MAGMA ECONOMICS: Keeping Both Sustainability and Profitability in Focus

MAGMA ECONOMICS offers an innovative perspective within MAGMASOFT® that allows users to quantitatively evaluate the economic and ecological impact of different process variants directly in the software. Based on already defined geometries, materials and process data as well as simulation results, MAGMA ECONOMICS calculates and compares in detail costs, energy consumption and CO₂ emissions across different scenarios.

MAGMA ECONOMICS

MAGMA ECONOMICS:

- Technology Meets Economics

Evaluate your casting processes both technically and economically – seamlessly integrated into MAGMASOFT®. - Confident Decisions

Make informed decisions early in the design phase with accurate data on cost, energy, and emissions. - Clear Cost Drivers

Identify savings potentials by comparing cast geometry, gating, and process parameters – without additional simulations. - Sustainability Made Measurable

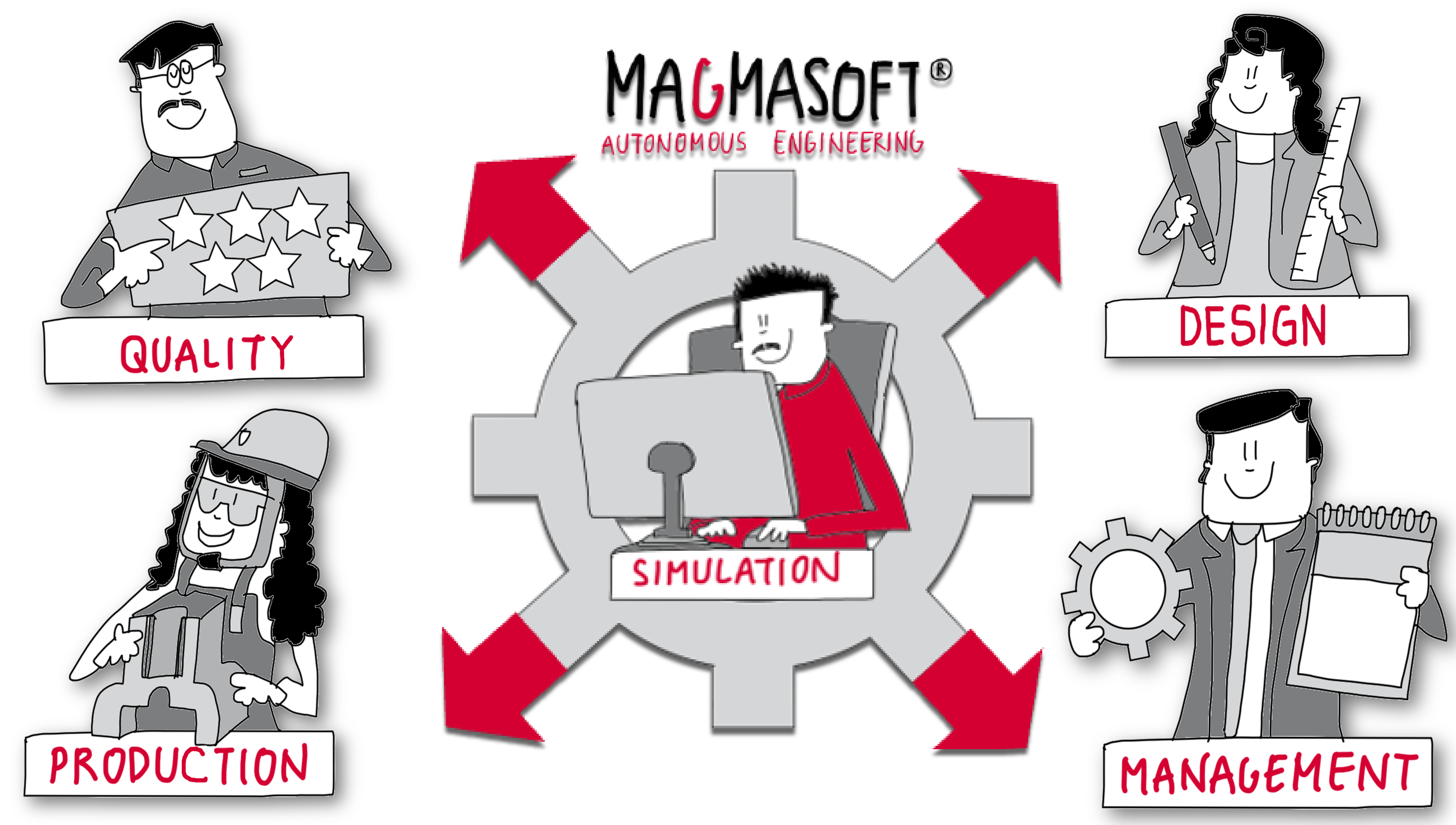

