Optimization of a Brake Caliper

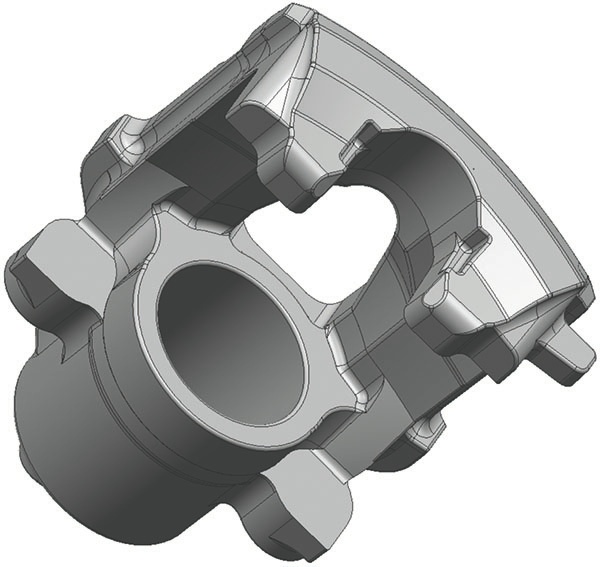

Due to safety reasons, brake calipers are produced to the highest quality requirements. The Shanghai Sandmann Foundry (SSF) developed, and is successfully producing a GJS car caliper which was acquired to be optimized in a DISAMATIC casting process.

At the time of acquisition, the caliper was being made in a six-cavity layout with the cylinder axis in a horizontal position. During mass production the amount of scrap had increased, especially due to unacceptable levels of shrinkage porosity and sand inclusions in the critical area of the hydraulic cylinder, discovered during X-ray examination. These defects were strongly influenced by the layout of the part in the mold. According to the engineers of SSF, a change of the casting orientation was required in order to produce the part economically, while fulfilling all quality criteria and following the given constraints.

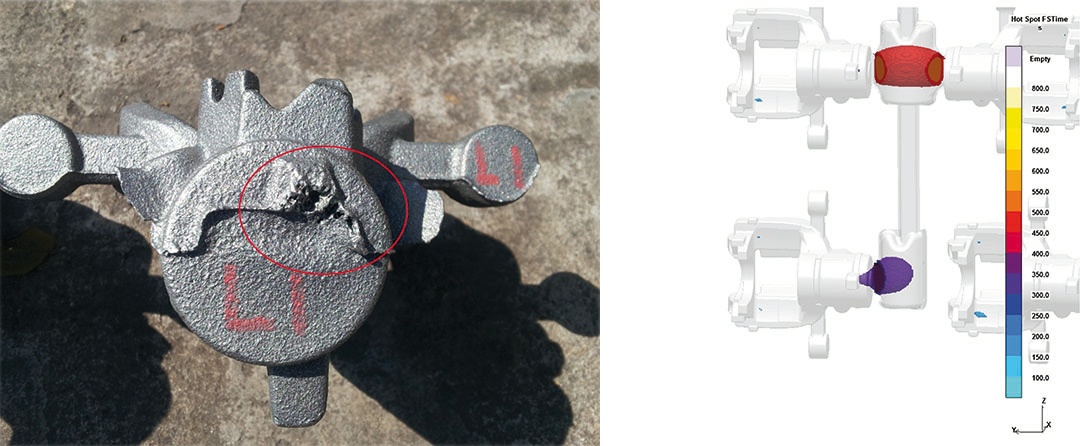

At the beginning of the optimization, the experts used MAGMASOFT® to understand the problem observed in the original layout. The tendency to form shrinkage porosity in the feeder neck area could be confirmed. However, eliminating the problems by simply making adjustments to the feeder or feeder neck was not possible, due to the technical constraints on the pattern.

