EUROGUSS 2026:

Come and meet us at our booth 4-342 in Hall 4 on January 13-15, 2026, to learn how to innovatively and sustainably enhance your high pressure die casting processes with MAGMA and MAGMASOFT® autonomous engineering.

What to Expect at Our Booth

This year, we will show you, among other things:

- How to optimally balance quality, costs, and sustainability with MAGMA ECONOMICS,

- How to model both thixomolding and rheo-casting processes in detail with MAGMAsemisolid,

- How to efficiently simulate giga casting and zinc die casting with MAGMASOFT®,

- How to benefit from our engineering expertise in the successful implementation of MAGMASOFT®.

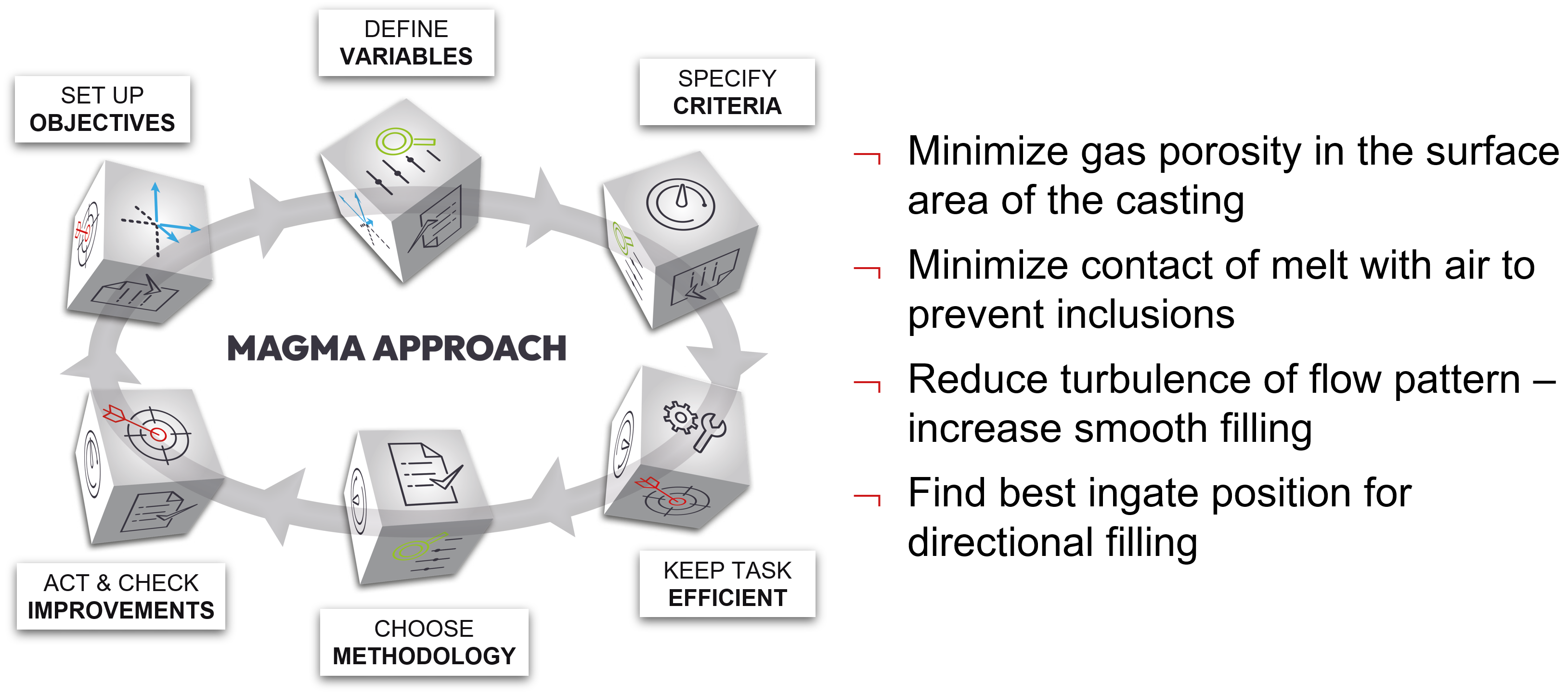

Use MAGMA ECONOMICS to Consider and Evaluate MAGMASOFT® Simulation Results for Die Casting

