Optimization of Steel Casting Design and Methoding

Hot tearing is one of the main defect sources in steel castings. However, the cost-intensive repair work created by this defect can be avoided by reviewing the influence of casting design and methoding on the formation of hot tears.

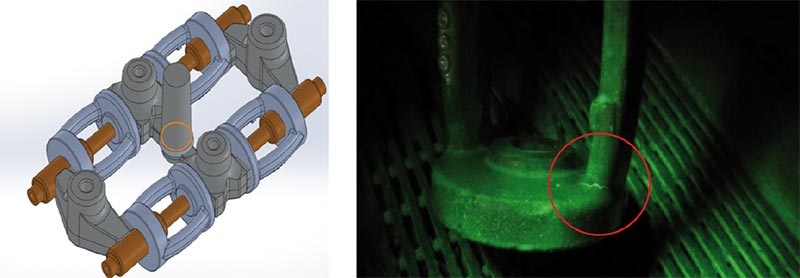

Prior to optimization, the featured shell molded steel casting produced by Eagle Alloy had hot tears in the inner corners of the longitudinal braces in 80% of the castings that were produced. The tears required extensive re-work, including repair welding of the defect locations. In addition, it was necessary to carry out a magnetic particle inspection to check all of the castings produced. As a result, the cost to produce this casting using the existing tooling was not favorable.

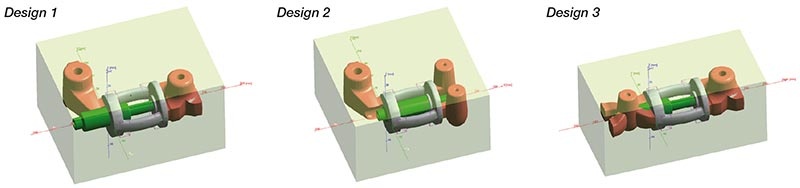

Eagle Alloy concluded that in order to optimize production, it was necessary to work out and verify changes both in the casting design and in the gating and risering. To tackle this task in a timely and cost-efficient manner, they began examining different variants using the capabilities of autonomous optimization in the newest version of MAGMASOFT®. The following tasks were assigned to the software as objectives: first, hot tears in the problem area should be prevented; secondly, the necessary changes should not decrease the soundness of the part by creating shrinkage porosity defects. To achieve these objectives, both the part geometry and the feeding system were varied and autonomously exchanged in a design of experiments (DoE) in MAGMASOFT®. In doing so, the solidification and cooling of the part to ambient temperature, including the resulting stresses and crack susceptibility, were analyzed for each combination of the different casting designs and riser configurations. The corresponding quality criteria for feeding and the susceptibility to hot tearing were autonomously evaluated in the critical areas.

A total of 12 different solutions were developed and analyzed. For this purpose, the position of the casting, the casting geometry, the feeder configuration and the process parameters were modified.

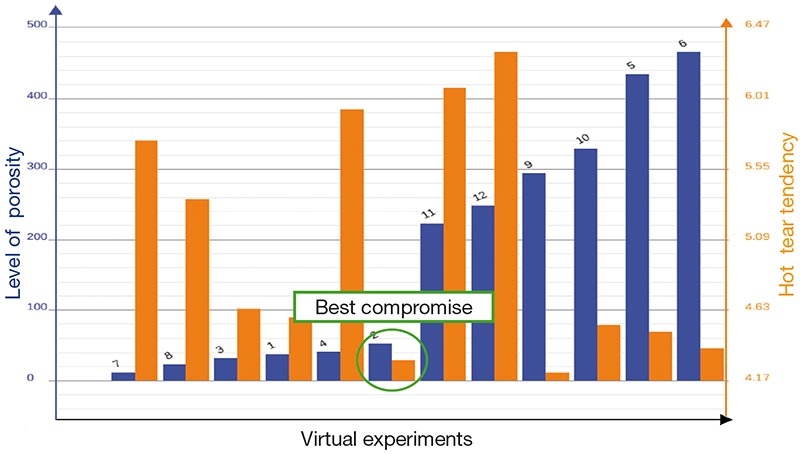

For the evaluation of the optimizations, the engineers made use of the statistical and result analysis tools available in the software to identify the best available designs.

