Together on the way to digital core production

Three leading technology providers in their respective fields, have successfully continued their long-standing partnership to develop digital core production: MAGMA Gießereitechnologie GmbH (MAGMA), specialist in the virtual optimization of foundry processes, Hüttenes-Albertus Chemische Werke GmbH (HA), leading supplier of foundry chemicals, and Laempe Mössner Sinto GmbH (Laempe), renowned manufacturer of core making equipment. The impressive progress attracted a lot of attention at GIFA.

In the production of modern, complex castings, it is important to achieve consistent quality in core production, which involves the interplay of several influencing factors and process variables. However, it is only at the end of the production process - when you have a finished casting - that you can determine whether the process can deliver 100% of the required quality. Foundries would certainly benefit from being able to identify potential deviations in advance, as this would give them the opportunity to intervene in the process at a very early stage.

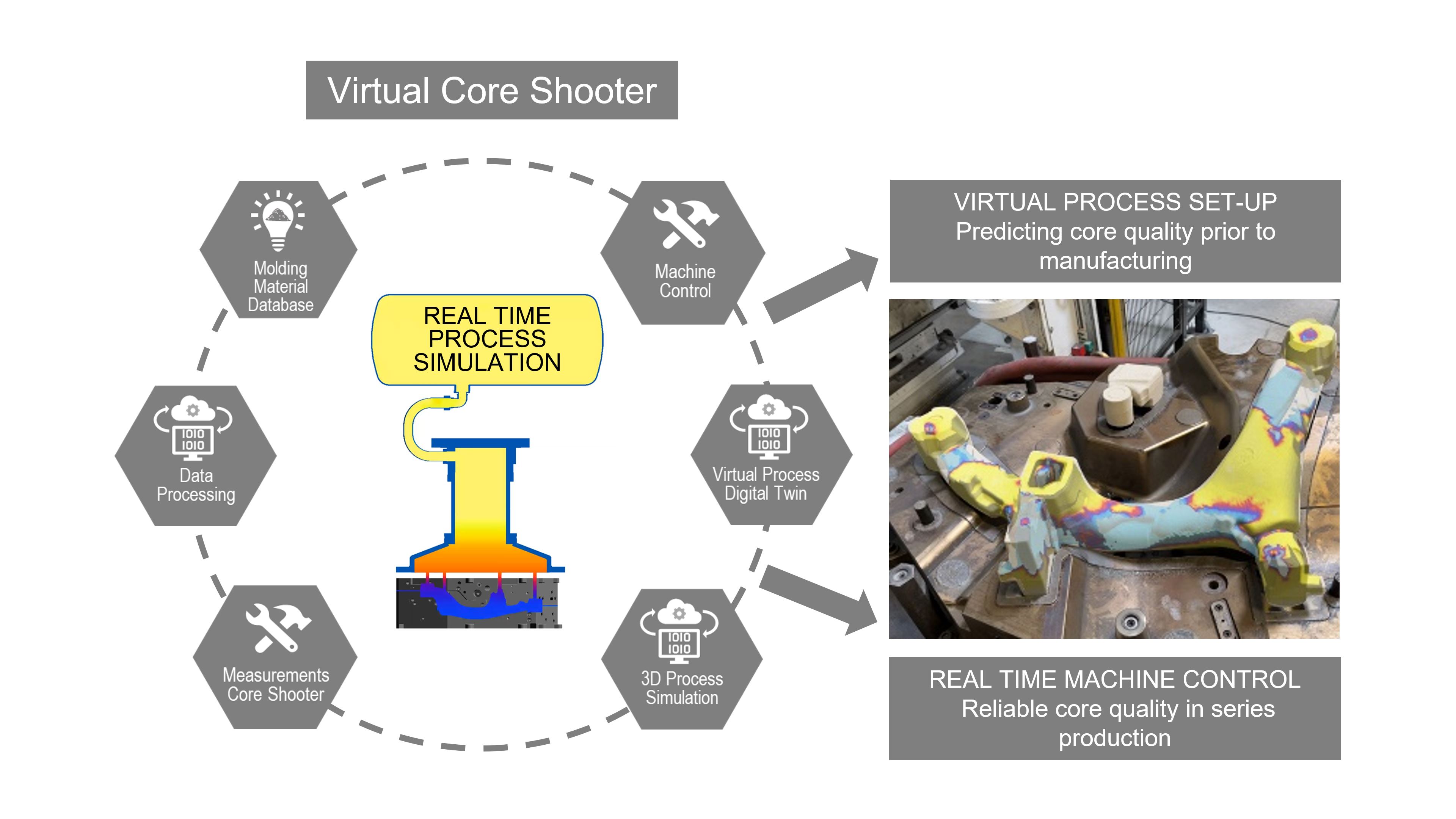

This is exactly what simulation-based mapping of core production does. It makes the process transparent and predictable, considering as many process parameters as possible. Integrating these methods into the production environment is the vision that drives the partnership between HA, MAGMA and Laempe.

The three partners introduced their revolutionary concept for the first time four years ago. At the leading international trade show GIFA in June 2023, the three partners presented the progress: The concept was illustrated on an extended machine control console of a Laempe core shooter. Visitors were able to digitally follow the production of a core on three interactive screens.