In the current economic and geopolitical situation, targeted measures to save energy, conserve resources and minimize the CO2 footprint are significant factors in national and international competitiveness:

MAGMA ECONOMICS supports you in achieving technical goals and saving CO2 at the same time! MAGMASOFT® is complemented by automatically provided information on cost and resource consumption data for each simulation. This innovative approach enables users to pursue technical and economic goals simultaneously. MAGMASOFT® thus becomes a powerful management tool for users and decision makers. Customers simultaneously pursue the desired technical and commercial objectives, compare simulations with cost and resource data and make informed decisions that cover both aspects. MAGMA ECONOMICS specifically supports customers in improving their product quality, reducing their costs and carbon footprint. Customers benefit by achieving quality and cost targets even before the first casting is produced.

Model rheocasting and thixomolding processes with MAGMAsemisolid

MAGMAsemisolid in MAGMASOFT® 6.1 is a specialized process module that takes into account the special conditions and rheology of semi-liquid melts for rheocasting and thixomolding processes.

The detailed analysis of the material distribution and the solidification behavior supports users in both developing new designs and optimizing existing processes.

In combination with other modules, such as MAGMAstress, MAGMAsemisolid enables a comprehensive optimization of the entire manufacturing process. As a fully integrated and powerful tool, it contributes to process transparency, maximizing the potential of these manufacturing technologies.

GIGA challenges – from the initial simulation of the gating system design to the early integration of mechanical properties into the virtual development chain

The dimensions and complexity of large structural die-cast parts, as well as the high investment costs for equipment and tools, place new demands on the development and design of casting processes.

MAGMASOFT® is the most comprehensive and powerful simulation tool for component, process, and tool design, whether for mega, giga, or tera castings!

Casting process simulation with MAGMASOFT® not only ensures the quality requirements of the GIGA casting, but also the robustness of tools and casting processes, and thus resource efficiency, competitiveness, and sustainability.

From ingate design to process layout – Secure your profitability with virtual systematic zincing!