Optimize CO₂ emissions and energy consumption in line with your sustainability strategy. - Cross-Department Value

Use MAGMASOFT® to provide unified insights for engineering, purchasing, and management – all within one platform.

- New perspective: MAGMA ECONOMICS enables the quantitative evaluation of costs, energy consumption and CO₂ emissions together with quality criteria directly in MAGMASOFT®.

- Database: The assessments are based on the geometries, materials and processes available for the simulation as well as the simulation results.

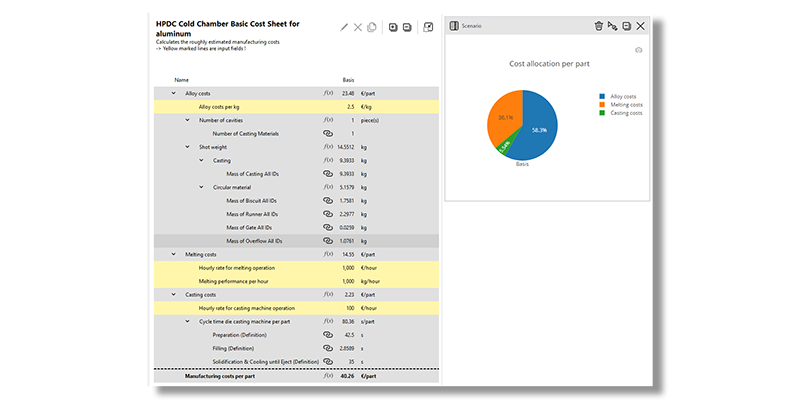

- Customizable templates: Templates for common materials and processes contain specific cost and emission factors.

- Comprehensive analysis: detailed analysis of resource consumption and production costs along the entire casting process

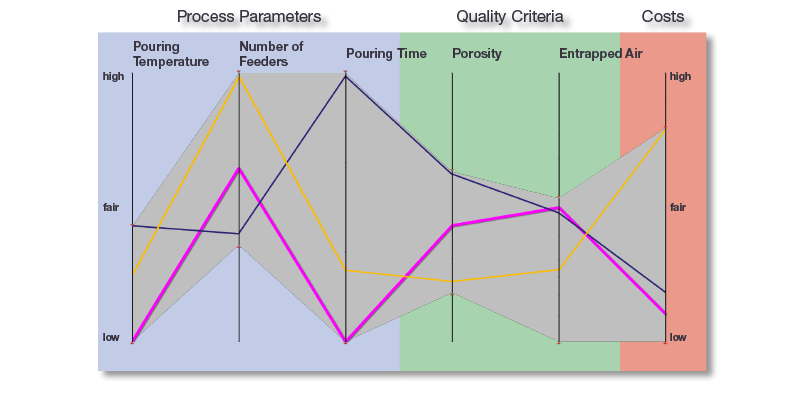

- Scenario comparison: It is possible to vary process parameters individually and to compare different scenarios without additional simulation time.