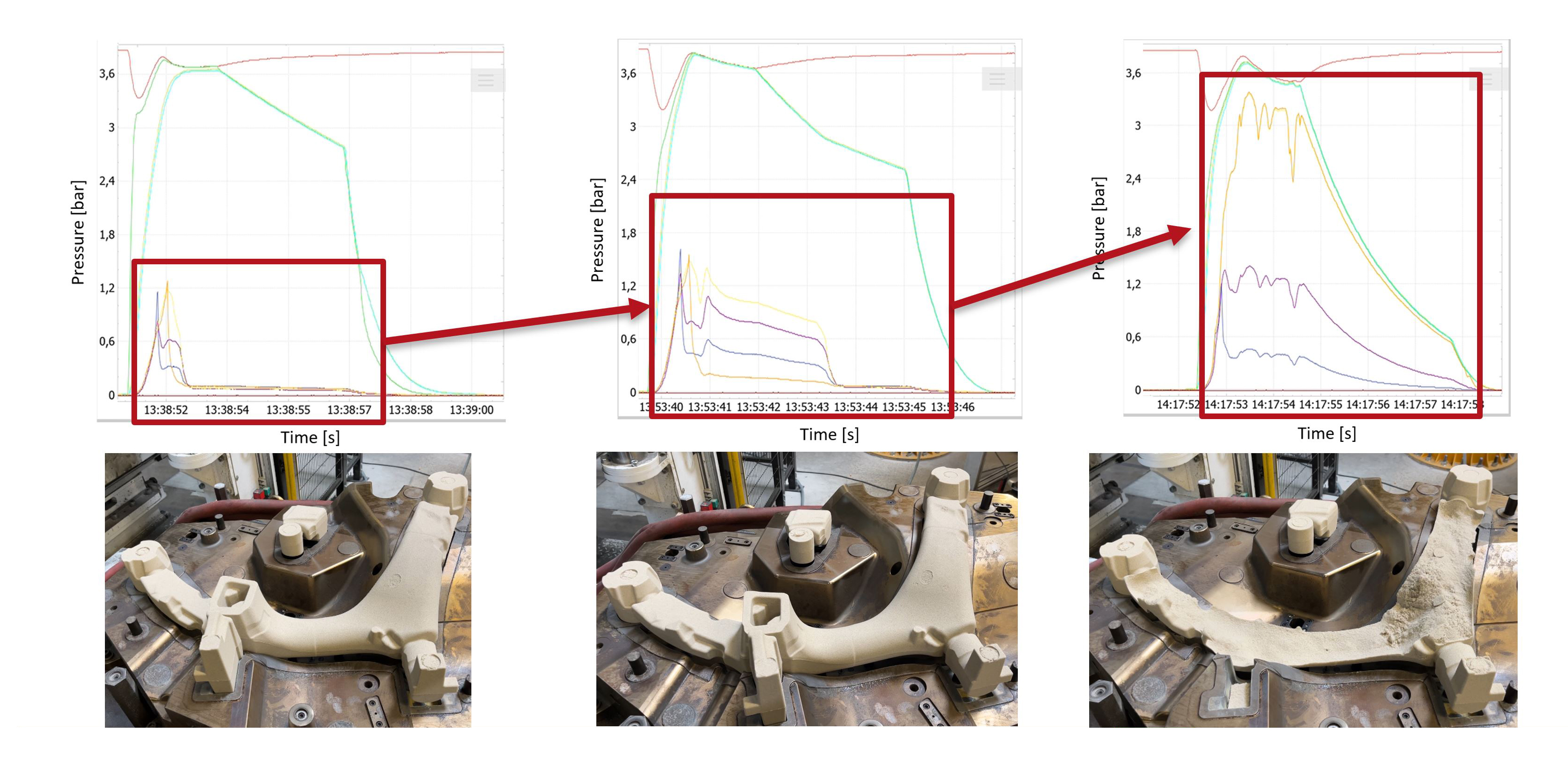

Various parameters of the core making process are continuously monitored and linked to real-time measurements taken in the machine. The data is processed in real time by a unique simulation software that predicts pressures and mass flows for the sand and air throughout the machine and core box system. As a result, the impact on core quality can be evaluated and controlled by making adjustments to the shooting process, answering questions such as: What is the effect of sand height in the shooting unit on the process? What is the effect of air vent blockage or cavity cleanliness? At what pressure is the sand shot into the mold cavity? How stable is the process and what parameters need to be changed if the set quality specifications are not met?

“With this patented new tool, we have been able to combine process simulation and real core production. By coupling the properties of the sand-binder mixture over the time with the core shooter and current tooling, we can simulate the entire process holistically. In this way, we ensure a reliable core quality”, says Dr Ingo Wagner, Product Manager Core Making Processes at MAGMA GmbH. "Due to the short computing times, it is even possible to integrate the simulation into the real-time operation of the machine. We are also implementing this technology as a front-end predictor into MAGMA C+M, our core making process simulation software”.

"For Laempe, this initiative is an important building block in our digitalization initiative, which we are supporting by our Laempe Digital Cockpit software suite and our Core Vision real time inspection system", comments Rudolf Wintgens, Managing Director of Laempe. "The now established link between process data, machine control and the final core distinguishes this approach from many Industry 4.0 activities in a foundry that lack the link to product quality."

