No Time to Lose

Tick tock, tick tock ... A glance at the clock shows us how quickly time flies. Technological change provides even more speed. Numerous tasks need to be completed at the same time. This increases the pressure on everyone to deliver the best quality in the shortest possible time – and this is also the case in the foundry industry.

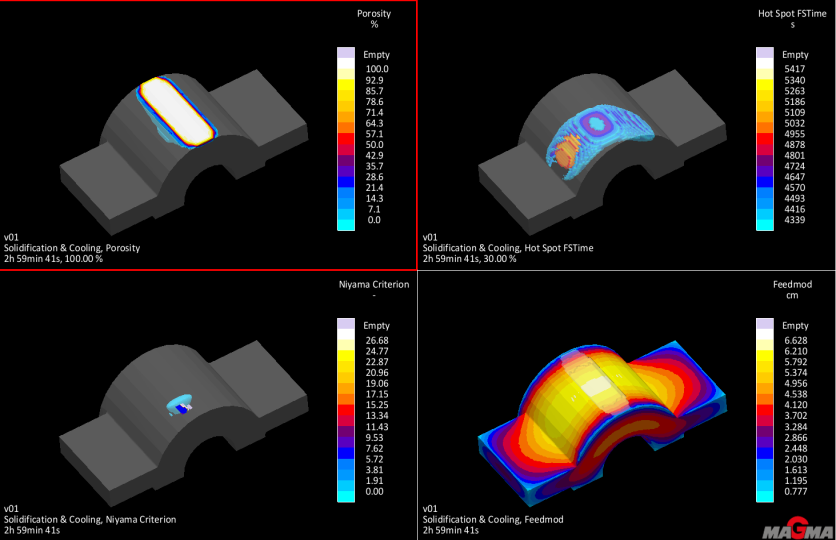

Especially when it comes to casting processes, many things need to be planned and coordinated in parallel. This is because changing one process parameter can affect many different aspects of casting quality. It is therefore a major challenge to optimize the casting process by evaluating the final casting quality while simultaneously pursuing quality and cost objectives. This is especially true for steel castings with their great diversity of grades, resulting microstructures and properties, and the multiple manufacturing steps for achieving the required quality – from metallurgy and casting, up to heat treatment and machining...

Press Service

For more background information or visual material, please do not hesitate to contact MAGMA:

Public Relations

Show email

Phone +49 241 88901 0