A bar chart quickly displayed both defined objectives for each considered design. In doing so, opposing trends regarding porosity and hot tearing became obvious.

The strongest tendency for hot tearing was revealed for an optimum feeding with minimum porosity. This is due to longer solidification times and increased temperature differences between the casting and the feeders, which promotes feeding, but also results in high strain rates and an increased tendency for hot tearing. The bar chart also allowed the engineers to quickly identify a design that provided the best compromise between the two competing objectives.

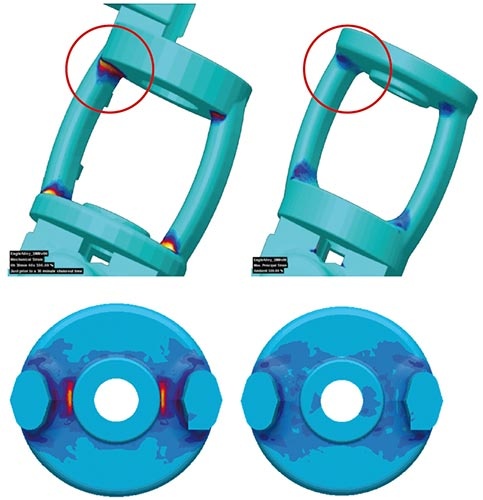

A comparison of the results between the original situation and the best design considered in the optimization showed that geometric changes in both the casting and in the feeding system were necessary to significantly reduce the stress and porosity defects at the same time.

By adopting this solution, it was possible to reduce the stresses and the plastic deformations in the critical solidification range by 61% compared to the original situation. The assessment tools in MAGMASOFT® allowed for a quantitative determination of how each design variable impacts each of the objectives. In this case, the riser changes resulted in a 30% reduction of strain during solidification, while the modified casting design reduced the strain during solidification by 44%.

Thanks to the positive results, it was possible to reduce both the amount of magnetic particle inspections required as well as the amount of re-work time. The calculation of these 12 versions was done on an 8-core workstation and took 22.5 hours. To run samples in production to test all 12 versions would have taken weeks, with material and labor costs that could not have been justified. Without optimization to quickly consider all 12 designs, the changes made to the tooling would not have been possible in this case.

The systematic use of autonomous optimization at Eagle Alloy has contributed substantially to enabling the cost-effective production of quality castings for this case study.

Eagle Alloy, located in Muskegon, Michigan, USA, was founded in 1979 to meet the needs of customers looking for a short-run steel and stainless steel foundry. Today, Eagle Alloy is a medium to high production steel foundry that competes globally and is considered to be one of the finest overall steel foundries in the USA. In 1991, Eagle Precision Cast Parts was founded to serve customers looking for the finest investment castings in the shortest period of time. In 1999, it was decided that the demand by customers for completely machined product was strong enough to invest in a full-service machining facility. In 2002, the group expanded by the acquisition of an existing aluminum foundry that had the ability to build patterns. A new facility was built to house the permanent mold portion of Eagle Aluminum Cast Products. The shell mold process of Eagle Alloy offers tight tolerances with excellent dimensional repeatability, ensuring consistency from one order to the next. The airset molding line is used to produce low quantity production runs. It is also beneficial for providing quick prototypes before a shell pattern is produced. In-house X-ray, advanced quality and delivery programs, a complete machining facility, and the use of MAGMASOFT® since 2007 are only part of what makes Eagle Alloy unique in the US steel casting industry. In 2015, Eagle Alloy was named ‘Metalcaster of the Year’ by Modern Casting Magazine.