Optimization of the Cooling of a Die

The layout of the tempering system for a high pressure die cast transmission case was performed using experience gained from other similar castings. Quality problems were experienced due to die temperatures that were too low.

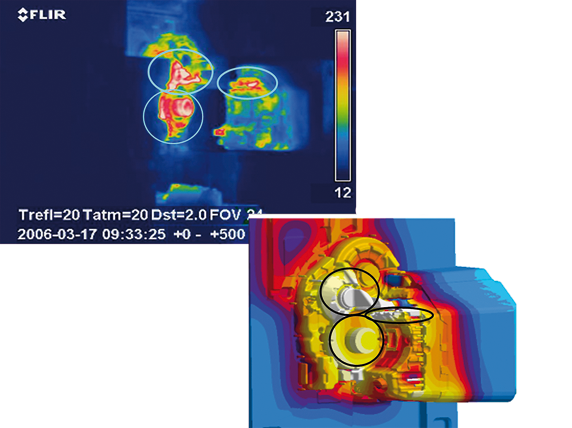

A quantitative analysis of the die temperatures was carried out using MAGMASOFT®. In the simulation, the sizes and types of cooling channels were accurately defined, as well as the flow rate of coolant. As a check of the simulation results, a thermocouple was inserted in the die and infrared photos were made.

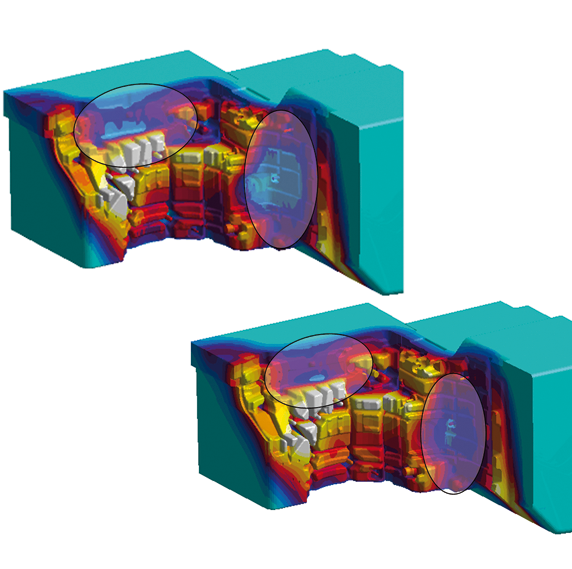

To optimize the cooling channel layout, an analysis of the effectiveness of the cooling channels was performed.

As a result, the cause of the problem was identified as inhomogeneous temperatures due to overcooling at some locations. Some of the cooling lines were changed or removed and the effects of these changes evaluated using simulation.

The end result was an improvement in cast quality through a more homogeneous temperature distribution.

* Courtesy of HYUNDAI-KIA MOTORS, Korea