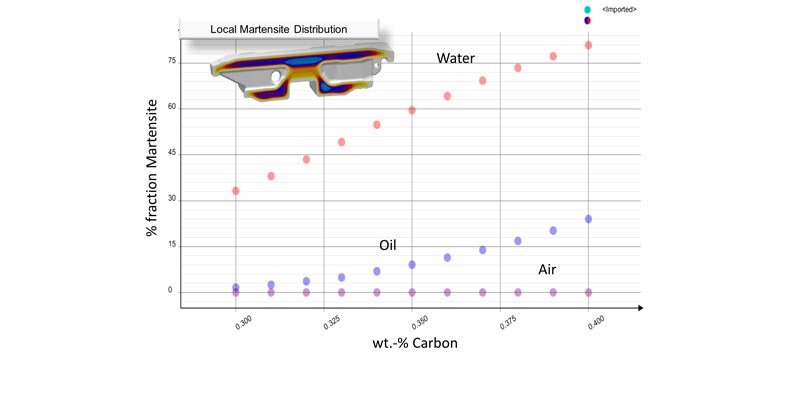

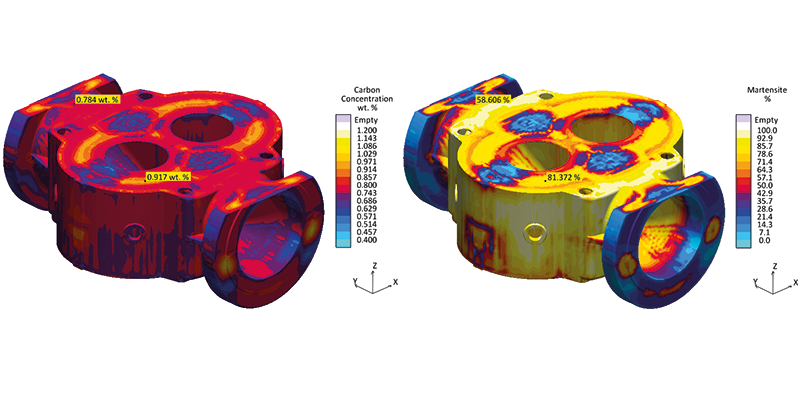

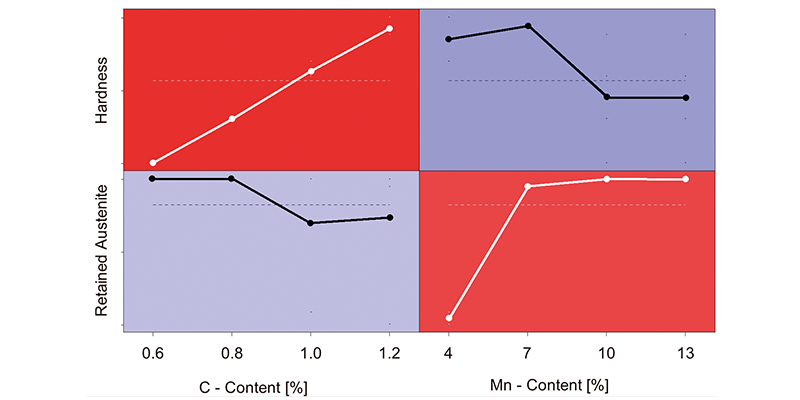

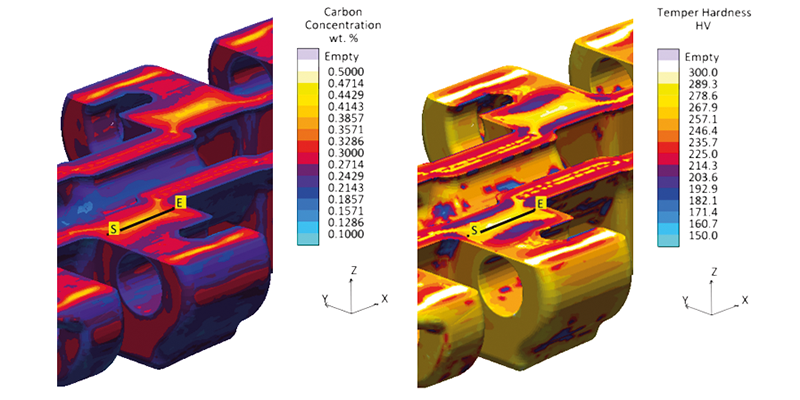

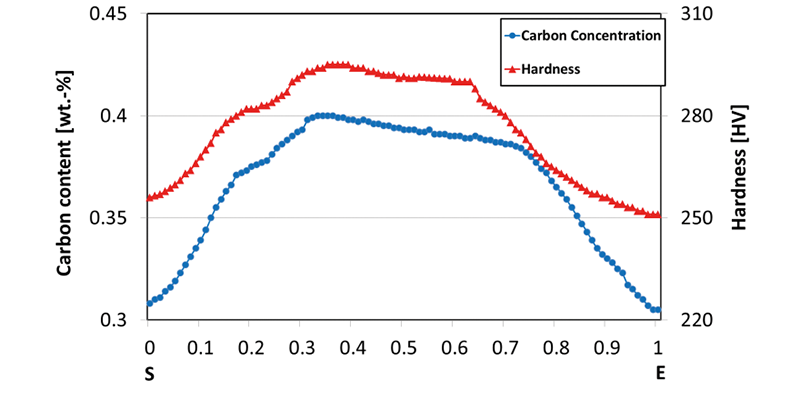

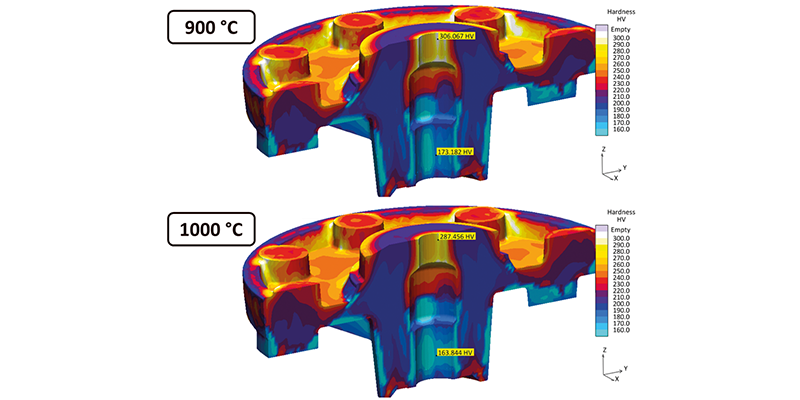

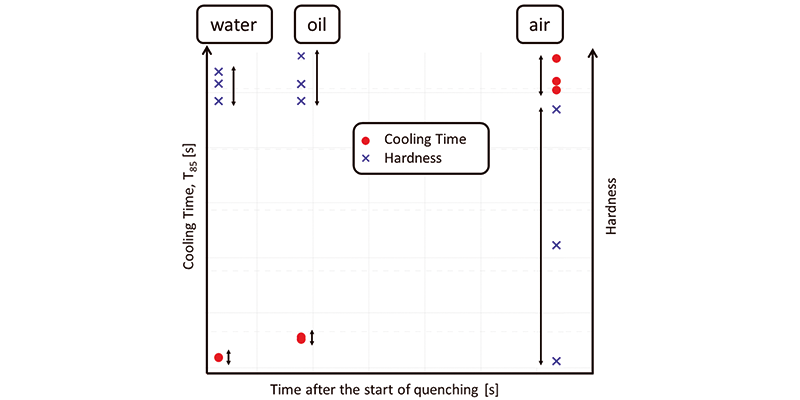

- resource conserving heat treatment processes tuned to achieve the desired microstructure and the required properties

MAGMASOFT®’s unique integrated methodology of virtual experimentation and autonomous optimization lets the software automatically run through various steel casting design and parameter combinations. MAGMASOFT® helps identify a set of process conditions best meeting the specified requirements. This is done quickly and comprehensively, matching different objectives considering all the driving forces decisive for steel casting quality.

