Stresses That Could Bring You to Boiling

A boiler manufacturer approached MAGMA with a problem where a casting had failed in use. The casting process was suspected to have generated residual stresses or hot tears, eventually leading to the failure.

A thorough evaluation of the entire casting process, including the simulation of residual stresses during cooling, showed that the casting process didn’t create any critical conditions related to casting defects, hot tears or residual stresses.

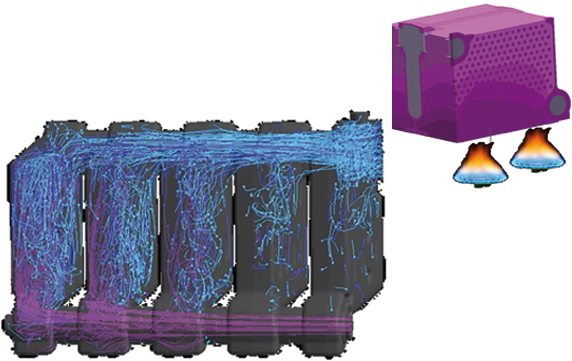

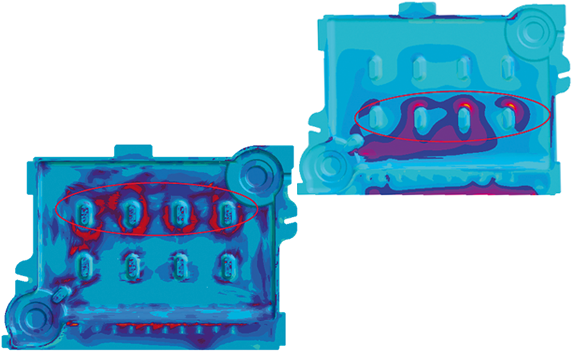

MAGMASOFT® was then used to simulate the stresses induced in the casting during its use. The water flow through the boiler assembly, as well as the heat created by the burners and flue gases, had to be considered to simulate the heating and cooling cycle of the casting, where the biggest temperature differences occurred. The simulations confirmed elevated stresses, about 2/3 of the tensile strength of the gray iron, in the area where the part failed. Over time, these elevated stress levels fatigued the area. From this point, the boiler company evaluated several new designs and implemented design modifications to assure a sufficient lifetime of their boilers.