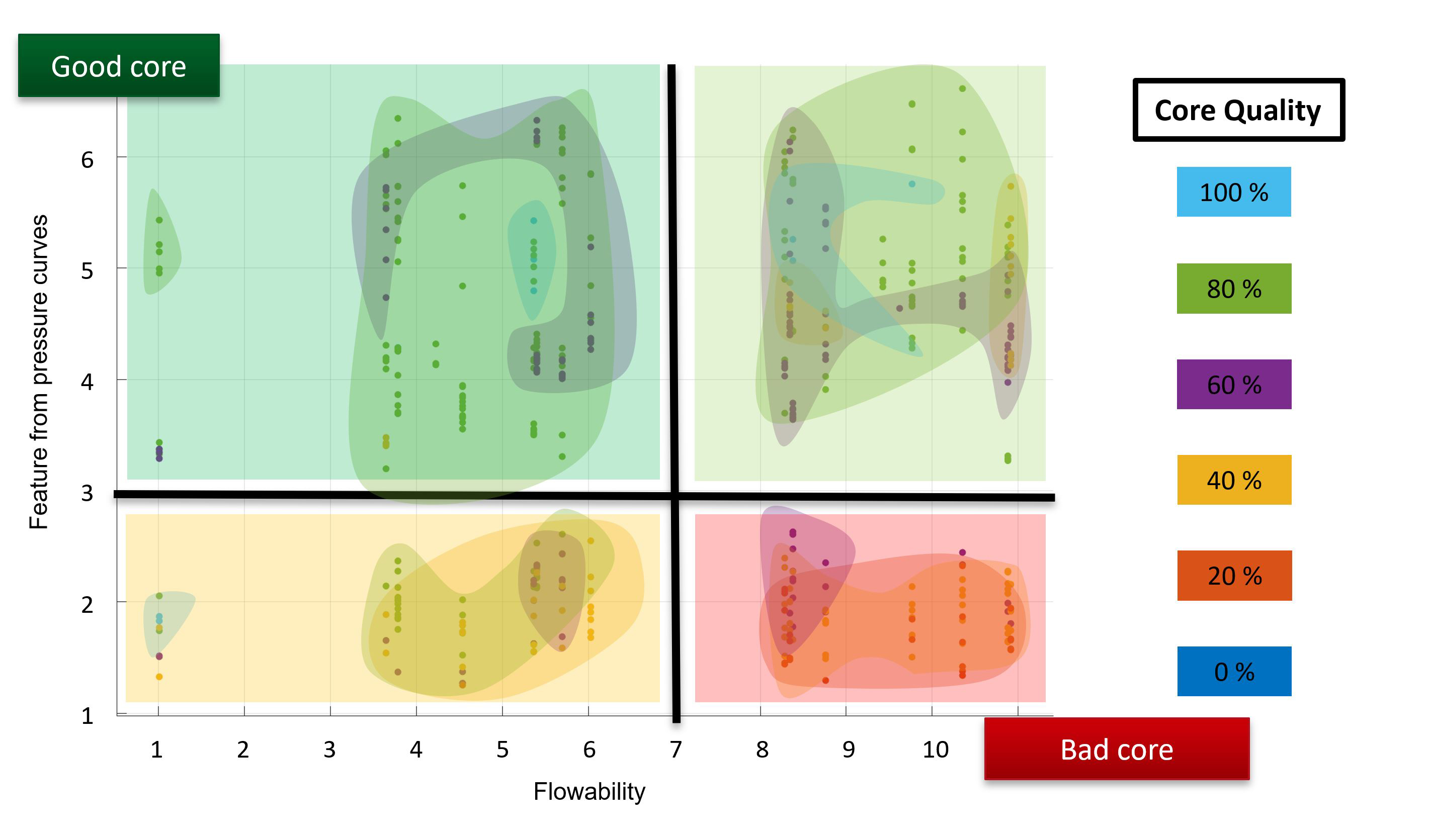

And the next step has already been taken: HA has invested in a comprehensive series of fully instrumented core making experiments to link the behavior of sand-binder mixture to the virtual system. The latest AI technologies have been used to establish a robust predictive capability between the state of the sand system at different machine settings and the final core quality. "We can now identify core defects that are not visible to the naked eye, but cause problems further down the process chain", explains Amine Serghini, member of the HA management team. "Deformation during core storage, core breakage during casting as well as casting defects are often not only caused by the binder itself, but also by parameters such as the storage time of the sand-binder mixture. A fresh sand mix flows better, has better compactability and ensures less tool deterioration and vent clogging". The virtual core shooter is used to predict whether a sand mix can still be used without causing downstream problems or how the production can be set to maintain good core quality.

The empirical data behind the direct simulations have been collected during tests at the HA Center of Competence (CoC) in Baddeckenstedt, Germany, on a state-of-the-art Laempe core shooter used there. This data allows important influencing parameters and their effects on the casting process to be accurately modelled in the machine and tooling. The CoC is equipped with a wide range of technical capabilities and provides a valuable platform for partners from different disciplines to systematically drive innovation in joint development projects.