This makes MAGMASOFT® key for cast steel part designers, pattern makers and foundrymen to lay out optimal cast part designs, implement reliable production processes, minimize quality risks, set up reliable process windows and realize the full potential of cast steel materials.

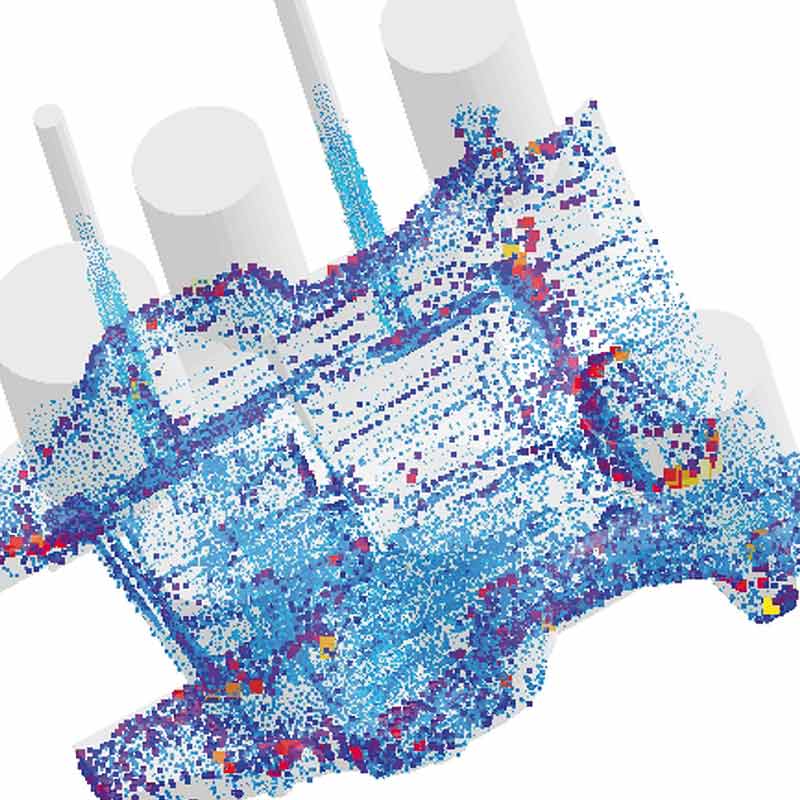

Our Latest Steel Casting Reference

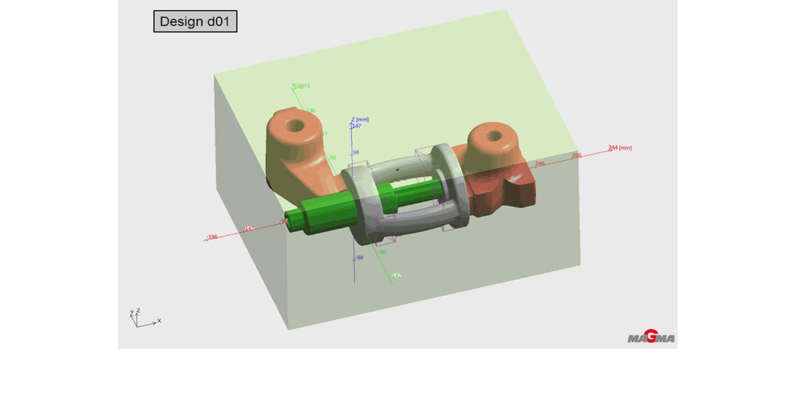

Optimization of Steel Casting Design and Methoding