- Integrated solution: fully integrated into MAGMASOFT®, no additional modules or licenses required

- Autonomous engineering: seamless integration for optimization and virtual design of experiments

- Comprehensive evaluation: simultaneous evaluation of quality, productivity, project costs and carbon footprint for all processes and applications

MAGMA ECONOMICS is a new perspective in MAGMASOFT® that supports users in quantitatively evaluating the economic and ecological impact of process variants. MAGMA ECONOMICS calculates and compares costs, energy consumption and CO₂ emissions of different scenarios. The perspective draws on existing geometry, material and process data as well as simulation results.

MAGMA ECONOMICS utilizes key information from MAGMASOFT® to enable a comprehensive assessment of cost and resource targets without compromising quality.

Centralized Information on the Casting Process

MAGMA ECONOMICS integrates data from various elements of the casting process, such as casting/core components, molds/tools, machines and materials. Quantitative data on volumes, quantities, masses, surfaces and interfaces provide a comprehensive understanding of the process.

Process Knowledge

MAGMA ECONOMICS takes into account key process data such as time-related metrics, heating and cooling media and consumables. This comprehensive view helps to improve decision-making.

Unique MAGMASOFT® Results

MAGMASOFT® generates technical information that serves as the basis for evaluating economic factors in MAGMA ECONOMICS. These results include casting times, feeding requirements, required cycle times (including shakeout and ejection times, cooling times and curing/drying times) as well as heat and energy consumption quantities throughout the manufacturing process.

MAGMA ECONOMICS is fully integrated into MAGMASOFT® and is highly customizable. You can use the simulation results at all levels of the organization to create added value for all stakeholders.

Quality vs. Yield

Balance quality requirements with production cost considerations

Cycle Time and Productivity vs. Energy Consumption

Find the most efficient path between productivity and energy consumption

Natural Feeders vs. Exothermic Sleeves

Determine the most cost-effective feeding solution that meets your casting requirements

Chill Use vs. Additional Feeding

Cost evaluation of chills compared to additional feeders to achieve the required quality

Mold Design and Gassing Rates

Optimize your core gassing process to minimize costs and improve overall casting performance

Core Box Heating vs. Gas Flow

Explore the trade-off between core box heating and gas flow through the core for inorganic cores

Pattern Plate Design and Production Time

Find the optimum between annual cost savings and production efficiency

Production Volumes and Cost per Part

Gain insight into the cost dynamics at different production levels and optimize your operations accordingly

CO2 Footprint Analysis

Quantify the carbon footprint for different production volumes. Understand the environmental impact of your casting processes and identify opportunities for sustainable improvements

Cost Savings vs. Simulation Effort

MAGMA ECONOMICS expands technical optimization with MAGMASOFT® to include economic criteria. This allows identifying savings potentials that have previously been scarcely considered in purely technical assessments. By strategically utilizing simulation results, additional opportunities arise as a management tool. MAGMA ECONOMICS enables informed and well-supported decisions – both technically and economically.

Unlock your potential with MAGMA ECONOMICS – the key to casting process optimization, cost-efficiency and resource conservation in one tool.

Use MAGMA ECONOMICS to Consider and Evaluate MAGMASOFT® Simulation Results for Die Casting

Use MAGMA ECONOMICS to Consider and Evaluate MAGMASOFT® Simulation Results for DISA

Use MAGMA ECONOMICS to Consider and Evaluate MAGMASOFT® Simulation Results for Steel

MAGMA ECONOMICS

Optimized Casting Quality, Cost and CO2 Footprint

Latest Publication

MAGMASOFT® 6.1 – Efficient Optimization of Processes and Profitability

With new functionalities and extensive enhancements, MAGMASOFT® 6.1 offers comprehensive support for optimizing low pressure die casting processes and facilitates the design of die-cast parts. A specially developed process module for rheocasting and thixomolding processes adds numerous new options for users in core production and continuous casting.

In addition, the newly introduced ECONOMICS Perspective enables, for the first time, a quantitative evaluation and optimization of both costs and CO₂ emissions for all simulation projects, improving both the profitability and the sustainability of all applications.