The technical implementation of a real-time, physical and data-based core production control system has become reality thanks to the partnership between MAGMA, HA and Laempe and represents a revolutionary step towards Foundry 4.0. This approach opens a world of new possibilities for all three partners as they strive to provide their customers with intelligent solutions for optimized and robust core production at all times.

About the Hüttenes-Albertus Group

Hüttenes-Albertus (HA) is one of the world’s leading manufacturers of chemical products for the foundry industry. The HA brand stands for extensive service and a wide range of binder systems, coatings and further high-quality materials designed for the various mold and core making methods.

Founded over 100 years ago, Hüttenes-Albertus is, to this day, a solid and successful family business. The company has a strong, global network with about 1,800 dedicated employees in over 20 countries. Production sites, laboratories and sales companies on all continents ensure customer closeness and open up the range of the advanced HA technologies throughout the world.

Intensive research and development in the field of sustainable and environmentally friendly binder systems is the focus of all R&D and production activities. Living and operating today in a way that does not restrict future generations – that is the major task of our time. The HA Group is at the side of all customers and open to further projects.

Contact HA Group

Hüttenes-Albertus Chemische Werke GmbH

Wiesenstr. 23

40549 Düsseldorf

Tel. +49 211 5087 0 | Show email

About Laempe

Laempe Mössner Sinto GmbH is one of the world’s leading manufacturers of equipment for the core shop. The portfolio consists in sand preparation, core shooting machines for all chemical binder processes and the full range of automation around the core shop.

Beside conventional core shooting, Laempe also offers the latest technology for core printing with inorganic binder systems for high serial production.

In close cooperation with our customers, we develop customized solutions for individual request. Our world-wide networks offer service all around the world.

Contact Laempe

Laempe Mössner Sinto GmbH

Grienmatt 32

79650 Schopfheim

Tel: +49/(0)7622/680-0 | Show email

About MAGMA

MAGMA is a worldwide leader in developing and providing software for casting process simulation and virtual optimization. MAGMA stands for robust, innovative cast solutions and for reliable partnerships with the metal casting industry, including casting designers and buyers. MAGMA’s products unite the complexity of the casting process with user-friendliness to create economical solutions for its customers. MAGMA partners with its customers in the integration and effective use of the software, helping them to realize clear cost advantages.

MAGMA’s range of products and services includes the simulation software MAGMASOFT® autonomous engineering, for virtual designs of experiments and autonomous optimization of casting processes, as well as comprehensive engineering services for casting design and process optimization. Today, MAGMA’s software is used by more than 2000 companies all over the world for cost-effective casting production, reduced quality costs and for establishing robust processes for all applications, particularly in the automotive industry and mechanical engineering.

With the MAGMAacademy, MAGMA provides extensive implementation and educational offerings for all topics associated with casting process simulation. MAGMASOFT® users, together with their colleagues and managers, learn in trainings, workshops and seminars how they can use simulation and virtual optimization for optimizing casting design processes, lowering production costs and increasing resource efficiency.

MAGMA Gießereitechnologie GmbH was founded in 1988 and is headquartered in Aachen, Germany. A global presence and support are guaranteed by offices and subsidiaries in the USA, Singapore, Brazil, Korea, Turkey, India, China and the Czech Republic. Additionally, more than 30 qualified partners represent MAGMA around the world.

MAGMA Contact

MAGMA Gießereitechnologie GmbH

Mr. Michael Hutmacher

E-Mail: Show email

Phone: +49 241 8 89 01 - 703

Kackerstrasse 16-18, 52072 Aachen, Germany

You are welcome to use the information to update and inform your readers about MAGMA, free of charge. For feedback, comments and more information, please contact:

Free for publication, please provide copies of appropriate citation. MAGMA incurs no additional costs from publication.

Press Service

For more background information or visual material, please do not hesitate to contact MAGMA:

Public Relations

Show email

Phone +49 241 88901 0