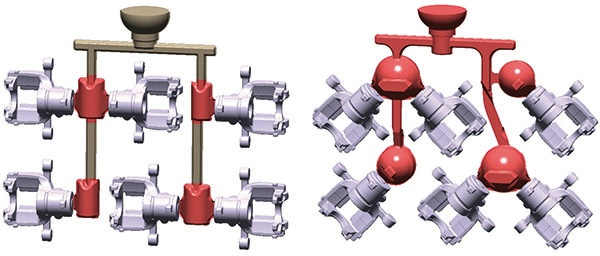

Therefore, further changes in the casting layout were necessary. Based on the experience of the SSF experts, the impact of rotating the component by 45° in the mold was assessed with the help of MAGMASOFT®. To rotate the parts, the feeders had to be changed to a spherical shape, something that SSF had already been using successfully for other castings. These modifications helped to shift the porosity away from the critical area. However, the change also had a negative impact on the mold filling. An increase in turbulence during filling was observed, which led to a higher risk of sand inclusions.

To also solve this problem, the impact of an additional overflow and various geometries for gating and feeding had to be checked. Through traditional simulations, this would have resulted in several versions and a lot of manual work, but the experts at SSF made use of the new methodology of Autonomous Optimization in MAGMASOFT®, which played a crucial role in finding the optimal design.

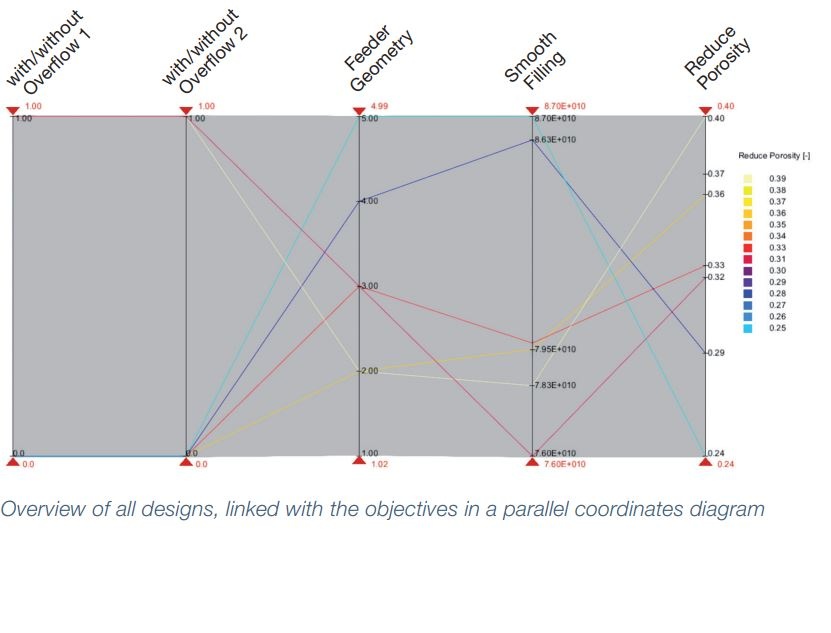

The optimization parameters were parametric geometries for the feeders, gates and optional overflows. With this, 10 designs were defined and calculated automatically as a virtual experiment in MAGMASOFT®. At the same time, a smooth filling and minimum of porosity were specified as objectives for the optimization.