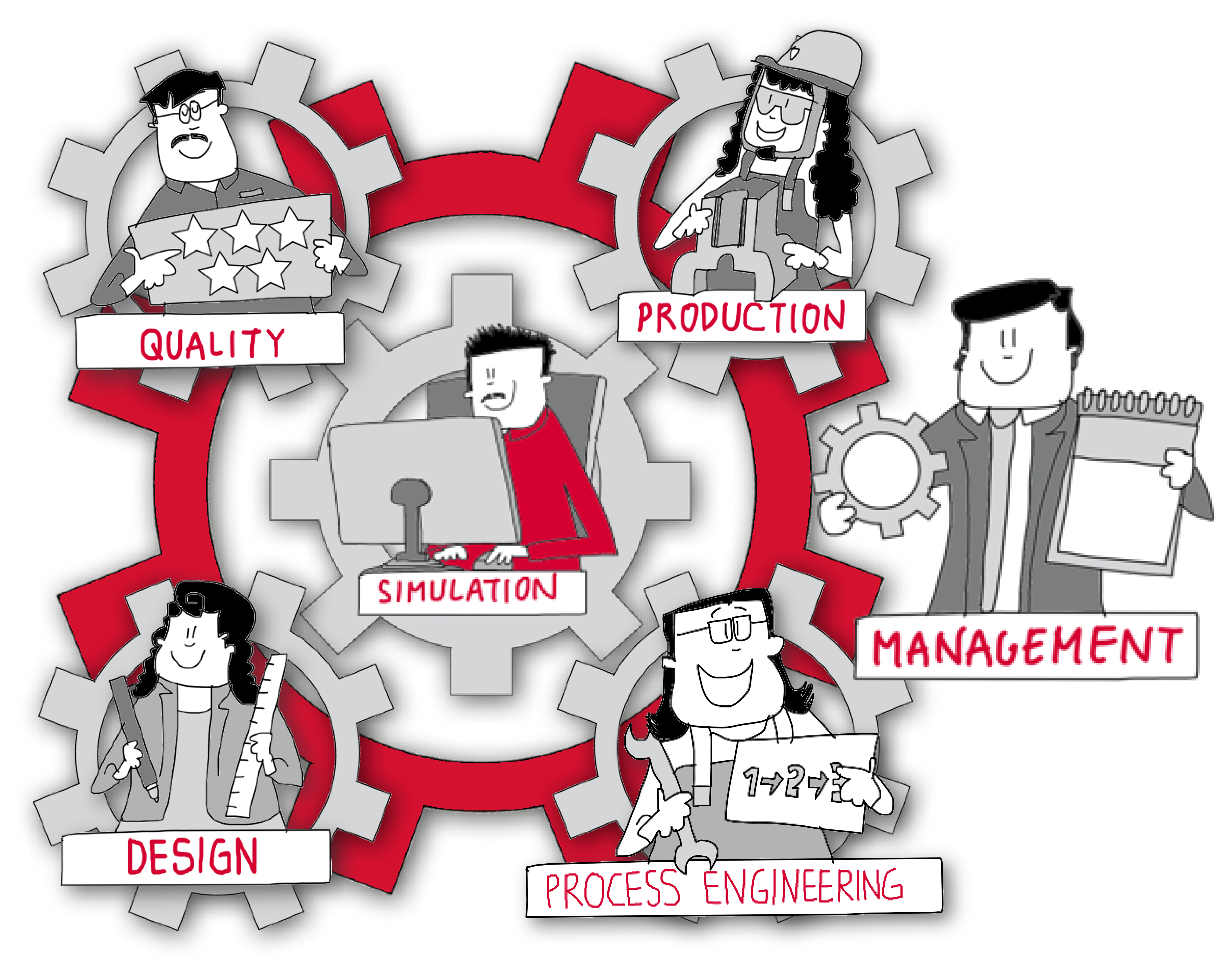

Unlocking Your Potential" - Implement MAGMASOFT® properly

Would you like to introduce casting process simulation in your company or implement it more efficiently?

MAGMA supports you as a partner with an individual implementation concept.

Our experts

- support you in successfully implementing MAGMASOFT® in your company processes,

- show you how to use MAGMASOFT® simulation results efficiently and communicate across departments,

- help you to successfully combine your simulation and process data and use it profitably for further projects and

- optimize the sustainability of your value chain with you.

Secure Your Personal Appointment Now

Would you like to introduce casting process simulation in your company or further deepen existing applications?

Then, make sure to arrange your personal appointment with our team now – quickly and conveniently.

We support you with a customized implementation concept, enabling you to fully unlock the potential of your processes.

We look forward to welcoming you in Nuremberg and having exciting discussions with you!

MAGMA lecture

- Druckgusstag 2026 – Thursday, January 15 - 11:00 a.m. (Room St. Petersburg, NCC Ost)

What’s up in Die Casting Simulation – there is more than just filling and solidification!

Horst Bramann, MAGMA Gießereitechnologie GmbH

[Read more]

General information

- Venue: Exhibition Centre, Nuremberg

- Date: January 13 - 15, 2026

- Opening times: 9:00 to 17:00

Come and visit us!

Hall 4, Booth 4-342

Floor plan: www.euroguss.de

Contact person

Do you have any questions about our trade fair presentation?

Please contact Ms. Stephanie Klein to arrange an appointment at the Euroguss 2026.

Phone: +49 241 88901 700