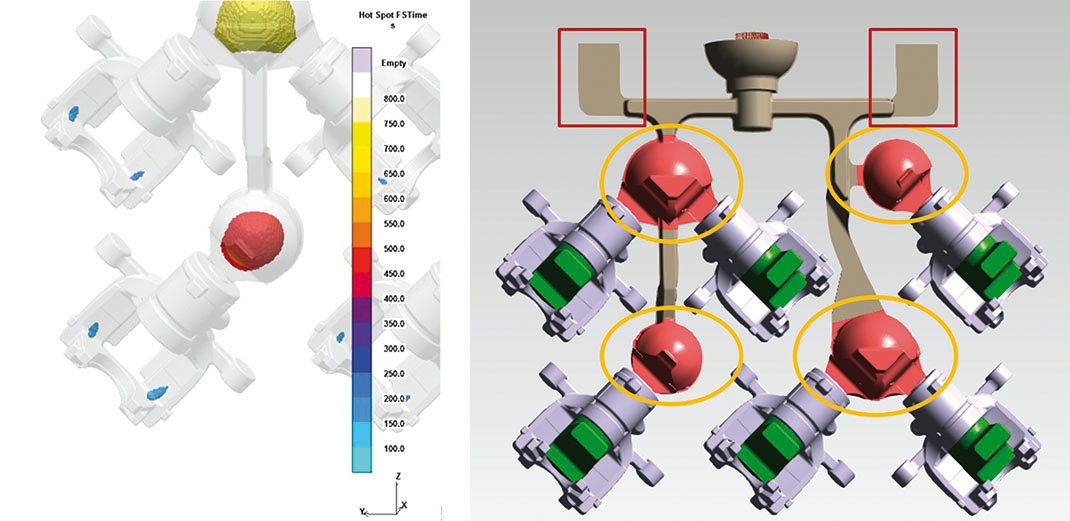

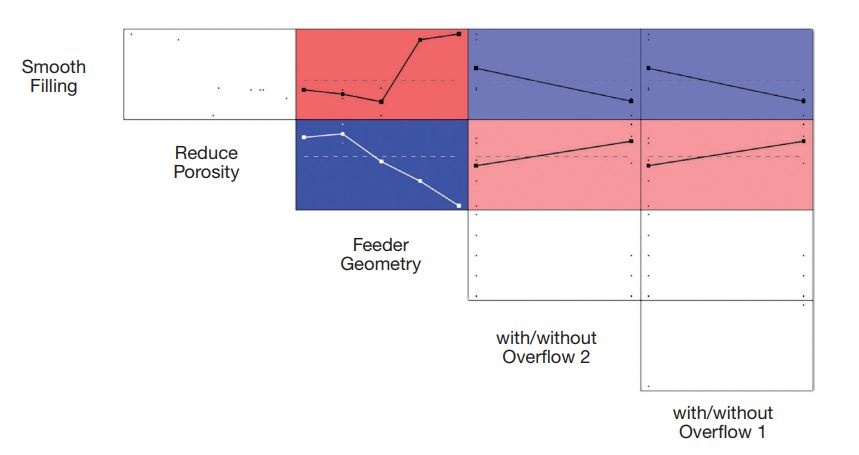

With the help of the statistical tools in the assessment perspective of MAGMASOFT®, the engineers were able to evaluate the complex filling behavior efficiently and within a short period of time. While a traditional comparison of conventional 3D results did not allow clear conclusions, the experts were able to identify the main influencing factors on the casting quality by using the correlation matrix. In addition to this, the optimal solution was quickly determined with the help of the parallel coordinates diagram.

In the correlation matrix, the comparatively small influence of the overflows on both an optimized feeding and a smooth filling was made visible. By contrast, the feeder size had a much more significant impact. Through an increase of the feeder volume by 3%, the best compromise for both objectives was identified. The final X-ray examination of the castings which were produced with the modified design delivered a positive result for all areas.

The systematic investigation of various options by the Sandmann experts built the basis for a successful mass production of the caliper. Through the implementation of the optimized layout for an annual production of about 840,000 sound castings, around 384 tons of raw materials could be saved. Reduced machining work and energy savings led to more than 75,000 € in savings, and the scrap rate was reduced by a factor of 10.

The Shanghai Sandmann Foundry (SSF) Co., Ltd

The Shanghai Sandmann Foundry (SSF) Co., Ltd. is a subsidiary of HUAYU Automotive Systems (Holdings) Co., Ltd., located in the International Auto City Anting Shanghai. They manufacture GJL, GJS and CGI castings for the automotive industry, with an annual production of 160,000 tons and a turnover of 1.9 billion Euros. Production is mainly performed on three DISAMATIC® lines and one HWS line. They also have a dedicated test foundry and a shell molding facility. Customers of SSF include automotive OEMs worldwide.